Revitalizing Heritage: Numata Kouki's Sapphire Glass Innovation and Sustainable Badge

Numata Kouki: Pioneering Sapphire Glass Technology

Introduction to Numata Kouki

Based in the Adachi ward of Tokyo, Numata Kouki Co., Ltd. is a distinguished manufacturer renowned for its expert polishing techniques in sapphire glass, which is second in hardness only to diamond. The company specializes in producing cover glass primarily for luxury watches, making it one of the few leaders in this niche sector in Japan. In recent years, facing challenges from cheaper overseas production, Numata Kouki has focused on branding its unique strengths and innovating sustainably.

The Fascinating World of Sapphire Glass

Sapphire glass, composed of synthetic sapphire, is celebrated for its clarity, resistance to scratching, and durability under high temperatures, making it the perfect choice for high-end watch covers. However, its hardness also makes it difficult to process, requiring advanced polishing techniques that only a handful of Japanese companies possess, including Numata Kouki.

With two production facilities in Adachi, the firm does not just focus on watch covers; it also processes sapphire glass for high-brightness LED boards and various inspection jigs.

A Historical Journey

Founded in 1960 by Yoshitoku Shimokawa, the company initially specialized in the polishing of inorganic glass, producing optical lenses for binoculars and telescopes for leading Japanese optical manufacturers. Numata Kouki began its venture into the processing of inorganic glass for watch covering in 1964, which remained its mainstay until around 2000.

Adapting to Challenges

The early 2000s brought significant shifts in the industry, as major watch manufacturers began outsourcing component production to cost-effective regions like China. Under these circumstances, President Takayuki Shimokawa remembers how contract renewals suddenly disappeared:

“I remember being summoned by a long-term client who suddenly announced, ‘Your contract will end in six months.’ We were polishing glass for about 150 yen per piece, whereas in China, it was below 30 yen. We couldn’t compete.”

Amidst these struggles, Takayuki, who had joined the company in 1995, embarked on efforts to retain business by launching a website and reaching out for alternate clients, but impacts were minimal. With shrinking jobs, he and his father faced dire choices; opting for a transition to sapphire glass processing seemed vital.

Resilience and Skill Development

To gain expertise in sapphire glass processing, Takayuki received training from a partnered company in Saitama, spending four months learning while simultaneously shifting the company’s focus to this new domain. Initially, only five pieces were polished daily, but through perseverance, production ramped up to around 100 pieces within 18 months, marking a significant turnaround in their fortunes.

Expanding Horizons: Swiss Collaborations

Subsequently, Numata Kouki secured contracts to polish sapphire glass for Swiss brands, a transformation that increased their monthly output to approximately 8,000 pieces. However, obstacles arose again in 2007 when the Swiss Watch Association enforced stricter rules regarding the ‘Swiss Made’ label, further threatening Numata's business.

In response, Takayuki invested in a professional website overhaul, which became the turning point for the business, leading to a new major partnership with another prominent watch manufacturer that had faced sudden production issues.

Recognition and New Opportunities

During this evolving landscape, Numata Kouki applied for the ‘Adachi Brand’ certification and received recognition two years into the program. This accolade improved their reputation in the industry, enhancing trust and opening doors for new business opportunities. The certification allowed the company to showcase its excellence boldly while diversifying growth avenues

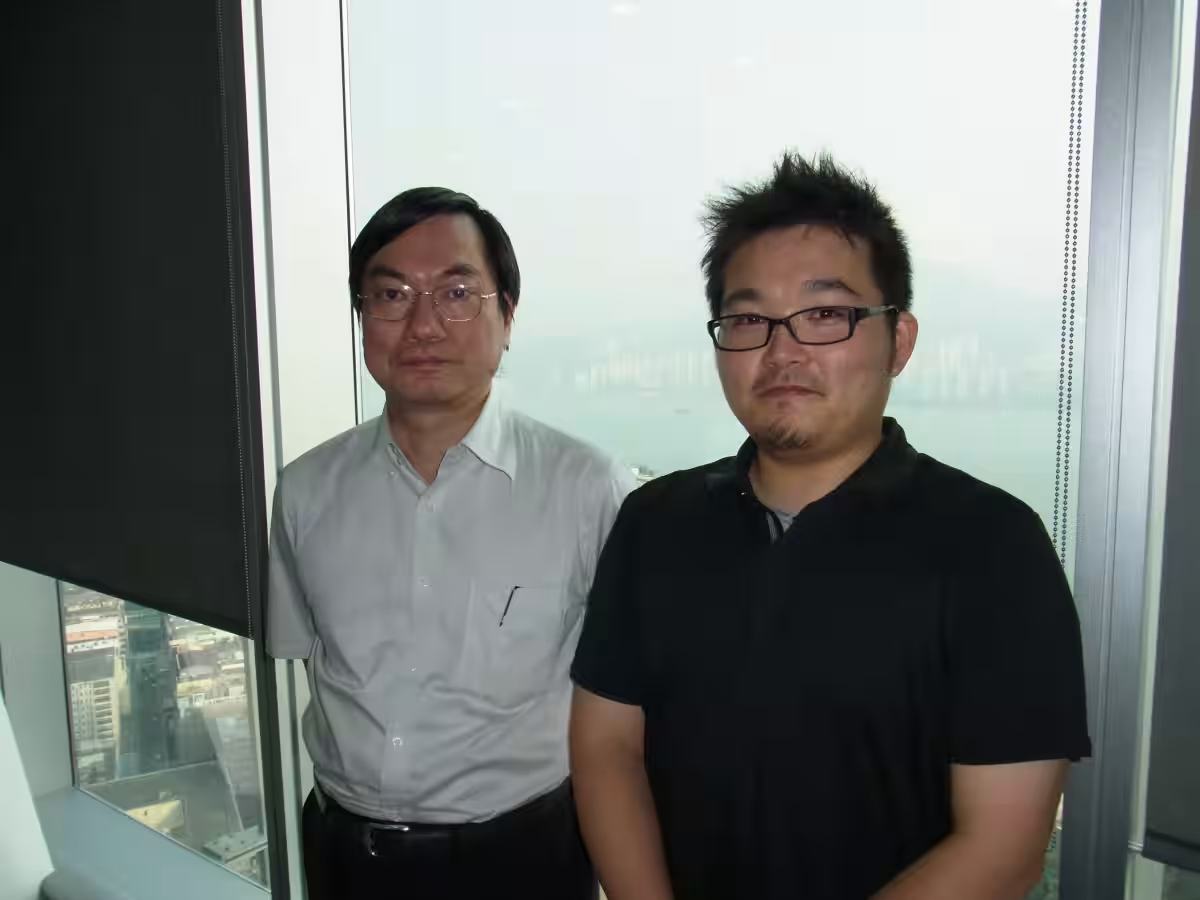

Global Expansion: Hong Kong Branch

In 2009, the establishment of Numata Kouki HK marked a strategic shift toward coexisting with Chinese manufacturers, where it began sourcing high-quality products from China for Japanese watch makers, focusing on ensuring quality control in their shipments. As a result, they’ve established significant business relationships with Japan’s leading three watch manufacturers.

Developing a Distinct Brand Identity

In a pivotal cultural shift within the company, Takayuki announced plans to transform from a behind-the-scenes supplier to a brand recognized for its craftsmanship. With declining sales in the overall watch industry, he stressed the importance of carving out a unique market space where few sapphire processing firms exist. The firm plans to venture beyond watch components into developing sapphire-based parts for cosmetics and civil safety equipment, massively broadening their market scope.

Empowering Employees in Innovation

In an exciting initiative, all employees are encouraged to propose product development ideas with a budget allocated for experimentation. This led to the development of a corporate badge using leftover sapphire glass, embedding sustainable practices into their operations while gaining positive feedback from clients and partners, with orders commencing this spring.

Takayuki welcomes his son into the company, encouraging him to use social media for brand presence, and is hopeful that his legacy will continue to adapt and thrive amid evolving market trends.

Closing Thoughts

As Numata Kouki repositions itself to forefront its reputation and innovative capabilities while maintaining its long-standing heritage, the company stands as a remarkable example of resilience, creativity, and sustainable growth in the competitive landscape of sapphire glass manufacturing.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.