Innovative Continuous Flow Synthesis of Parkinson's Drug Enhances Production Efficiency and Reduces Waste

Innovative Continuous Flow Synthesis of Parkinson's Drug Safinamide Mesylate

In a remarkable advancement for the pharmaceutical industry, researchers at AIST have developed an innovative continuous flow synthesis process for Safinamide Mesylate, a critical medication for treating Parkinson's disease. This new technique not only enhances production efficiency but also significantly reduces waste, marking a substantial leap towards sustainable pharmaceutical manufacturing.

The Breakthrough Process

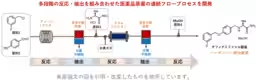

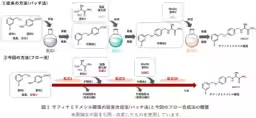

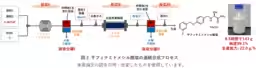

Backed by AIST's Catalysis Chemistry Research Group, led by Takahiro Kobayashi and Yasu Yada, this groundbreaking method combines multi-step continuous reactions with extraction operations. The traditional batch processing used for synthesizing Safinamide Mesylate involves isolating and purifying intermediates at each reaction stage, leading to a lengthy and wasteful manufacturing process. However, the newly developed continuous flow process elegantly circumvents these challenges, enabling the rapid and efficient synthesis of the drug.

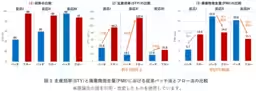

By applying this new method, production efficiency has improved by an impressive 3.4 times compared to conventional techniques, while also reducing waste generation by 20%. These results underscore the method's potential to enhance productivity and decrease environmental impact in pharmaceutical manufacturing.

Context and Significance

As global populations age, the incidence of neurodegenerative disorders like Parkinson's disease is rising dramatically. In Japan alone, it is estimated that around 200,000 individuals are affected. In this context, Safinamide Mesylate, marketed under the brand name

Topics Health)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.