Hitachi Launches AI Agent for Manufacturing Equipment Diagnostics in HMAX Industry

Hitachi Launches AI for Manufacturing Equipment Diagnostics

Hitachi, Ltd. has unveiled its latest innovative solution, Field Support AI Navi, an AI agent designed to support the diagnosis of manufacturing equipment failures. This technology, now part of the HMAX Industry product lineup, empowers factory maintenance personnel to identify issues during the inspection of production equipment. Using tablets, they can query the system, which promptly offers potential causes and solutions.

With a unique mechanism, Field Support AI Navi guides maintenance staff on the next steps to take even when faced with new and unfamiliar situations. The AI is designed to cater to various types of equipment and devices commonly found in manufacturing environments, including power equipment, control devices, pumps, and valves. Currently, it has undergone trial operations and collaborative verification in major manufacturing companies, showcasing its reliability and effectiveness.

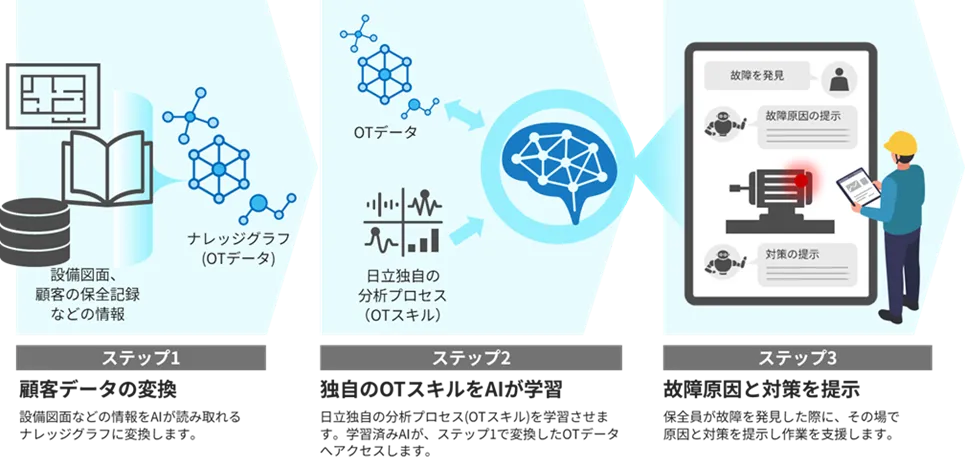

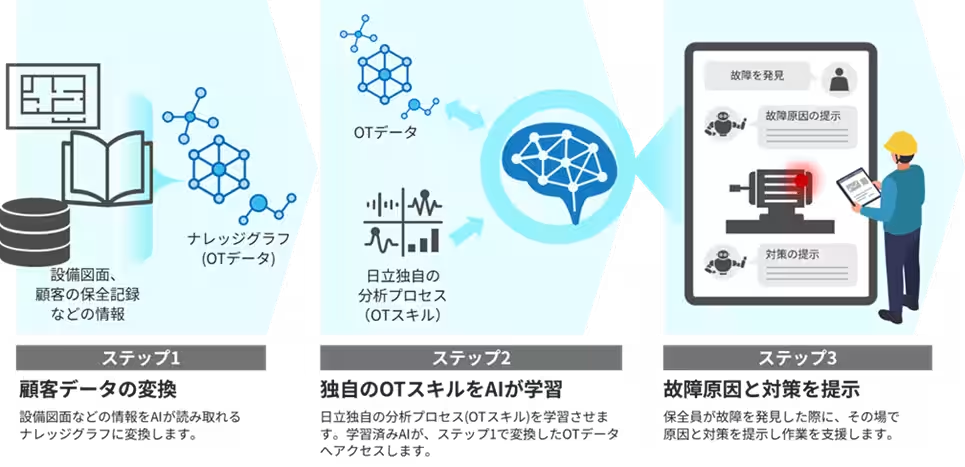

How It Works

The solution operates by transforming blueprints of various production and utility equipment that customers have accumulated into a format that can be processed by generative AI knowledge graphs. This means that the knowledge graph, along with operational technology (OT) data, is integrated into Hitachi's proven equipment failure cause analysis methods, namely STAMP (System Theoretic Accident Model and Processes). Consequently, the AI can offer diagnostics meeting or exceeding those of an experienced maintenance technician.

Field Support AI Navi offers multiple deployment options tailored to customer needs. For instance, organizations looking to enhance their existing systems can implement it as API as a Service (APIaaS). For those wanting to expedite deployment, a packaged system is available for more accessible integration into production environments.

Addressing Labor Shortages

Manufacturing industries face increasing challenges such as a decreasing working-age population and the decline of experienced technicians, compounded by the globalization and expansion of production sites. As the demand for skilled workers rises, addressing labor shortages becomes critical. The transfer of skills and alleviating the workload on frontline workers in manufacturing environments is urgent.

Hitachi leverages its strengths in IT and OT integration to provide solutions through Lumada, utilizing extensive domain knowledge gained through collaboration with a diverse range of manufacturing clients. The HMAX Industry suite represents Hitachi's commitment to deliver next-generation solutions combining vast installation data from digitalized assets with advanced AI, a strategic focus within the Integrated Industry Automation initiative aimed at scaling these innovations across growing industries.

HMAX Industry embodies the essence of Lumada 3.0, paving the way for transformative advancements for frontline workers in manufacturing sectors. By providing tools and insights to optimize equipment maintenance, Hitachi is set to revolutionize the manufacturing landscape.

Future Aspirations

In the future, Hitachi envisions a seamless integration of real-time data collection and analysis in operational settings, evolving toward a more comprehensive Physical AI framework. This holistic approach is aligned with the company's mission to contribute significantly to solving today's pressing challenges in the manufacturing sector.

As industries continue to digitize and transform, solutions like Field Support AI Navi not only enhance operational efficiency but also contribute to sustaining essential skills within the workforce, ultimately driving innovation in manufacturing and beyond.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.