Automated Drone Inspection Technology for Underground Infrastructure Takes Shape

Automated Drone Inspection for Underground Infrastructure

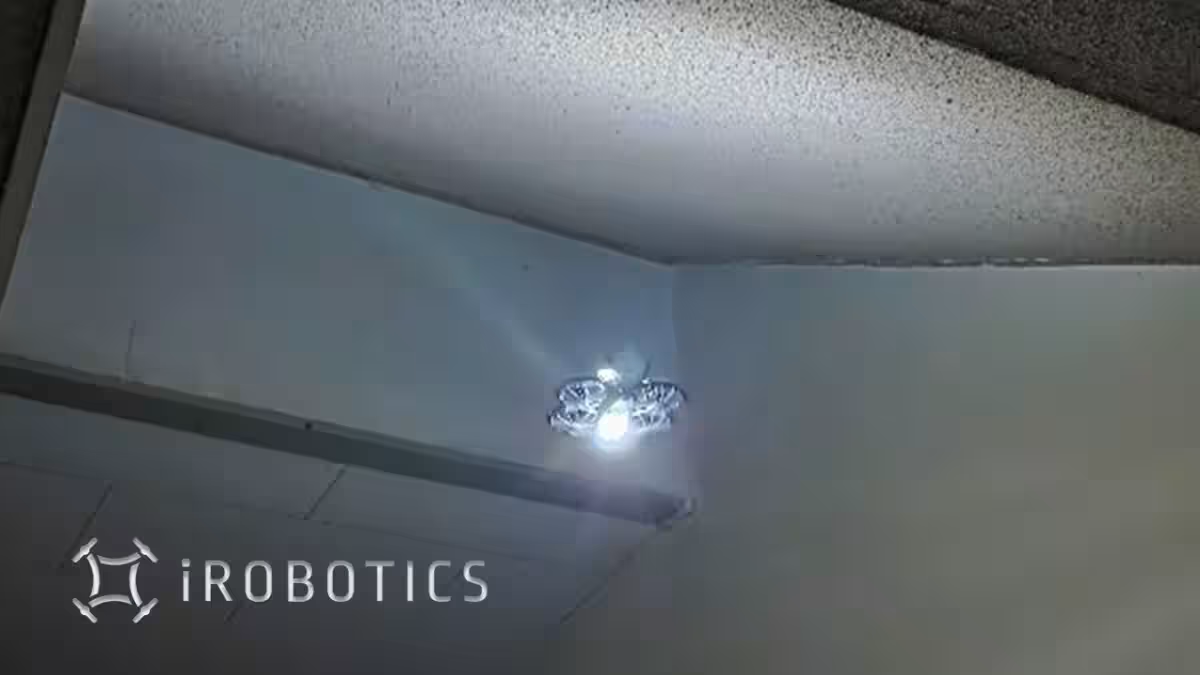

The Japanese company, iRobotics, headquartered in Chiyoda, Tokyo, is making significant strides in the realm of drone-based inspection technology aimed at the underground infrastructure. By leveraging their expertise in 360° drone inspection and automated processes, they have conducted verifiable technology tests to fully automate inspection tasks for underground facilities and confined spaces.

Simplifying Data Acquisition

The team has eliminated the need for expensive specialized equipment, instead opting for commercially available drones. This innovative approach significantly reduces the cost of data acquisition while making the process straightforward and feasible for end-users. The focus is on providing a practical means of visualizing space data to facilitate a transition to fully automated inspection workflows for underground infrastructures.

Establishing Screening Methods

In pursuit of a future where drones autonomously inspect underground facilities, iRobotics understands that immediate full automation of flights is unrealistic. Hence, an initial phase involves data collection through manual screening processes. This phase aims to gather comprehensive information about the spatial structure, equipment layout, and potential obstacles within these environments.

The gathered spatial data will pave the way for validating control logics and route designs needed for future automation, making it imperative for this initial phase to be executed in a simplistic and adaptable manner across various underground environments.

Structural Challenges Within Underground Facilities

Traditionally, inspection tasks for underground infrastructure have relied heavily on seasoned technicians’ expertise and judgment. Heavy dependence on tacit knowledge has led to significant challenges, including a lack of systematic organization and accumulation of inspection results and judgment processes. Many records are fragmentary and inadequately structured for future comparisons or automated applications.

While drone inspections are becoming increasingly prominent, the introduction of equipment alone is not sufficient to ensure future automation. Without clearly defined criteria for judgment, inspection items, and information granularity, achieving the necessary reproducibility and interpretability of inspection results remains a challenge, which risks pigeonholing these technologies as mere replacements for conventional inspections.

General Process without Specific Requirements

By utilizing Antigravity A1, which is equipped with a 360° camera capable of capturing hemispherical data, iRobotics is ensuring that both ceilings and floor equipment can be recorded in a single flight. This drone boasts the ability to record at 8K resolutions, leading to comprehensive spatial understanding. Additionally, it is user-friendly, allowing non-specialist operators to manage flights effectively, thus keeping costs low.

In parallel, the DJI Neo2 drone presents advanced collision avoidance features, making it suitable for narrow underground spaces. Its stable self-positioning capability allows for consistent 4K video data acquisition, which provides crucial insights for future route design and safety margin evaluations.

Capturing Usable Data from Real Environments

The practical implications of these test environments emphasize the importance of real-world feasibility when it comes to verification. Findings from iRobotics showcase:

- - Stable flight operations in densely packed environments.

- - Adequate resolution and visibility of acquired images and videos for inspection and exploration tasks.

- - Achievement of detailed, expert-level data necessary for preliminary screening processes.

These data sets evolve beyond mere records, serving as foundational information for automated route designs and safety assessments.

Supporting Facility Management Automation

iRobotics aims to aid facility managers with the insights gained from this demonstration. They offer a service streamlining automation and digital asset integration—improving operational efficiency while reducing downtime requirements for repairs.

The company emphasizes flexible integration of tested technologies into inspection processes rather than adhering strictly to costly, specialized gear, thereby reinforcing an adaptable infrastructure that can keep pace with future developments.

Conclusion: Transforming Inspections into Data Generation Activities

Japan faces a structural challenge concerning labor shortages, particularly among experienced technicians, necessitating the evolution of inspection processes. Instead of routine operations, inspections must transform into activities that generate valuable data, paving the way for future developments in automation and enhanced inspections through specialized drone needs.

With these objectives in mind, iRobotics seeks to establish a standard model for inspections that successfully bridges the gap between cost-effective solutions and complex, high-level projects. This pioneering approach will not only improve the abilities of existing technologies but support the overall progression of domestic technical innovations in inspections.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.