Seven-Eleven Japan Implements Sustainable Supply Chain Initiatives

Seven-Eleven Japan's Sustainable Initiatives

In response to changing social environments such as population decline and aging, Seven-Eleven Japan, headquartered in Chiyoda, Tokyo, is pioneering efforts to build a sustainable supply chain. Starting February 9, the company is set to reduce the manufacturing frequency of key products in the Hokkaido area as part of its efficiency enhancement strategy.

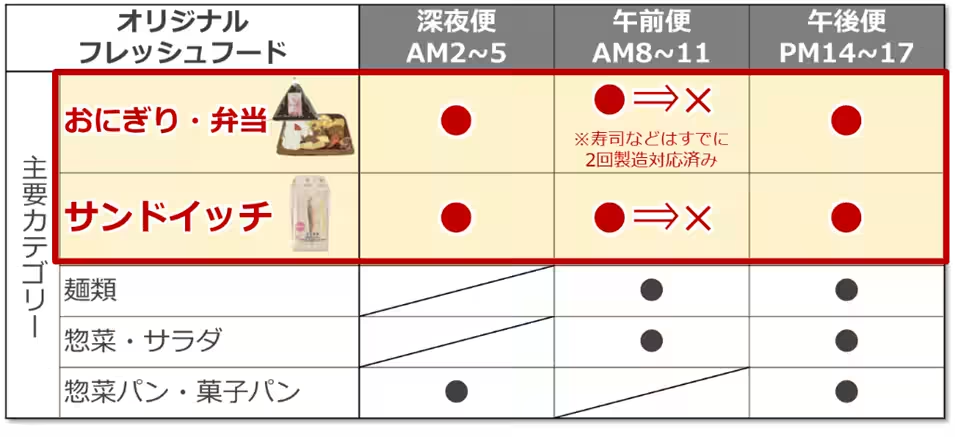

This initiative will lower the production frequency of approximately 60 popular fresh food items, including rice balls, bento boxes, and sandwiches, from three times a day to just twice a day. As a result, all original fresh food offerings in Hokkaido will now be manufactured twice or less daily. The shift is significantly influenced by the application of new technologies developed through collaborative partnerships with educational institutions, allowing for better identification of harmful bacteria and contamination pathways, which in turn enhances hygiene levels during production. This meticulous control enables a sustained freshness while reducing the overall manufacturing frequency.

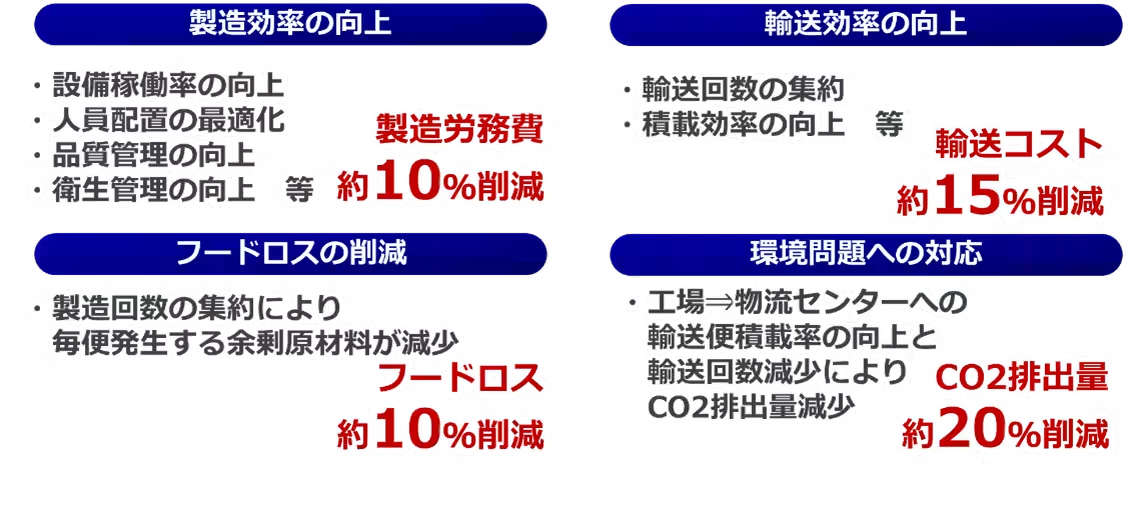

The challenges faced in the Hokkaido area, including low manufacturing efficiency, long-distance transportation issues, and employment concerns in production facilities, spurred this innovative endeavor—making Seven-Eleven Japan a trailblazer in the region. The anticipated benefits include improvements in manufacturing efficiency, enhanced transportation logistics, reduction of food waste, and a decrease in CO2 emissions.

Previously, the company has also engaged in various initiatives to tackle evolving environmental and societal issues, such as reducing delivery frequencies and extending lead times. Seven-Eleven Japan is committed to continuously addressing logistical challenges to further enhance their supply chain resilience.

Details on the Reduction of Manufacturing Frequency

The focus of this initiative is on transitioning the production cycle of specific categories from three times a day to two. This involves continuous nighttime and afternoon production runs. It is important to note that while manufacturing frequency is reduced, there will be no changes to the total delivery frequency to stores.

Targeted Items

The initiative will encompass rice-based items like rice balls and bento, as well as prepared breads like sandwiches, totaling approximately 60 distinct items.

Expected Outcomes

Preliminary estimates suggest significant theoretical benefits from the new production schedule, emphasizing sustainable practices.

Previous Efforts by Seven-Eleven Japan

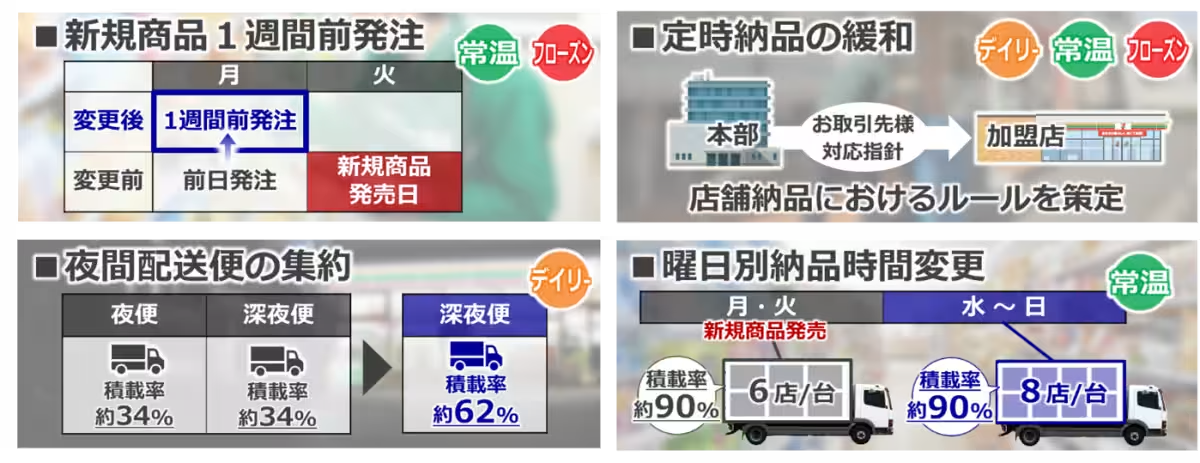

- - Pre-Order for New Products: By adjusting the order date for new products, the company allows for stock optimization a week ahead, better balancing regional inventories.

- - Relaxation of Scheduled Deliveries: New delivery policies implemented in 2023 facilitate flexible delivery times, reducing waiting periods at stores and the time drivers are on duty.

- - Nighttime Delivery Consolidation: Currently applied in about 9,500 stores, the consolidation of night deliveries for perishable goods like rice balls and sandwiches enhances load rates and reduces driver work hours.

- - Revised Delivery Timings: Some 11,300 stores have altered delivery schedules on specific days tailored to anticipated new product releases, improving logistical efficiency based on demand fluctuations.

As these initiatives unfold, Seven-Eleven Japan's dedication to sustainability and supply chain optimization remains steadfast, paving the way for future innovations.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.