Innovative Tire Recycling Method Transforms Old Tires into Chemical Resources for a Greener Future

Transforming Waste Tires into Valuable Resources

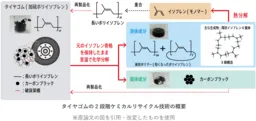

In a significant breakthrough, researchers from the National Institute of Advanced Industrial Science and Technology (AIST) and Bridgestone have developed an innovative technique for recycling used tires. This method leverages the chemical decomposition of rubber at ambient temperatures, enabling the recovery of essential materials such as isoprene and carbon black, both crucial for producing new tires and other products.

The Research Team and Their Findings

Led by Yoshihiro Ueda, Wahyu S. Putro, and Hiroshi Matsumoto among others, the study represents a collaborative effort between AIST's Chemical Process Research Division and Bridgestone. The researchers focused on the chemical breakdown of vulcanized polyisoprene rubber under mild conditions, followed by a thermal decomposition process to retrieve tire raw materials efficiently.

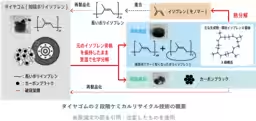

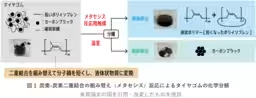

The process begins by introducing a catalyst and solvent into the tire rubber, which is then stirred at room temperature. This initiates the chemical decomposition reaction, breaking the cross-linked polyisoprene rubber into a liquid form that can easily separate the remaining solid carbon black. During this decomposition, the molecular chains shorten while preserving the original isoprene structure, facilitating further thermal breakdown to recover isoprene monomers and other valuable chemicals. The findings from this study lay the groundwork for practical applications of chemical recycling of used tires.

This research was published in the journal "ACS Catalysis" on November 21, 2025, and has major implications for a sustainable future, particularly as the global tire industry, valued at over ¥28 trillion, continues to expand.

The Social Context of Tire Waste Management

As we enter an era where mobility options increase, the demand for tires is expected to continue its upward trajectory. Unfortunately, the majority of used tires are currently processed through thermal recovery, where they are burned for fuel, releasing CO2 in the process. Although retreading offers one form of material recycling, it does not address the larger crises related to resource depletion and climate change. Therefore, innovative chemical recycling methods like this are essential for the sustainable management of tire waste.

Historically, the complexity of tire materials makes chemical recycling a challenging task. Tires are composed of interlinked polymers, carbon black, and other substances like antioxidants, making them difficult to break down into pure reusable materials. Therefore, the successful development of a method that can decompose these complex products chemically is a monumental step towards a more sustainable approach in the tire industry.

The Technical Approach

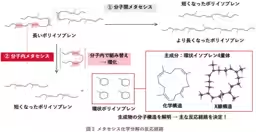

The team’s method harnesses a metathesis reaction to rearrange carbon-carbon double bonds in tire rubber. While previous studies indicated that natural rubber, including polyisoprene, could undergo catalytic metathesis, conventional used tire rubber posed unique challenges due to the inhibitory effects of sulfur compounds, which are prevalent due to the vulcanization process.

To tackle this issue, the researchers focused on identifying catalysts that remain active even in the presence of sulfur. The result was a highly active metathesis catalyst capable of functioning under the unique conditions of vulcanized polyisoprene rubber. They discovered that under their optimized conditions, the short polymer chains produced during decomposition would not simply revert to longer chains, allowing for the efficient formation of liquid polyisoprene that separates easily from carbon black. This study represents the first successful demonstration of the chemical decomposition of vulcanized tire rubber through metathesis under mild conditions without the need for additional reagents.

Potential Future Developments

Building on these findings, researchers plan to expand the method's applicability to other synthetic rubber types, such as butadiene rubber, which may prove chemically amenable to metathesis reactions as well. Moreover, the recently isolated cyclic isoprene tetramer, a novel chemical compound, offers promising opportunities as a new carbon resource.

Collaboratively, AIST and Bridgestone intend to push forward high-efficiency reactions and scalability in anticipation of implementing these chemical recycling technologies in society by the 2030s. This research could transform how we think about waste tires and their potential to become valuable resources instead of environmental burdens, paving the way for a sustainable circular economy in the automotive sector.

Conclusion

With increasing pressures on natural resources and the urgent need to combat climate change, the successful implementation of advanced recycling processes such as this chemical recycling technique could greatly mitigate the environmental impact of waste tires. This pioneering research has the potential not only to revolutionize tire recycling but also to contribute towards a more sustainable future for all.

- ---

Publication Information

- - Journal: ACS Catalysis

- - Title: Two-step chemical recycling of tire rubber to isoprene

- - Authors: Wahyu S. Putro, Yoshihiro Ueda, Hiroshi Yamashita, Naoki Kamei, and others

- - DOI: 10.1021/acscatal.5c05581

For more details, visit AIST Press Release

Topics Energy)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.