SEFAR GMP BAG Achieves Positive List Compliance for Food Safety Standards

SEFAR GMP BAG Achieves Positive List Compliance

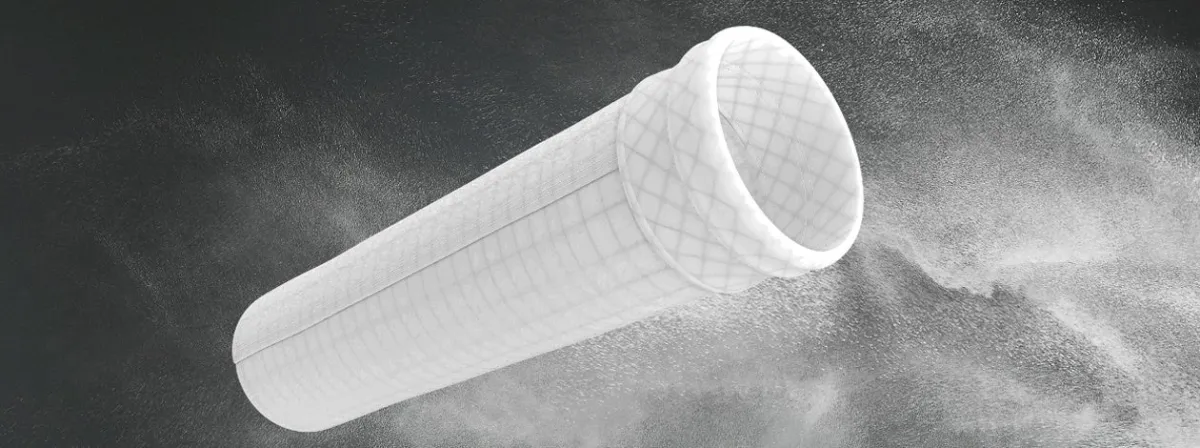

SEFAR, a global leader in precision mesh products, has announced that its SEFAR GMP BAG — designed for powder filtration in the pharmaceutical and food production industries — has recently been recognized as compliant with Japan's Positive List food safety regulations. This significant achievement highlights SEFAR's dedication to providing a safe and secure manufacturing environment in the production of various powder substances.

Key Features of the SEFAR GMP BAG:

The SEFAR GMP BAG offers several distinct advantages that fundamentally enhance manufacturing processes in food and pharmaceutical sectors:

Positive List Compliance

The SEFAR GMP BAG ensures user confidence through its adherence to the Positive List standards, complying with both domestic and international regulatory requirements, which is essential for food and drug safety.

High-Quality Materials

Manufactured from raw materials that meet FDA and EU standards, the SEFAR GMP BAG is designed with safety at the forefront, making it suitable for use in both food and pharmaceutical applications.

Production in Clean Environments

The bags are produced in a strictly controlled white room setting, significantly reducing the risk of foreign material contamination during manufacturing. This attention to detail is crucial for maintaining product integrity and safety.

Optimal Design for Powder Filtration

Specifically engineered for powder filtration, the SEFAR GMP BAG meets the needs of both the pharmaceutical and food industries, including confectionery production. Its design maximizes filtration performance while minimizing handling-related risks.

Superior Airflow Performance

The SEFAR GMP BAG is engineered to facilitate efficient powder transport and filtration, significantly decreasing the likelihood of process blockages and pressure spikes. This adaptability can enhance the overall productivity of powder manufacturing processes.

Customized Manufacturing

SEFAR offers tailor-made solutions that fit seamlessly into any machinery configuration. This adaptability enables easy replacement of existing equipment or incorporation into new installations, enhancing operational flexibility.

Extensive Applications

The SEFAR GMP BAG is useful across a range of applications, particularly within the pharmaceutical industry (such as in fluid bed granulators and drying/transport stages) and food sectors (including broad powder filtration processes).

SEFAR remains committed to continuous improvement in providing advanced powder filtration solutions, ensuring our clients can enhance the efficiency and quality of their manufacturing processes.

For further inquiries regarding SEFAR GMP BAG, please contact:

Company: SEFAR

Contact Person: Fujimoto

Phone: 052-569-4868

E-Mail: [email protected]

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.