Innovative Human Digital Twin System Enhances Construction Machinery Usability

Enhancing Construction Machinery Usability with Human Digital Twin System

In a remarkable development, the National Institute of Advanced Industrial Science and Technology (AIST) has unveiled a novel Human Digital Twin system aimed at improving construction machinery usability through a human-centered design approach. Collaborating with Komatsu, the initiative focuses on enabling product developers to objectively assess and refine prototypes by experiencing their use in real-time.

The Importance of Human-Centered Design

In recent years, human-centered design (HCD) has become a cornerstone of product development across industries, particularly in sectors like automotive, medical devices, and software applications. The core principle of HCD is to ensure that products are designed for optimal human usability, safety, and comfort. This methodology not only reduces operator stress but also enhances productivity at construction sites. However, achieving high quality typically requires iterative cycles of testing, evaluation, and redesign, which can lead to significant labor and costs.

To address these challenges, AIST and Komatsu designed a system that utilizes human digital twins, allowing real-time monitoring of human activities in a digital environment. This setup ensures that developers can not only experience the functional aspects of machinery but also receive immediate feedback on performance through simulations and analysis.

Integration and Validation

The system was validated by applying its capabilities to an ergonomic redesign of armrests installed in construction machinery cabs. By allowing developers to operate prototypes while tracking their physical movements, discussions centered around enhancing user experiences were significantly enhanced. Through detailed analysis of operators' movements, developers engaged in discussions that led to the hypothesis that existing armrests hindered elbow movement during lever operations.

By incorporating this movement data into CAD software, a new armrest design that promotes better motion was conceptualized. Subsequent evaluations demonstrated that the improved design allowed more natural movement without obstruction. Observers noted that real-time digitalization provided insights that could not be easily captured through traditional methods, enhancing communication and understanding among participants.

Advancements Beyond Design

The implementation of this system employs advanced technologies such as OptiTrack's motion capture and AIST’s proprietary digital human software, DhaibaWorks. This amalgamation enables quantitative assessments of operator movements from kinematic and dynamic perspectives, while also providing high-quality rendering and integration with CAD for enhanced visualization.

The beneficial outcomes of the proposed system signal a transformative approach to human-centric design in machinery development, potentially leading to faster design cycles and more user-friendly products. As the AIST presentation on this research approaches during the SI2025 event in December, anticipation builds around these advancements in construction technology.

Looking Ahead

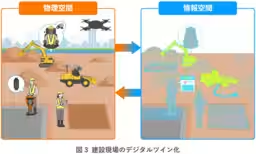

Looking to the future, AIST and Komatsu aim to expand the application of digital twin technology from mere design environments to whole construction sites. By establishing digital twins encompassing machinery, operators, and the surrounding fields, the vision is to develop a metaverse space that supports project managers and remote operators effectively. This ambitious goal holds the promise of revolutionizing the construction industry, enhancing both safety and productivity.

In conclusion, the Human Digital Twin system developed through this collaboration represents a significant leap forward in improving machinery usability, showcasing the fusion of digital innovation with practical applications in construction. This bold step towards integrating human experiences into the design and functionality of construction equipment has the potential to redefine operational standards.

For more information on this groundbreaking research, visit the AIST press release.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.