The Shift Management Revolution at Geo Store: A Model for Success

Introduction

The Geo Group operates approximately 2,000 stores nationwide, facing the challenge of differing store sizes and types while optimizing staff allocation through "operational planning" and "task assignment." Prior to the implementation of a unified system, shift planning and task distribution were developed individually, leading to difficulties in visualizing workload and analyzing data across locations. In response, Geo Store standardized task definitions and introduced the R-Shift system, revolutionizing the way shifts are managed throughout all locations. This innovation has significantly improved the accuracy and speed of shift creation, allowing store managers to focus on their core management tasks.

Understanding Operational Planning and Task Assignment

Operational planning and task assignment involve determining the required tasks and their corresponding workload in advance, rather than allocating tasks based solely on who is present. Given the diverse scale and operations of its stores, accurately estimating necessary workloads and deploying staff accordingly has become an essential infrastructure for enhancing productivity across all Geo Store locations.

The Importance of a Task-Based Approach

The commitment to a task-based operational strategy is at the forefront of Geo Store's philosophy. To understand the rationale behind this approach, we consulted with the team responsible for implementing the R-Shift system.

Challenges Before R-Shift

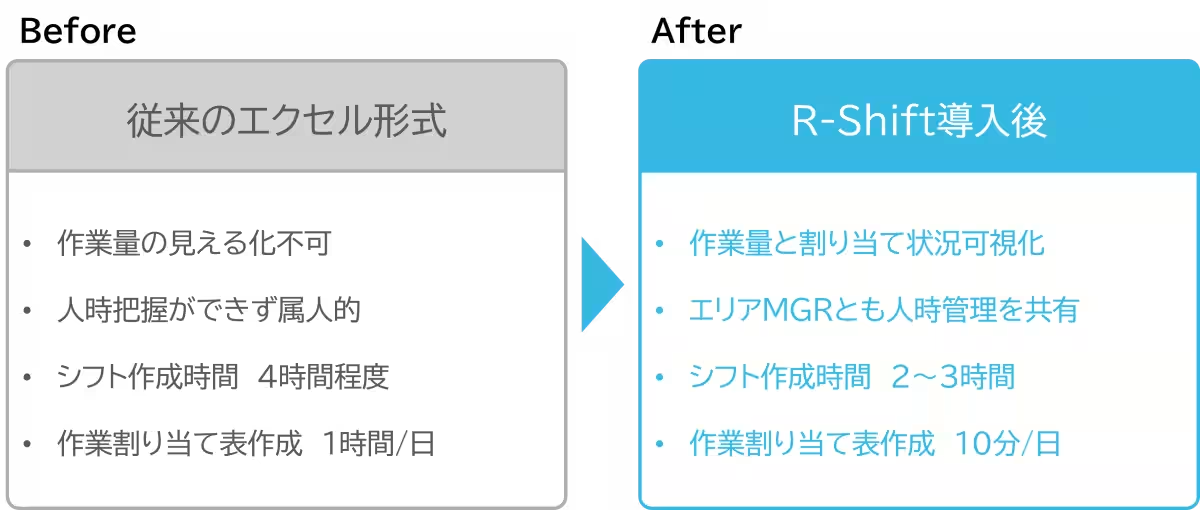

Prior to 2019, task planning and shift schedules were manually created using Excel, leading to significant time consumption each month. The challenges were compounded by the inability to aggregate data for comparison between stores or conduct area-specific analyses. Daily operations often relied on verbal instructions or manual To-Do lists, which further highlighted the need for a task assignment framework. Tests with Excel templates demonstrated a time-consuming process, where assigning tasks for 7-8 individuals could take nearly an hour, ultimately leading to a decision against deploying this method across all locations.

Transformative Changes with R-Shift

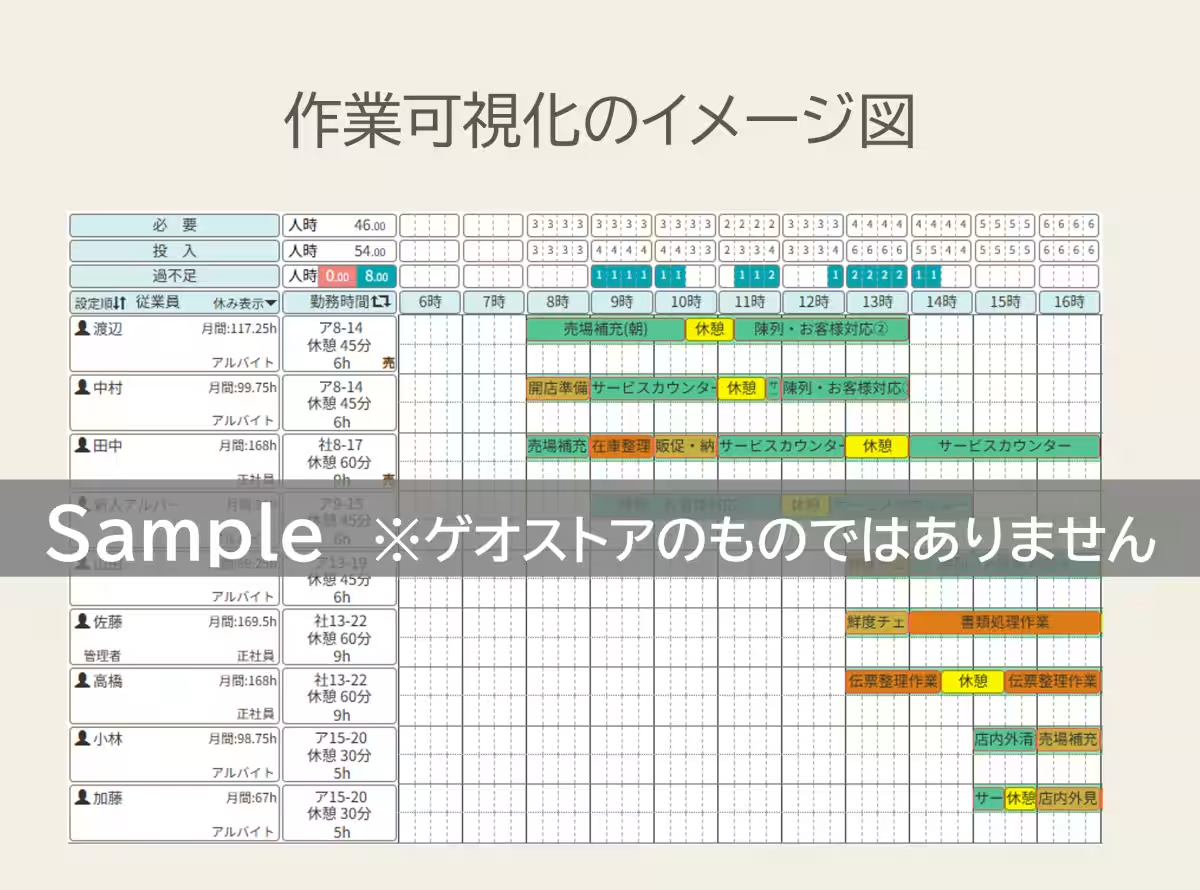

The introduction of R-Shift allowed staff to instantly know their designated tasks for the day, empowering them to work more proactively. On the management side, previously disparate methods of task planning and shift scheduling were standardized, allowing for accurate visualization of workloads and task distributions. Clear and consistent task directives issued from headquarters eliminated confusion for store managers, ensuring that essential workload assignments were properly addressed.

As a result, the burden of shift management has been dramatically lessened, enabling store managers to devote more time to essential management duties. Notably, the visibility of daily tasks assigned to individuals allows area managers to monitor operations more closely and engage in meaningful conversations with store managers.

In terms of metrics, the time required to create daily task assignments has drastically decreased from about an hour to approximately 10 minutes, while shift creation time has improved from around four hours to just 2-3 hours. This transformation is not merely about speeding up the process; it has enabled the strategic placement of personnel at necessary times based on the work requirements outlined by R-Shift.

Achieving the Ideal Framework

With concerns previously raised addressed, the foundational elements for ideal operations have been established. However, the journey to achieve this was not without its challenges. To standardize task input across differing store operations, the team established measurable benchmarks for all task categories from the onset of R-Shift’s integration. Additionally, clear definitions of what constitutes a single task were structured into manuals disseminated across locations. During the rollout, area managers received comprehensive training to ensure understanding, which was crucial for successful implementation at the store level.

Current Challenges and Future Goals

The principles established with operational planning and task assignments at Geo Store are being adapted for Second Street, a group store with distinct operational requirements. While the foundational approach of estimating work volume and appropriately allocating personnel remains consistent, heightened variability in task demand necessitates real-time assessments of workload before creating assignments. As we move forward, establishing effective operational planning for Second Street will remain a significant target.

Conclusion

Our conversation underscored Geo Group's unwavering commitment to refined operational practices. This example of steadfast adherence to established frameworks around task definition, proactive shift creation, and thorough training is relatively rare among companies in the industry today. We aim for this article to resonate with similar retail operations facing challenges in shift management. The heart of effective process implementation lies not merely in technology adoption but in creating a system that is understood and embraced at the operational level.

For more insights, please explore R-Shift’s official website, which highlights the potent capabilities of this shift management tool designed to enhance operational efficiencies.

Company Overview

Company Name: OM Network Co., Ltd.

Location: Niigata City, Niigata, Japan

CEO: Shinya Yamagishi

Business Overview: Business system development, Shift management system "R-Shift"

Website: OM Network

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.