Robit Showcases Innovative Inspection Solutions at Automotive World 2026

Robit Showcases Innovative Inspection Solutions at Automotive World 2026

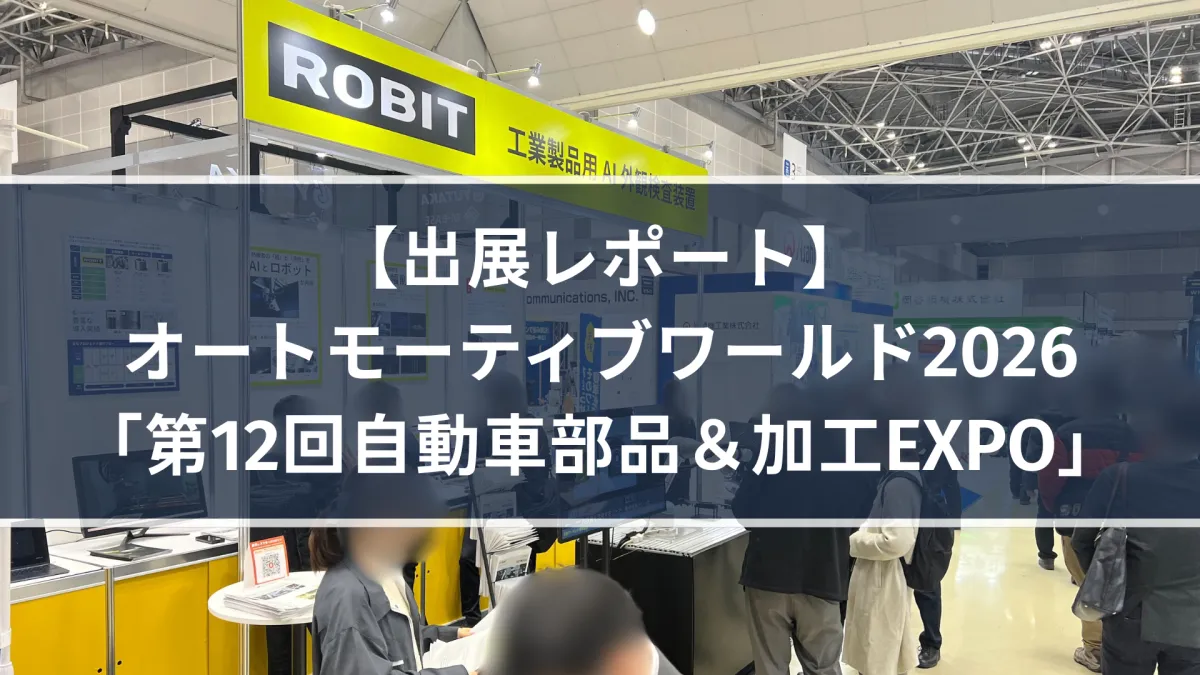

From January 21 to 23, 2026, Robit Inc. participated in the Automotive World 2026 at Tokyo Big Sight, engaging with over 1,000 visitors during this three-day event. The company unveiled its state-of-the-art TESRAY solutions, which integrate AI, software, and hardware to revolutionize quality inspections in the automotive sector.

Event Overview

The Automotive World 2026, organized by RX Japan, featured various exhibitors demonstrating the latest trends and technologies in the automotive industry. Robit's participation highlighted its commitment to enhancing automation within quality checks, especially in processes that have traditionally relied on human sensitivity.

Exhibited Technologies

Robit's display focused on two main product lines: the TESRAY S Series and the TESRAY G Series.

1. TESRAY S Series: Advanced Inspection for 3D Shapes

The TESRAY S Series is designed for high-speed and high-precision inspections of complex industrial parts like automotive components. This solution promises to elevate quality control standards in the industry by enabling high-speed scanning, synchronized AI analysis, and feedback mechanisms that identify and rectify underlying production issues.

- - High-Speed Scanning: Utilizing robotic movements synchronized with AI analysis ensures a quick and stable inspection process.

- - Quantifying Sensitivity: This AI algorithm identifies subtle variations in painted surfaces, which traditionally required expert judgment.

- - Feedback for Process Improvement: The system connects detected anomalies to production points, thus facilitating upstream improvements in manufacturing processes.

2. TESRAY G Series: Fast and Accurate Sorting Solutions

TESRAY G Series targets not only food items like nuts and fish but also small industrial components such as metal washers and plastic pellets with efficient sorting capabilities.

- - Omnidirectional Inspection: Using air drop technology, this series captures detailed images from all angles during a brief drop, allowing for comprehensive inspections.

- - Multilevel Sorting based on Defect Severity: This patented feature doesn’t just classify items as pass or fail; it assesses damage levels and allows for optimizing utilization depending on the severity of defects.

- - Precision in Color and Shape Recognition: Advanced capabilities to eliminate contaminants resembling good products are included, ensuring high-quality outputs.

Reception and Impact

The enthusiastic response to Robit's booth underscored a strong interest in advanced technologies for manufacturing DX (Digital Transformation) and quality control automation. Engaging directly with manufacturing professionals, Robit gained invaluable insights into the challenges faced on the factory floor.

The discussions underscored the critical role of AI in enhancing operational efficiencies and quality checks in the automotive manufacturing sector. Witnessing firsthand the pressing issues and operational scenarios allowed Robit to refine its solutions and reinforce the company’s commitment to providing real-world technological support.

About Robit Inc.

Founded in June 2014 and headquartered in Itabashi, Tokyo, Robit Inc. specializes in the design, manufacture, and sale of robotics, precision machinery, related hardware, and software.

Check out their offerings at Robit. As they continue to innovate, Robit aims to respond to the growing demand for sophisticated quality assurance in the automotive industry while enhancing production processes and supporting manufacturers more effectively.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.