Ultra-High Purity Hydrogen Purification Device Prototype Revealed

Ultra-High Purity Hydrogen Purification Device Prototype Revealed

In a groundbreaking development in the field of hydrogen purification, Ultra-High Purity Co., based in Oita, Japan, has introduced a prototype device known as the UHP-VASABM250101. This sophisticated piece of technology boasts a remarkable purity level of over 99.9999%, significantly exceeding the hydrogen filling standard for fuel cell vehicles, which sits at 99.97%. What sets this device apart is its incorporation of a vanadium alloy membrane, making it the first of its kind in the world, developed in partnership with Taiyo Kogyo Co. and Tokai Rika Co.

Potential Applications Across Industries

The ultra-pure hydrogen generated by the UHP-VASABM250101 has the potential to revolutionize multiple industries. In semiconductor manufacturing, where cutting-edge 2nm process rule technologies are in high demand, the ultra-high purity hydrogen is essential. Additionally, this hydrogen has critical applications in advanced medical technologies, where equipment supplying ultra-pure hydrogen gas is increasingly being integrated into operating rooms and organ preservation settings. Already, inquiries have been received from medical institutions and research facilities.

Beyond the medical and semiconductor sectors, this technology is poised to enhance the mobility industry by making hydrogen supply infrastructures for fuel cell vehicles (FCV) more compact and efficient. It could also play a crucial role in the development of high-performance and environmentally-friendly hydrogen rocket engines. Such advancements will contribute significantly to shifting various industries into a new era, fueled by clean and ultra-pure hydrogen.

Overview of the UHP-VASABM250101

The UHP-VASABM250101 is capable of producing 10 liters per minute of hydrogen at an ultra-high purity level, surpassing the required benchmarks for hydrogen fueling processes. This achievement comes from a unique combination of proprietary technology known as VASA-UHP and the VASA module for hydrogen separation, integrating the vanadium alloy membrane technology from Taiyo Kogyo and a damage detection system developed by Tokai Rika.

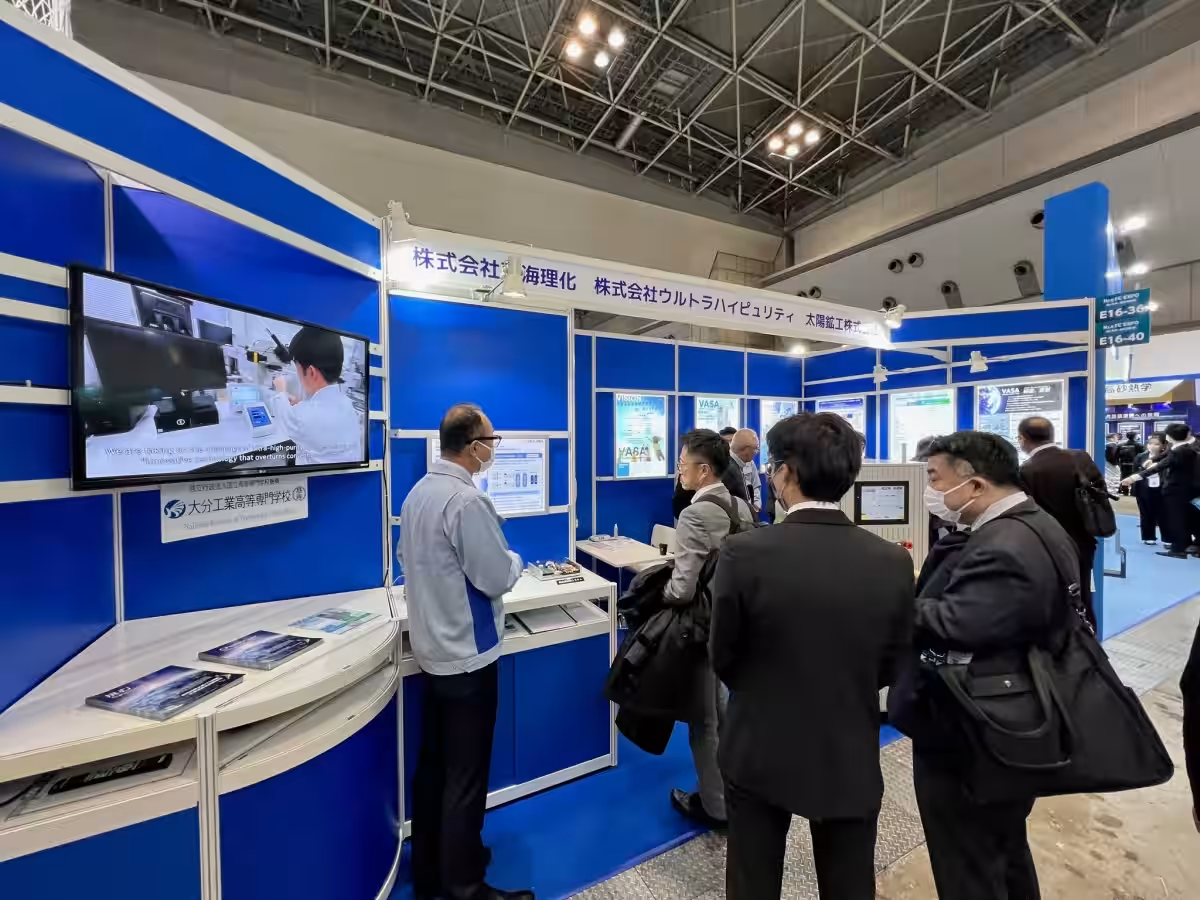

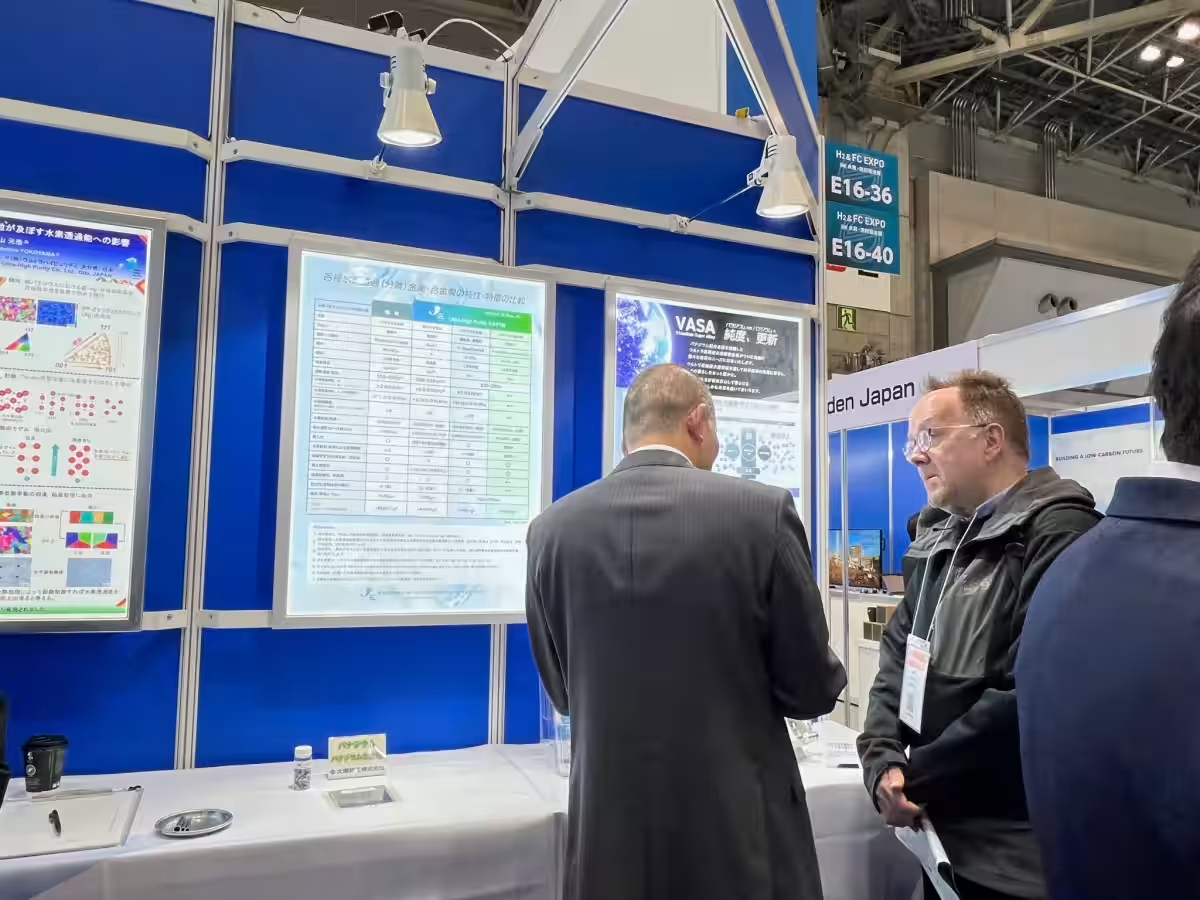

During the 20th International Hydrogen & Fuel Cell Expo (H2 & FC EXPO) held at Tokyo Big Sight in February, the prototype was unveiled, attracting over 200 representatives from global companies and research institutions keen on learning more about this innovative solution.

Technological Advantages in Cost-Effectiveness

One of the most striking advantages of the UHP-VASABM250101 lies in its vanadium alloy membrane technology, offering a significant competitive edge over traditional palladium membranes. The hydrogen permeability coefficient is over seven times higher than that of competing products. The UHP device operates at a lower temperature, achieving efficient hydrogen separation while maintaining a substantially lower material cost. Where palladium may side-line at around 2,815 yen/g, vanadium alloy costs only around 90 yen/g, utilizing an abundant resource found on Earth — a step towards building a sustainable hydrogen economy.

The proprietary hydrogen separation modules featured in the UHP-VASABM250101 are the result of years of research and development, now moving from a laboratory setting to practical application. With ongoing developments on high-pressure and large-flow systems, the device aims to meet demanding purity standards for industries requiring 8N (99.999999% purity) while also allowing for the miniaturization needed in medical applications. Furthermore, this technology promotes local production of hydrogen, subsequently reducing transportation and storage costs associated with hydrogen delivery.

Future Perspective from Ultra-High Purity Co.

As the world continues to strive for efficient renewable energy solutions, Ultra-High Purity aims to customize and collaborate on the implementation of its ultra-pure hydrogen purification technology across various industries. The company seeks to broaden its reach globally while addressing local needs, emphasizing the potential that ultra-pure hydrogen holds for businesses and research institutions eager to innovate.

Motohiro Yokoyama, the CEO of Ultra-High Purity, expressed his excitement about the transition of laboratory-level technologies into practical use. He acknowledged the contributions of Professor Yoshihisa Matsumoto from Oita National College of Technology and other faculty who have been part of this endeavor.

In conclusion, Ultra-High Purity is not merely aiming to create an efficient hydrogen purification system; it's promoting the broader vision of contributing to a clean, sustainable future for generations to come, reinforcing Japan's position on the global stage as a hub for advanced hydrogen technology.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.