Reducing Environmental Impact with Innovative Shotcrete Solutions

Reducing Environmental Impact with Innovative Shotcrete Solutions

In a significant move towards sustainable construction, Tekken Construction Co., Ltd., based in Chiyoda, Tokyo, has successfully implemented shotcrete using blast-furnace cement type B in a tunnel construction project commissioned by East Japan Railway Company. This innovative approach not only meets the rigorous demands of the cold mountainous environments but also dramatically reduces CO2 emissions during the production process.

Background

Historically, Tekken Construction has experimented with blast-furnace cement type B in shotcrete applications primarily in relatively warm regions, achieving commendable reductions in carbon emissions. Nonetheless, concerns arose regarding the initial strength of this cement type when applied in colder climates, prompting the company to validate its feasibility in cold mountain tunnel applications.

Practicality and Workability in Cold Conditions

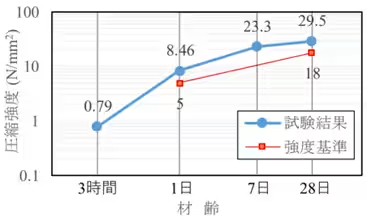

In preparation for this venture, the team first established a target strength based on the Ministry of Land, Infrastructure, Transport and Tourism's specifications for shotcrete, aiming for a design compressive strength of 18N/mm² at 28 days of age. By meticulously selecting materials—including blast-furnace cement type B, fine aggregates, coarse aggregates, and a high-performance water reducer—the team conducted trials under controlled indoor conditions. This led to the identification of an optimal mixture exhibiting excellent fresh-state properties.

Following this, powdered quick-setting agents were included into the mortar, minus the coarse aggregates, to evaluate quick-setting characteristics and strength emergence. The results indicated that while mixing at a temperature of 20°C, the quick-setting capabilities were on par with traditional Portland cement shotcrete, and the strength development and compressive strength exceeded the predetermined benchmarks.

Test Results

During the actual site application, the average daily temperature hovered around 4°C, with minimum temperatures dipping to -4°C. These challenging conditions necessitated careful management at the site’s batching plant, where mixing water and aggregates were heated to ensure the concrete mix departing from the plant exceeded 20°C. The shotcrete application mirrored the use of traditional Portland cement, displaying excellent adhesion and minimal rebound, which confirmed robust workability during placement.

The compressive strength tests yielded an average strength of 5.36N/mm² at one day and 26.0N/mm² at 28 days, affirming that the shotcrete developed with blast-furnace cement type B is entirely viable for use in cold regions, meeting all strength criteria.

Future Prospects

By simply switching from standard Portland cement to blast-furnace cement type B, Tekken Construction anticipates reducing CO2 emissions by 114.5 kg per cubic meter of shotcrete based on a standard unit cement quantity of 360 kg/m³. In the current tunnel application, with an extension of 138 meters and a cross-sectional area of 75.1 m², approximately 260 tons of CO2 emissions have been successfully mitigated.

Tekken Construction is committed to further innovations in shotcrete technology aimed at decarbonization, continuing our efforts to reduce CO2 emissions further in all future projects. This groundbreaking application of eco-friendly materials not only benefits the environment but also sets a new standard in the construction industry by demonstrating that sustainability and performance can indeed go hand in hand.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.