Nippon Kinzoku Launches Eco-Friendly Products with Fine Profile® Technology

Nippon Kinzoku's Innovative Eco-Product Initiative

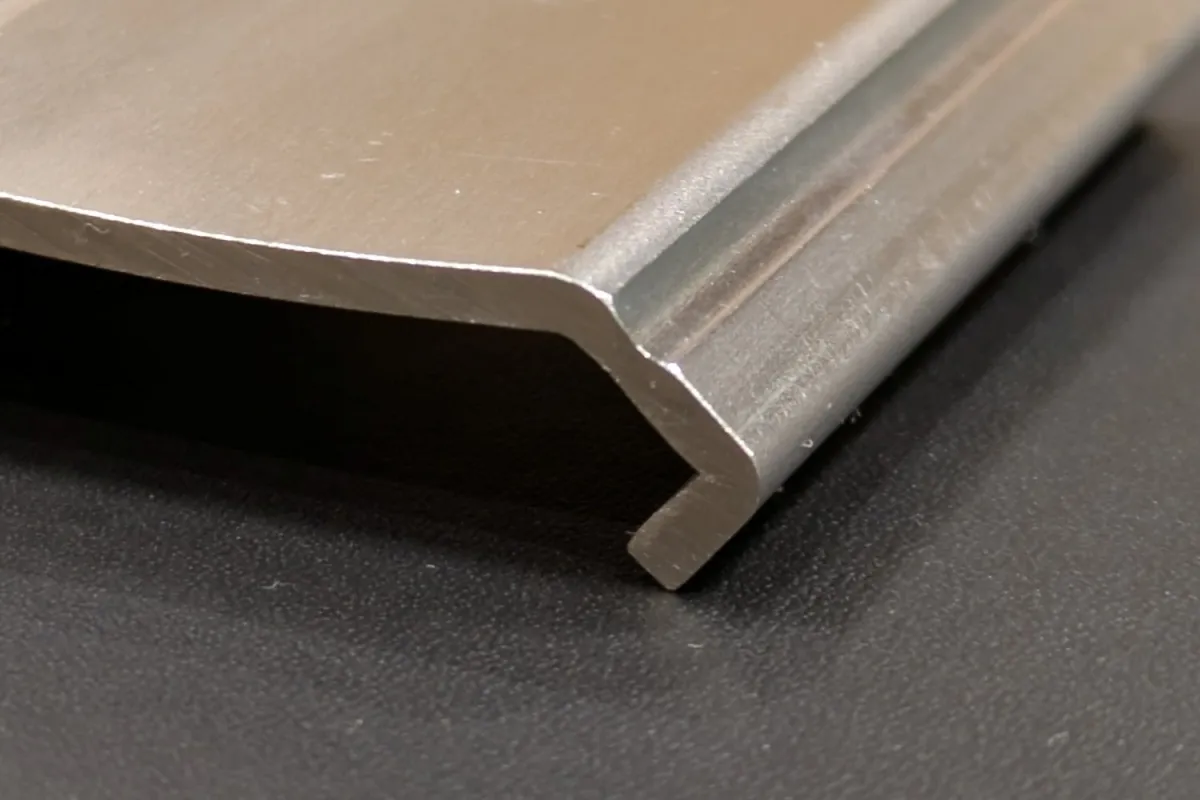

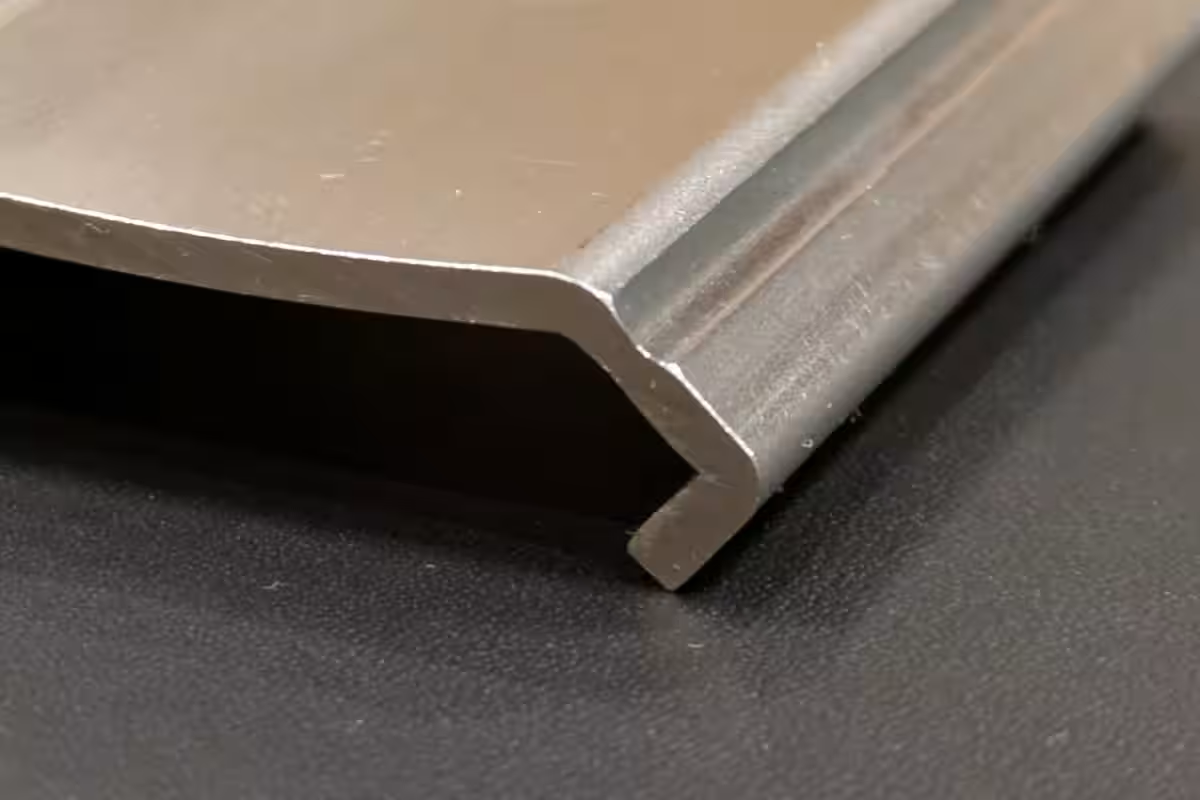

Nippon Kinzoku Co., Ltd., based in Minato, Tokyo, has officially begun expanding its innovative range of eco-friendly products, branded as "Eco Products". This initiative is underpinned by the company's proprietary Fine Profile® technology. The company's announcement heralds an exciting phase where they leverage advanced manufacturing processes developed at their Fukushima factory. This technology enables the production of precision irregularly shaped rolled products, significantly aiding efforts toward environmental sustainability.

Background and Objectives of Development

In recent years, the manufacturing sector has faced pressing challenges to reduce costs alongside minimizing environmental impact. The processing of metal components often results in substantial material waste and high energy consumption during manufacturing processes. In response, Nippon Kinzoku has focused on solving these manufacturing challenges while promoting environmental conservation.

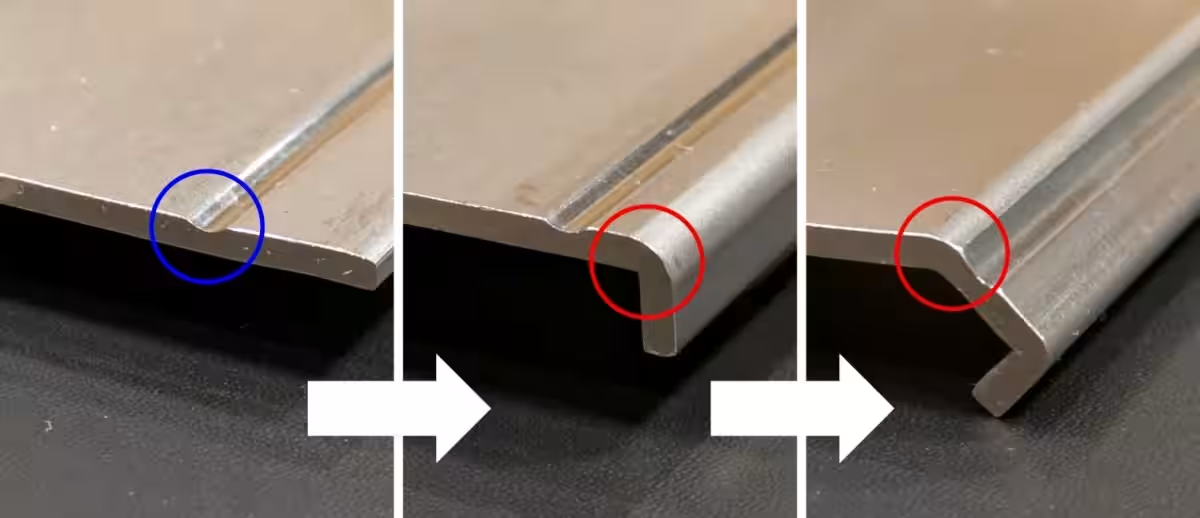

With the comprehensive combination of various metal processing technologies honed at their Fukushima factory, Nippon Kinzoku has developed a unique composite plastic processing technology. This approach allows for near net shape manufacturing, which minimizes secondary processing needs, thereby reducing material loss and shortening production processes.

Features of the Composite Plastic Processing Technology and Value Proposition as Eco Products

Nippon Kinzoku's innovative composite plastic processing technology is characterized by several unique features that significantly contribute to lower environmental burdens and enhanced value for customers:

- - Realization of Complex Cross-Sections and Major Material Waste Reduction

- - Streamlining Customer Manufacturing Processes and Enhancing Productivity

- - Stable, High-Quality Production Through Continuous Coil Material Forming

Due to these features, products developed using this technology meet the company's eco-product accreditation standards, thereby reinforcing their commitment to sustainability.

Future Outlook

Nippon Kinzoku is committed to actively promoting this composite plastic processing technology as eco-friendly products, aiming to meet diverse customer needs. Guided by the 11th Management Plan, "NIPPON KINZOKU 2030," the company emphasizes the concept of Near Net Shape processing to foster the creation of new value that is both beneficial for humanity and the planet.

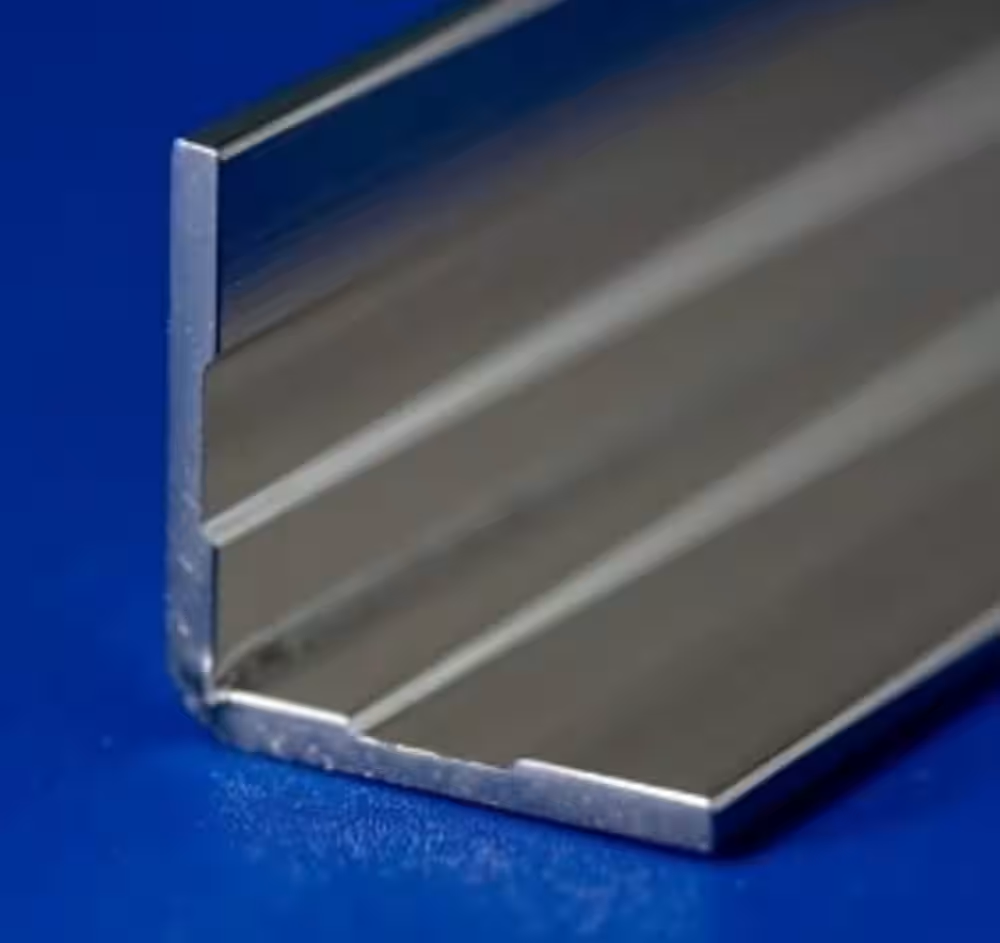

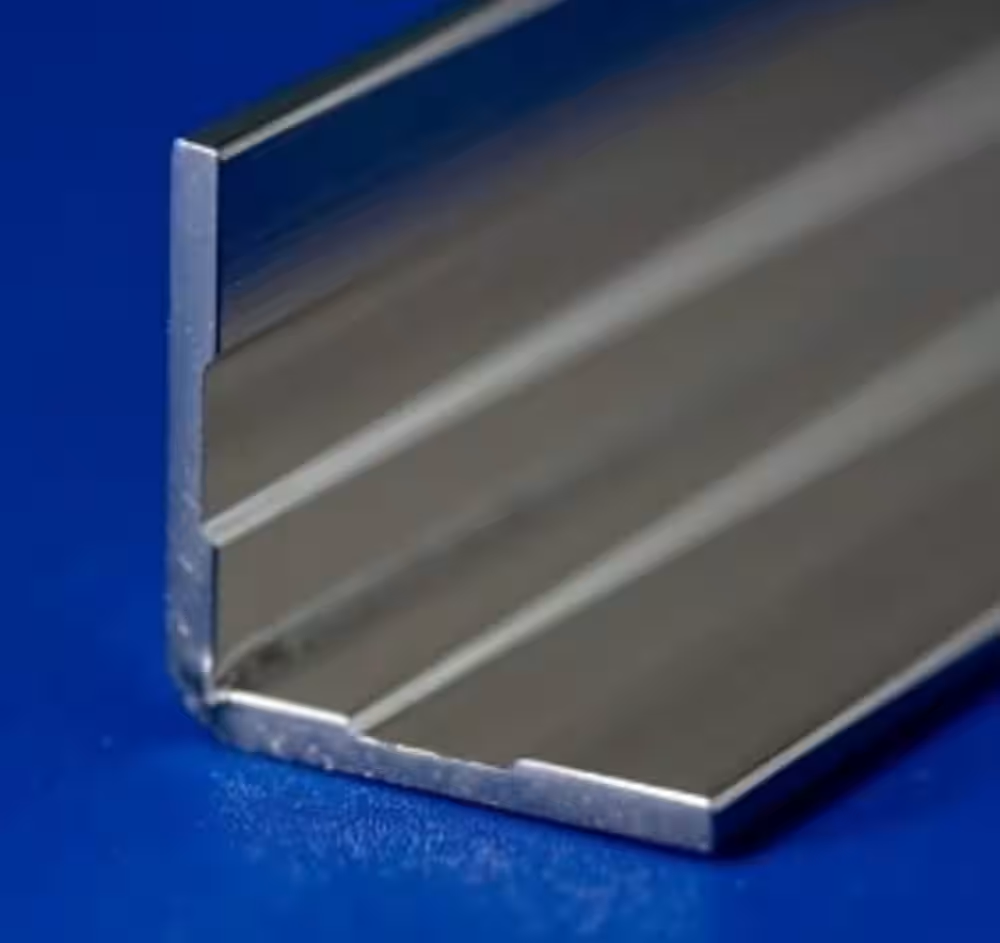

Overview of Fine Profile®

Fine Profile® refers to a range of products processed from non-ferrous and iron-based metals using unique rolling techniques to achieve varying thicknesses across widths, serving as an effective alternative to cutting and grinding processes while supporting the reduction of manufacturing costs and improvement in material yield.

More information can be found on the Nippon Kinzoku official website.

Fine Profile is a registered trademark of Nippon Kinzoku.

Fukushima Factory Overview

The Fukushima factory specializes in precision irregular rolling, roll forming, and pressing processes. It is a technical hub for producing Fine Profile® and other standard shapes, with skilled craftsmen capable of flexibly addressing diverse customer needs cultivated over years of experience.

Learn more about the Fukushima facility on the Nippon Kinzoku website.

About the 11th Management Plan "NIPPON KINZOKU 2030"

The vision of Nippon Kinzoku is to collaboratively create new value that is gentle to people and the planet. By utilizing unique rolling and composite forming technologies, the company aims to contribute broadly to society while realizing product performance at the material level. Their strategic focus revolves around three key terms: Multi & Hybrid Material, Near Net Shape, and Near Net Performance, pushing forward with innovative technology and products to meet emerging market demands.

For more information, visit Nippon Kinzoku Investor Relations.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.