Introducing ARBURG Freeformer: Revolutionizing 3D Printing with Direct Pellet Processing

The New Wave of 3D Printing: ARBURG Freeformer

In a game-changing development for the 3D printing industry, Japan 3D Printer Co., Ltd. has announced its partnership with the renowned German manufacturer ARBURG to introduce the Freeformer series. This innovative line of 3D printers allows for direct manufacturing of high-functioning components using injection molding pellets, eliminating the need for expensive specialized filaments.

Origin and Expertise of ARBURG

Founded in 1923 in Lossburg, Germany, ARBURG has over a century of expertise in producing high-quality injection molding machines. With 36 branches across 26 countries and a workforce of 3,700, ARBURG stands as a leader in the global injection molding market. The Freeformer series is the culmination of ARBURG's knowledge in thermoplastic materials and advanced injection molding technology, designed to cater to a diverse range of industries demanding precision and performance.

Groundbreaking Technology: The ARBURG Freeformer

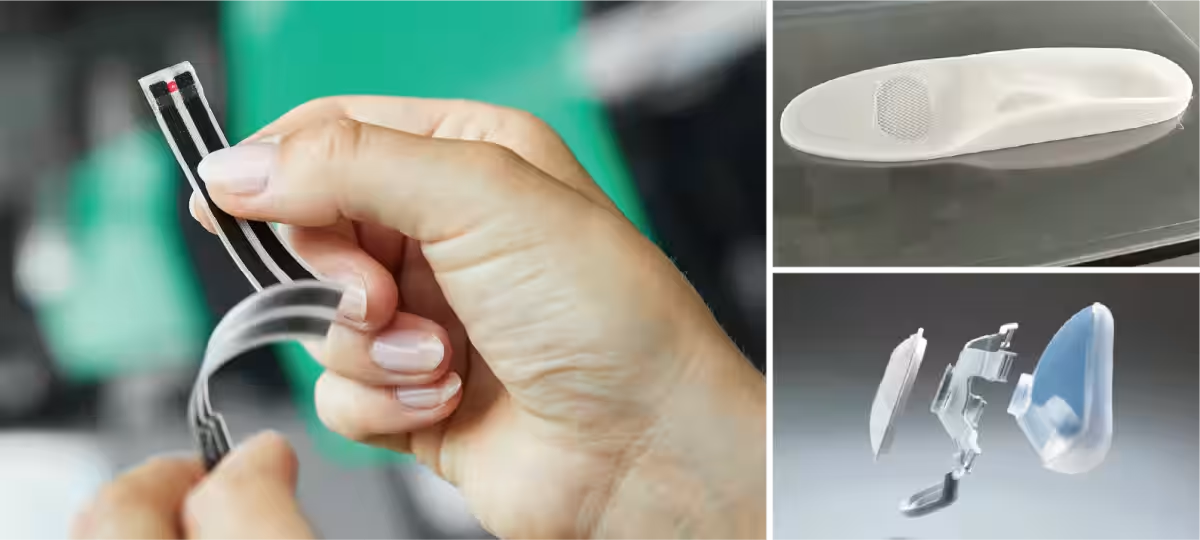

The ARBURG Freeformer excels in utilizing common injection molding pellets, a move that not only cuts costs but also provides flexibility in material selection. The printer is capable of multi-material construction using up to three screw units, catering to stringent requirements in sectors such as medical and aerospace engineering.

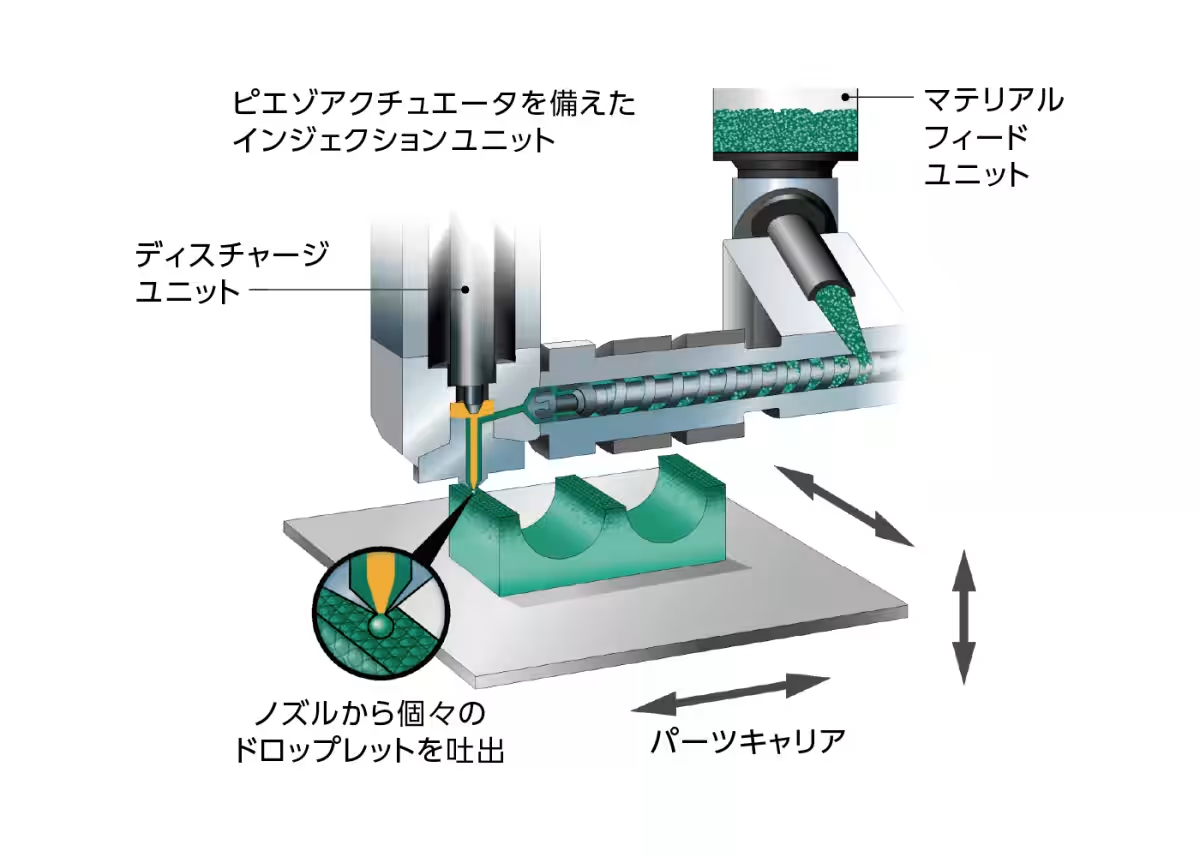

Unique AFP Technology

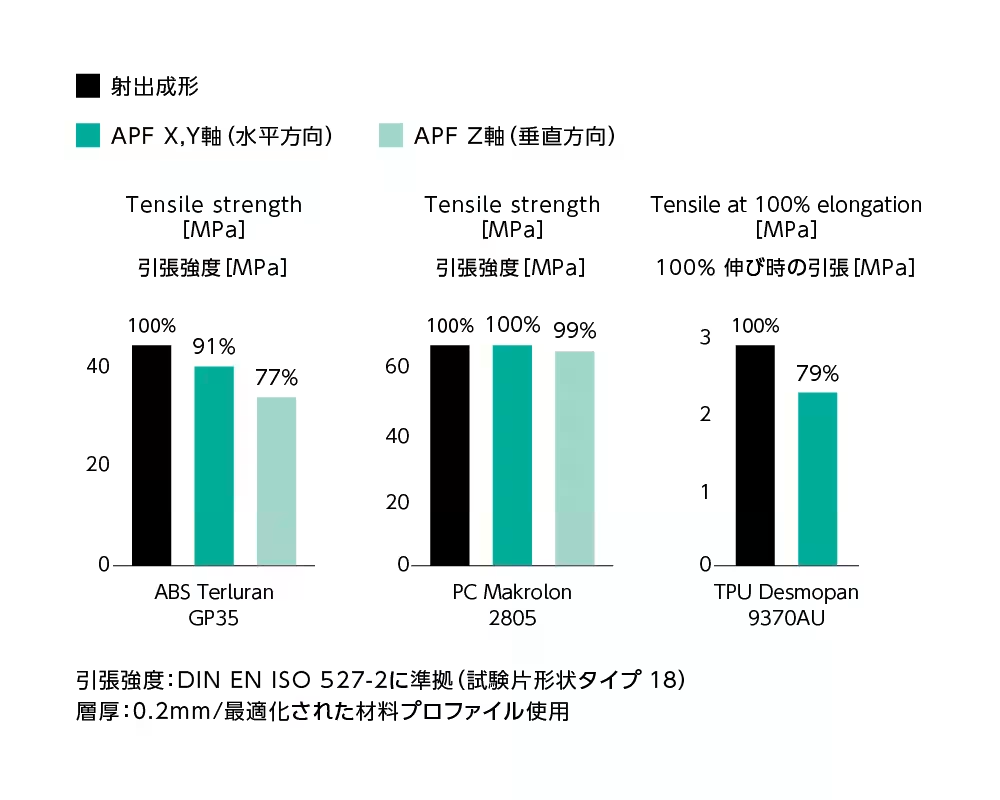

The Freeformer leverages ARBURG’s proprietary Arburg Plastic Freeforming (AFP) process, which uses a screw to plasticize pellets within a cylinder before ejecting them as fine droplets through a nozzle. This highly accurate layering technique achieves complex geometries and exceptional material properties that mirror those of traditional injection molded parts, thereby streamlining the transition from prototyping to mass production.

Optimal Material Versatility

Utilizing the ARBURG Freeformer enables manufacturers to choose from a wide spectrum of materials, from standard plastics like ABS and PA to advanced options such as PEEK and flexible TPU. The printer's capacity to work with FDA-certified and medical-grade materials accelerates the development process, particularly crucial in medical devices and aerospace prototypes where certification can be a bottleneck. Notably, the Freeformer can also produce ultra-soft materials with a Shore A hardness of 10 to 32, making it suitable for a variety of applications across different industries.

Launch Event: A Glimpse at the Future

Japan 3D Printer Co., Ltd. is set to showcase the Freeformer 750-3X at the upcoming Next Generation 3D Printer Exhibition scheduled from July 9 to 11, 2025, at Makuhari Messe. Attendees will witness the Freeformer in action at booth 7 Hall 43-16. Registration is required to attend this significant event.

Specifications of the Freeformer 750-3X

- - Dimensions: 1235 x 1240 x 1913 mm

- - Number of Nozzles: 2-3

- - Build Area: 330 x 230 x 230 mm

- - Positioning Accuracy: +0.022 mm

- - Chamber Temperature: Up to 120°C (200°C with HT option)

- - Material Melting Temperature: Up to 350°C (450°C with HT option)

- - Max Extrusion Pressure: Up to 800 bar

- - Max Material Throughput: 57 cm³/h

- - Nozzle Diameter: 0.2 mm

About Japan 3D Printer Co., Ltd.

Located in Chuo ward, Tokyo, Japan 3D Printer Co., Ltd. is committed to delivering state-of-the-art 3D digital solutions to companies and educational institutions. With a focus on innovation and customer support, the company ensures that clients have access to the latest in 3D technology. To learn more about the new ARBURG Freeformer series and its applications, visit their official website.

For further inquiries:

- - Address: CROSS DOCK HARUMI 1F, 4-7-4 Harumi, Chuo City, Tokyo, 104-0053, Japan

- - Phone: 03-3520-8928

- - Website: 3D Printer Co., Ltd.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.