Strengthening Quality Management Systems in Pharmaceutical Companies with GMP Updates

Enhancing GMP Practices for Pharmaceutical Quality Management

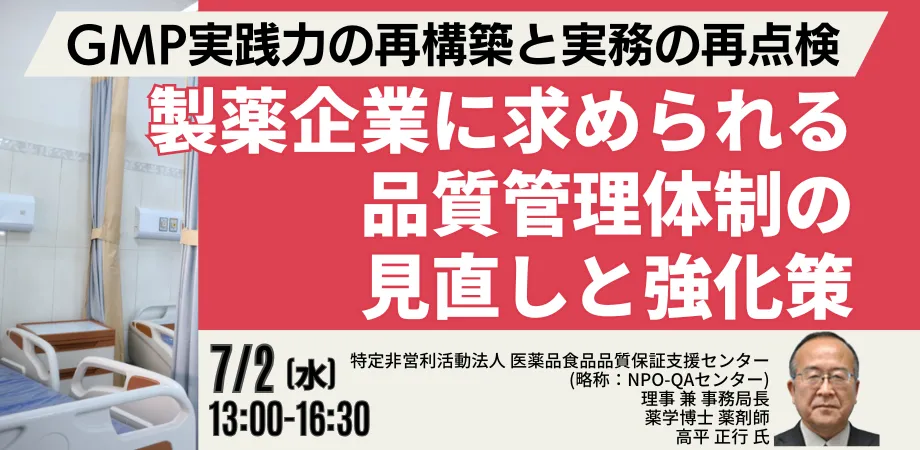

On July 2, 2025, a crucial seminar titled "Reconstructing GMP Practices and Reevaluating Practical Operations: Revisiting and Strengthening Quality Management Systems Required by Pharmaceutical Companies" will be hosted by the Japan Planning Institute (JPI). The seminar is specifically designed for professionals in the pharmaceutical industry who are navigating the ever-evolving landscape of Good Manufacturing Practices (GMP).

The event will feature Dr. Masayuki Takahira, a pharmacist and executive director of the non-profit Pharmaceutical and Food Quality Assurance Support Center, as the primary speaker. His extensive knowledge and insight into GMP dynamics are anticipated to provide valuable takeaways for attendees.

Background and Purpose

GMP regulations have been in place since 1963, established to prevent tragic incidents related to pharmaceuticals. With advances from the 1980s through the 2000s, including the introduction of global GMP regulations such as PIC/S and ICH Q8-13, Japan modified its GMP regulations in August 2021. However, despite these advancements, issues such as counterfeit medications and product defects continue to plague the industry worldwide.

The seminar aims to equip attendees with the knowledge to elevate their practice of GMP beyond mere compliance. Participants will learn about the standardization of pharmaceutical quality, the automation of production and QC processes, and strategies for leveraging digital transformation (DX) to improve GMP execution. The emphasis will be on ensuring that the push for productivity does not compromise the essential quality assurance of pharmaceuticals.

Seminar Overview

Key topics to be covered during the seminar include:

1. Introduction

- The evolving landscape surrounding pharmaceutical GMP, including globalization and ICH developments.

- Background on amendments to the Pharmaceutical and Medical Device Act and GMP regulations.

- A shift in the quality paradigm observed over the past two decades, analyzing whether increased productivity is tipping the balance away from quality assurance.

2. Evaluation of New Procedures Under Revised GMP Regulations

- Implementation and adherence to the ICH Q10 guidelines concerning pharmaceutical quality systems.

- Insights from recent updates to GMP notifications, focusing on compliance infrastructure and documentation integrity.

- Establishing robust QA departments and enhancing communication between manufacturers and distributors.

3. Learning from Previous GMP Violations

- Analyzing case studies on compliance failures and what can be gleaned from audits and self-inspections to prevent recurrence.

4. Expanding GMP Implementation Capacity

- Identifying key performance indicators for enhancing GMP effectiveness based on labor trends over the past years.

- Exploring strategies for deepening knowledge management and cultivating a quality culture within organizations.

5. Conclusion

- Final thoughts, followed by a Q&A session where attendees can engage directly with Dr. Takahira for personalized inquiries.

Registration and Participation

The seminar will be conducted online, with options for live streaming or accessing the recorded session for up to two weeks post-event. The participation fee is 40,000 yen (tax included) for a single attendee, with a discounted rate of 35,000 yen per person for groups from the same company.

For more details or to register, interested individuals can visit JPI's seminar page. This seminar not only aims to reinforce vital GMP practices but also fosters networking opportunities among participants and may pave the way for new business ventures within the pharmaceutical sector.

Company Information

The Japan Planning Institute, located at 5-2-32 Minamiazabu, Minato-ku, Tokyo, has been facilitating knowledge-sharing seminars aimed at promoting national policy initiatives for over 50 years. Their commitment to bridging knowledge among public and private sectors continues to benefit professionals throughout the industry.

If you seek to enhance your understanding of GMP practices and ensure product quality in your organization, this seminar is an unmissable opportunity.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.