Innovative 3D Shaping Method Using Short Carbon Fibers Developed by Okayama University

Innovative 3D Shaping Method Using Short Carbon Fibers

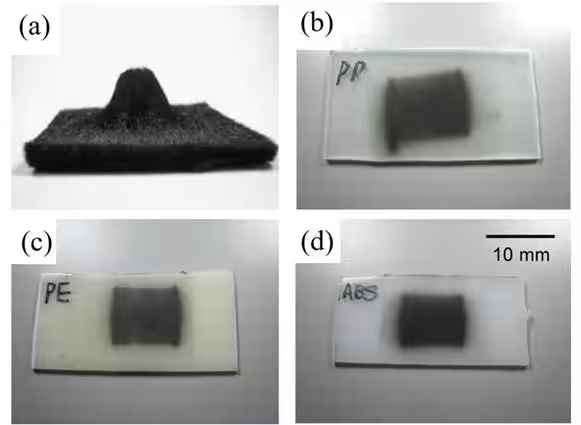

Okayama University, in collaboration with Ryukoku University, has made a significant breakthrough in material science with the development of a novel 3D shaping technique utilizing short carbon fibers, measuring less than 0.2 mm in length. This groundbreaking method allows for the rapid construction of three-dimensional structures through a novel approach known as Fiber Aerosol Deposition (FAD), completely eliminating the need for adhesives.

Research Highlights

Recent findings reveal that the shaping mechanism of this process is primarily driven by the frictional entanglement of the fibers themselves. This innovative process stands out as the first of its kind in the world, marking a substantial advancement over traditional 3D printing technologies. Notably, the method achieves an impressive vertical growth rate of up to 0.3 mm per second, outpacing conventional techniques significantly.

The research team, which includes Assistant Professor Hongwu Yu, Professor Naoshi Ikeda, and several experts from both universities and various research institutions, has contributed to this international collaboration. This research, published in the journal Materials & Design, highlights the potential for recycling carbon fibers and efficiently utilizing various short fiber materials to enhance the production of diverse applications, such as water treatment filters and next-generation electrode materials.

Insights from the Researchers

According to Professor Ikeda, the team serendipitously stumbled upon this phenomenon, which has paved the way for new technologies. He expresses optimism that similar formations can be achieved using any short fiber materials, suggesting a future where entirely new objects may be created using this technique.

Unique Structural Properties

The FAD method allows researchers to inspect and observe the unique hierarchical structure it creates. Scanning electron microscopy and X-ray computed tomography examinations have unveiled that within the formed structures, longer fibers align vertically near the surface, while shorter fibers densely fill the interior randomly. This results in a robust structure that does not require binding agents, thereby achieving heightened mechanical strength.

The implications of such a technique extend well beyond academia, as it holds promises for various industries willing to explore advanced composite materials. The findings suggest that this approach not only opens doors to the creation of new functional materials but also plays a significant role in promoting sustainability through efficient material use.

Future Directions

As researchers continue to navigate the various aspects and applications of this technology, exciting developments can be anticipated. The potential applications of this method are extensive, and further exploration may yield innovative products that could transform sectors reliant on advanced materials, such as technology, manufacturing, and environmental management.

The original findings and the comprehensive research details can be accessed via Materials & Design.

This remarkable achievement by Okayama University and its partners is a testament to the power of collaboration and innovation in academia, urging other institutions and industries to harness similar synergies for future advancements.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.