SmartMat Cloud's AI Agent Reduces Inventory Costs by 13% in Just Four Months

AI-Driven Inventory Optimization: A Case Study of Success

In an era where businesses are grappling with supply management challenges, Esumat has demonstrated the effectiveness of artificial intelligence in optimizing inventory levels. Their solution, SmartMat Cloud, harnesses IoT weight sensors to monitor stock levels and utilizes an AI agent for inventory management. This innovative approach has led to significant savings for businesses, as exemplified by Maruwa Shomei, where a 13% reduction in inventory costs was achieved within just four months.

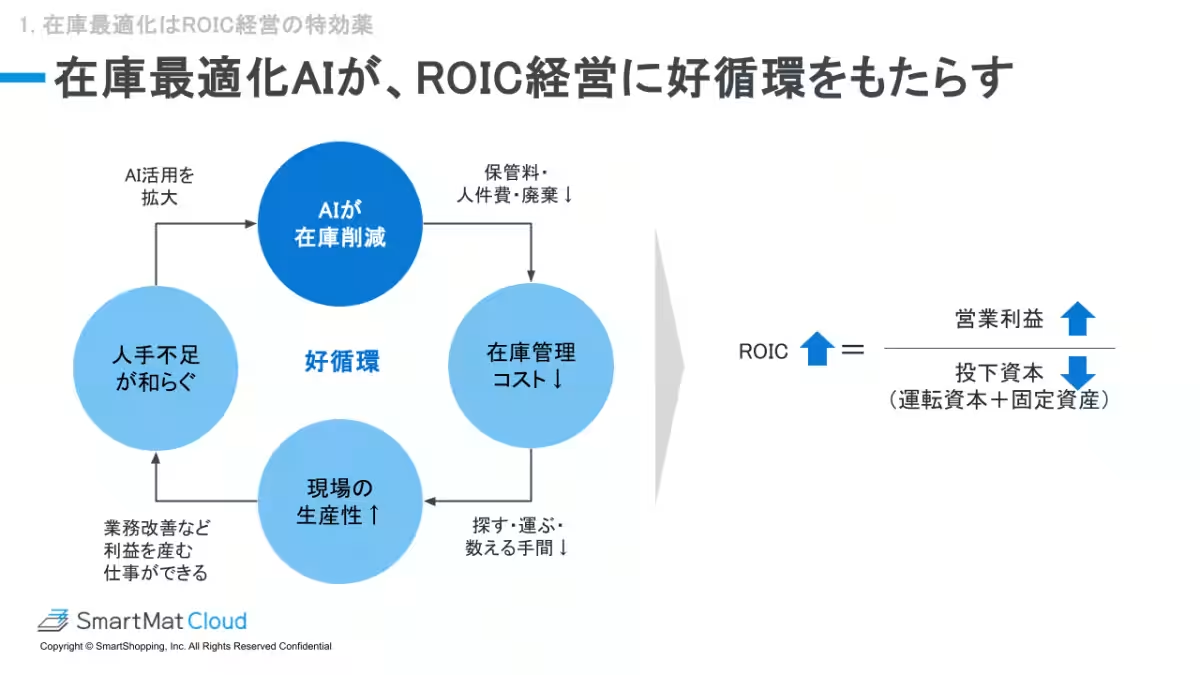

The Importance of ROIC in Inventory Management

Recent trends in corporate management highlight the significance of Return on Invested Capital (ROIC) as a metric not only for sales and profits but also for the efficient use of invested capital. Inventory plays a crucial role in this analysis:

- - Increases the operational capital, which can inflate the denominator in ROIC calculations.

- - Incurs costs associated with storage, management, and potential waste, directly impacting profit margins.

In sectors such as manufacturing, staff shortages have led to an accumulation of safety stock, resulting in an undesirable cycle where inadequate personnel leads to overstocking. Esumat believes that maintaining optimal inventory levels is a tangible way to achieve effective ROIC management.

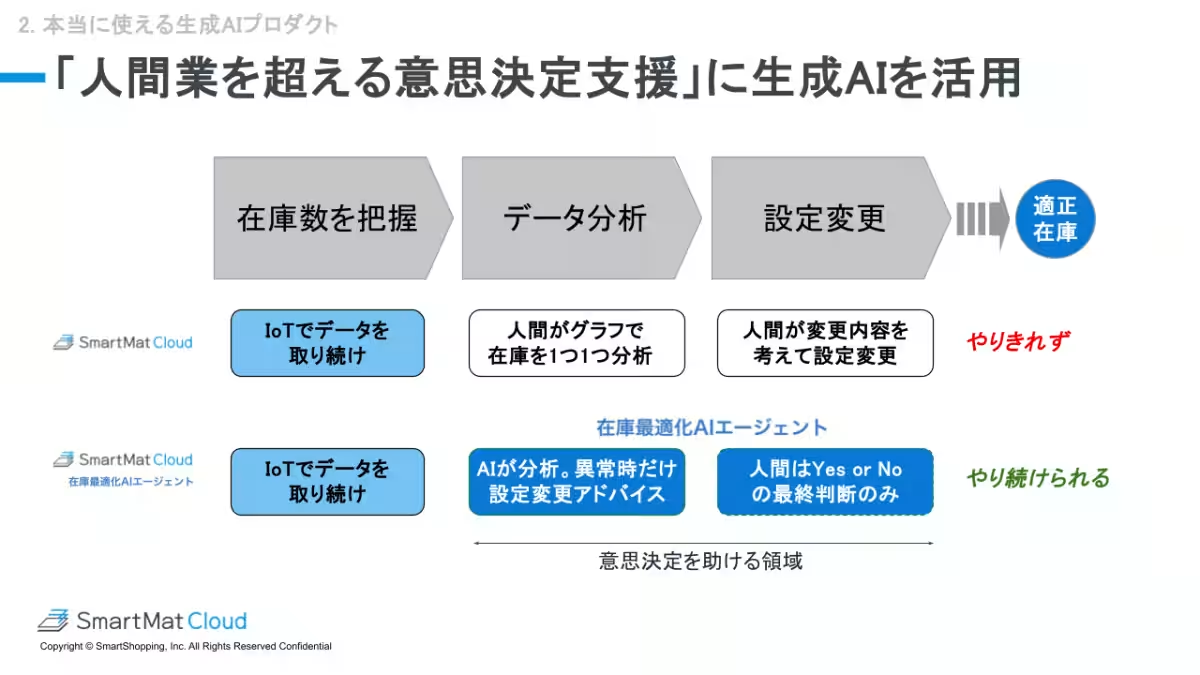

Implementing Generative AI in Real-World Applications

Despite the rise of generative AI, many companies find that functional products are scarce in operational environments. Inventory management, characterized by fluctuating consumption patterns, varying lead times, and hundreds or thousands of items, presents complex challenges. Esumat acknowledges that generative AI should be applied exactly where human decision-making is overwhelmed, which led to the creation of the Inventory Optimization AI Agent.

Case Study: Maruwa Shomei's Success

Maruwa Shomei, a company specializing in infrastructure products like road and tunnel lighting, faced challenges with maintaining adequate stock levels while avoiding excess inventory that can tie up funds. To address this issue, Maruwa Shomei implemented the SmartMat Cloud AI agent to proactively scrutinize their inventory levels.

The results were remarkable: within four months, the company managed to reduce their inventory from 23.6 million yen to 20.6 million yen, translating into a savings of 3 million yen, or 13% of their total inventory costs.

Comments from COO Tetsuhiro Morioka:

"From a management perspective, inventory is merely the physical manifestation of cash. Inadequate stock can lead to delivery delays, while excess stock locks up capital. SmartMat Cloud allowed us to gather inventory data without adding strain on our staff. The AI agent highlighted overstock, enabling us to make informed decisions for optimal inventory management. We're now more agile in identifying potential shortages, significantly reducing the pressure of delivery timelines on public contracts."

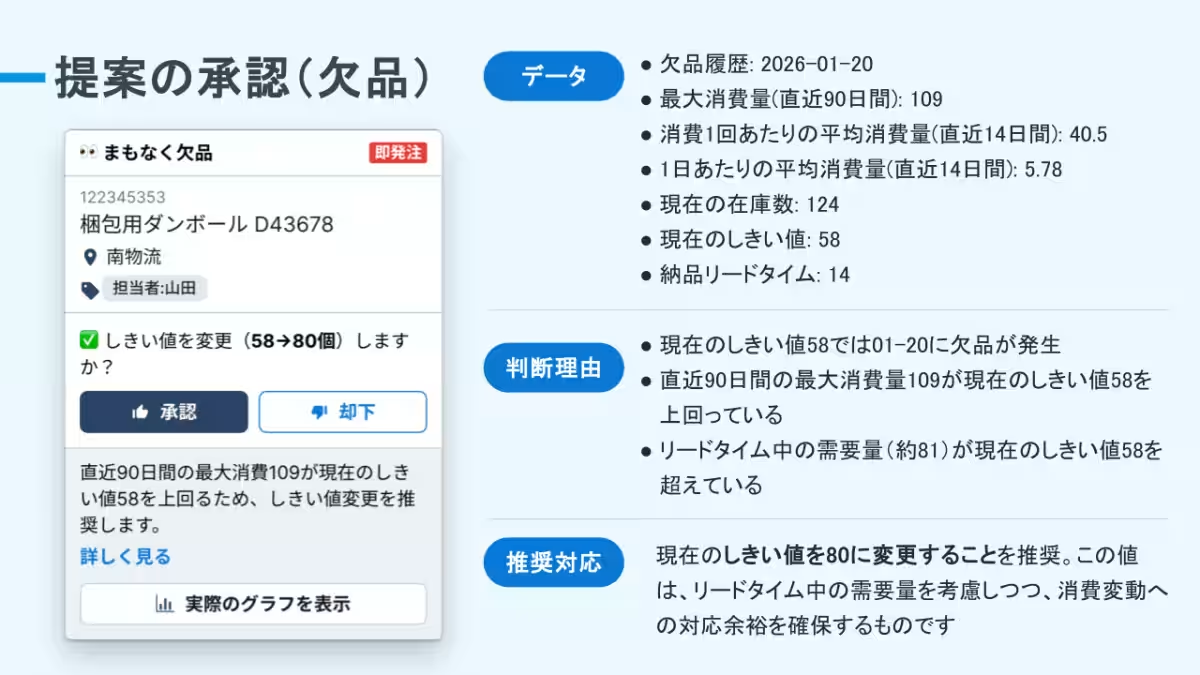

The Functionality of the Inventory Optimization AI Agent

The Inventory Optimization AI Agent moves beyond traditional AI that merely analyzes data. It leverages automatically collected inventory data from IoT weight sensors to detect signs of stock shortages or excesses sooner than human operators. Here are its main features:

- - Multi-faceted analysis of inventory data, suggesting revisions to order points and stock levels.

- - Data visualization through detailed reports and graphics to illustrate the rationale behind recommendations.

- - A human-in-the-loop system, where operators can approve or reject suggestions, enhancing the AI's learning process.

- - A streamlined operation requiring human attention only during anomalies, lightening the burden on the workforce.

This design facilitates a synergy between human expertise and AI-facilitated decision-making.

Esumat's Vision and Future Directions

Looking ahead, Esumat plans to expand functionality further by integrating order forecasts and production performance data, facilitating comprehensive demand forecasts and optimal order quantities and timing proposals. The aim is to blend human insight with AI analysis in maximizing value while minimizing resource expenditure.

Upcoming Webinars

1. Transitioning from Experience-Based Decisions to AI-Driven Inventory Management

A free webinar on Feb 26, 2026, showcasing how Maruwa Shomei reduced inventory by 3 million yen using SmartMat Cloud.

2. Lunch & Learn with Esumat

Join Esumat on Feb 12 & 26, 2026, for online sessions detailing their operations and future vision. Both webinars will dive into effective inventory automation and the role of AI in operational excellence.

Conclusion

In conclusion, the success of SmartMat Cloud and the deployment of the AI agent at Maruwa Shomei represent a pivotal moment for inventory management practices in today's business landscape. As companies face mounting pressure to optimize resources and manage inventory costs effectively, solutions like Esumat's are proving to be invaluable tools for success. By balancing human acumen with advanced AI functionalities, organizations can navigate the complexities within their supply chains, ultimately maximizing their operational efficiency and resilience.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.