Innovative IoT Solution Aims to Cut Waste Loss in Biopharma Industry

Introduction

In a groundbreaking initiative, Esmat Co., Ltd. has publicly shared a case study highlighting its collaboration with Kyowa Kirin's Takasaki plant. The aim of this partnership is to tackle waste loss in the biopharmaceutical industry, potentially saving approximately 20 million yen in wasted materials. Utilizing their state-of-the-art IoT-based inventory management service, SmartMat Cloud, they are poised to enhance efficiency and mitigate stockout risks associated with culture media, a key element in bio-pharmaceutical production.

Background

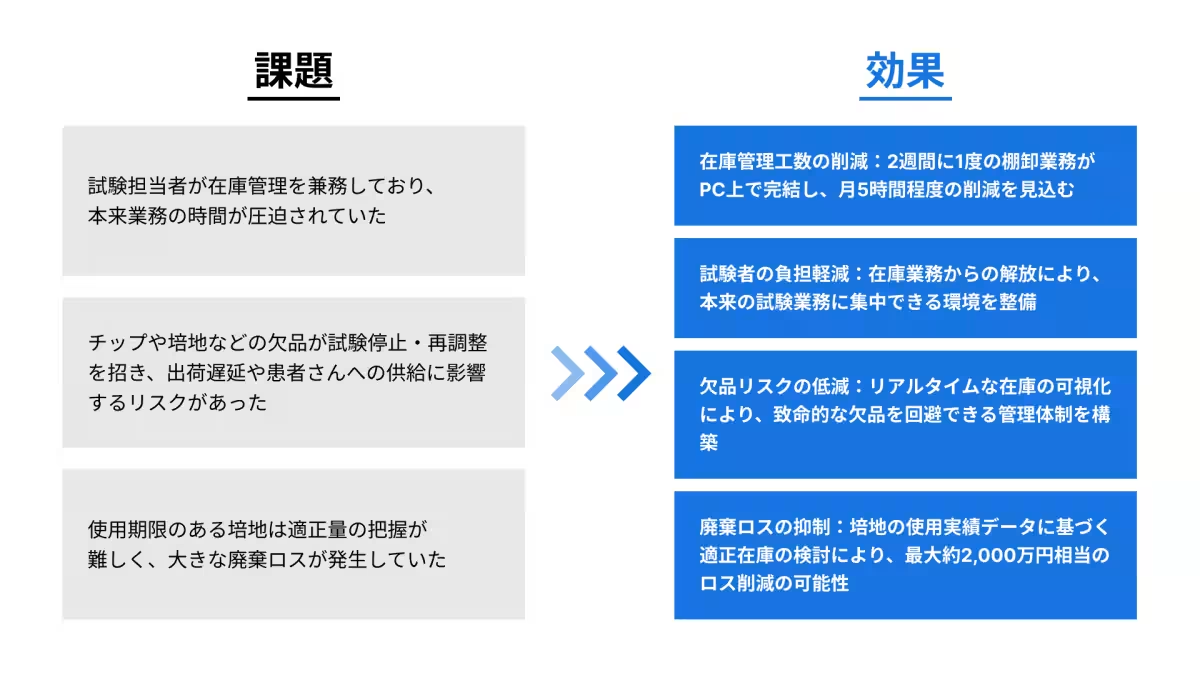

At the Takasaki facility of Kyowa Kirin, quality control personnel responsible for managing bio-pharmaceutical materials like culture media and reagents struggled to focus on their core tasks. Concurrently handling inventory management led to distractions and inefficiencies. As a result, a tendency to maintain excessive stocks of culture media arose, driven by concerns that any stockout could halt critical testing processes. Unfortunately, this resulted in substantial waste, with unused culture media often exceeding its expiration date, potentially costing the company about 20 million yen annually.

Faced with this pressing issue, the necessity for a reliable inventory management solution that addresses the vague anxieties related to stock levels and stockout predictions became increasingly apparent. Thus, the introduction of SmartMat Cloud was deemed essential.

Challenges and Solutions

SmartMat Cloud Overview

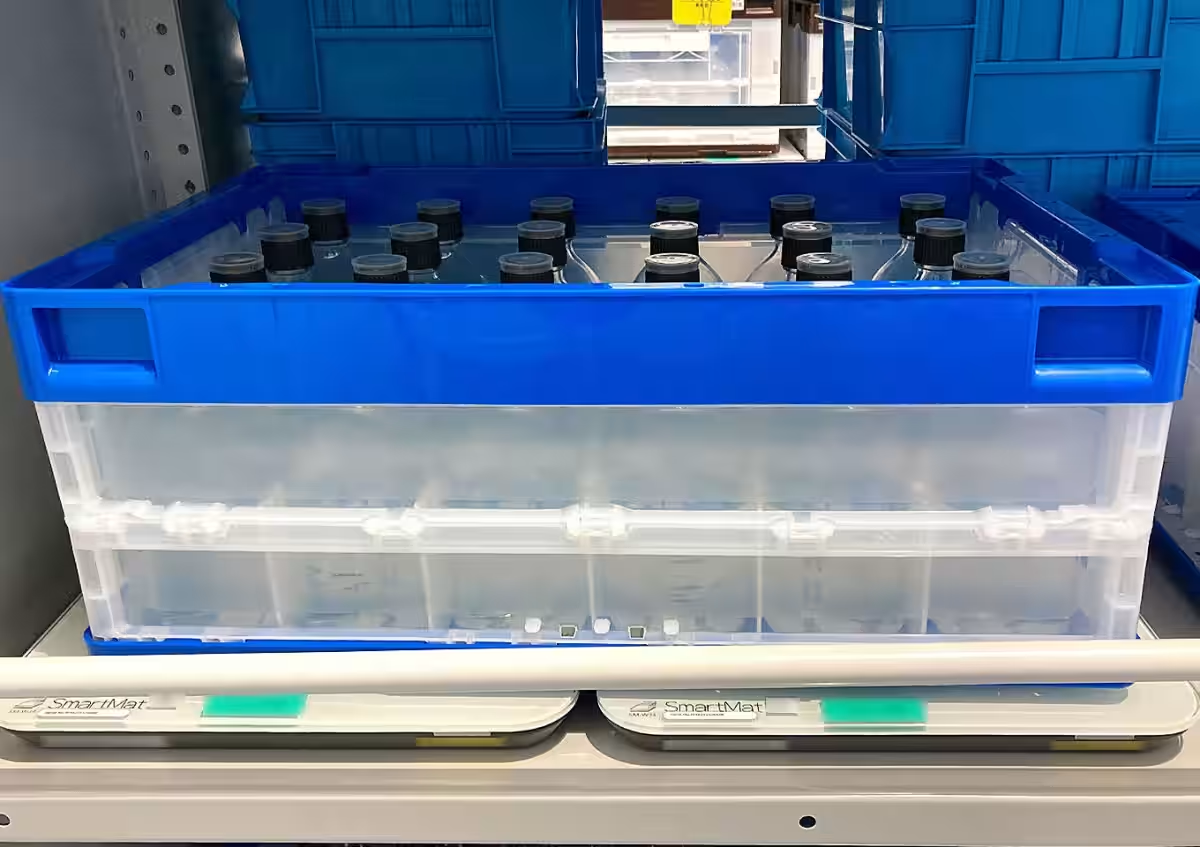

SmartMat Cloud simplifies and automates inventory management by visualizing real-time stock levels of a range of products using IoT technology. This SaaS solution streamlines countless manual inventory tasks that routinely demanded high labor input, achieving efficiency and accuracy that manual methods simply cannot provide, particularly for real-time stock counts.

By automating the inventory tallying process and managing orders seamlessly, SmartMat Cloud not only reduces labor costs but also increases precision in inventory management. This innovative platform has gained traction since its launch in winter 2018, being adopted by over 1,200 clients across diverse sectors, including manufacturing, service industries, and healthcare institutions.

Impact in the Biopharma Sector

The introduction of SmartMat Cloud at Kyowa Kirin's Takasaki plant represents a significant technological advancement in biotech inventory management. By addressing the specific challenges faced in quality control and stock management, SmartMat not only reduces costs tied to waste but enhances operational efficiency, allowing quality control professionals to focus on their primary roles without the hassle of manual stock tracking.

The positive outcomes are not limited to waste reduction; the implementation of SmartMat Cloud also fosters a culture of innovation and change within the biomedical sector. As companies confront the increasing demands of a competitive market and a need for sustainability, solutions like SmartMat Cloud are paving the way for a more efficient future in inventory management.

Company Background

Esmat Co., Ltd., previously known as Smart Shopping, aims to make daily material flow more efficient through its IoT-based automated inventory solutions. Their flagship product, SmartMat Cloud, is specifically developed to automate inventory management, stocktaking, and ordering processes for B2B clients, including those in manufacturing and healthcare sectors.

- - Company Name: Esmat Co., Ltd. (formerly Smart Shopping)

- - Location: 2-9-5 Higashi Gotanda, Shinagawa-ku, Tokyo, Japan

- - Representatives: Takayuki Shiga, Hidetoshi Hayashi

- - Founded: November 2014

- - Website: Esmat

Through innovative solutions like SmartMat Cloud, Esmat is transforming inventory management, offering substantial savings and efficiencies to industries grappling with the challenges of waste and operational risks.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.