Nexa Warehouse-Smart Pack: Revolutionizing Logistics with Data Analysis Capabilities

Nexa Warehouse-Smart Pack: A Game Changer for Logistics Warehousing

In the evolving landscape of logistics, efficiency and data-driven decision-making are paramount. Nexa Ware, a joint venture between Tsubakimoto Chain and KDDI Corporation, has taken a significant step towards optimizing warehousing operations with the introduction of its latest package: the Nexa Warehouse-Smart Pack. Officially launching on February 28, 2026, this innovative solution comes equipped with the Nexa Warehouse-Optimizer, a data analysis service designed to establish seamless visibility and analysis of warehousing operations.

Understanding Nexa Warehouse-Smart Pack

The Nexa Warehouse-Smart Pack is specifically tailored for logistics warehouses, facilitating automation and operational efficiency by integrating multiple material handling equipment, robotics, and systems. This comprehensive package aims to alleviate the time and cost burdens associated with equipment implementation, ensuring a smoother transition for facility setup.

By incorporating the Optimizer as a standard feature—free of charge—customers will benefit from sophisticated reporting capabilities that enhance operational improvements without incurring additional costs. The Smart Pack empowers customers by providing real-time insights into equipment performance and operational dynamics, paving the way for refined efficiency in logistics management.

Benefits of the Optimizer Implementation

The Optimizer brings several key advantages to operations using the Smart Pack:

1. Enhanced Visualization and Analysis: It enables customers to analyze and visualize the performance of the Smart Pack, yielding optimal improvements based on specific operational conditions. It even outperforms traditional single-unit operations.

2. Support for Visualizing Results: The Optimizer helps visualize the results of implementing the Smart Pack, allowing for automated reporting and a reduction in management workload through quantitative reports.

3. Advanced Proposals for Automation: Leveraging operational data, the Optimizer proposes further automation and enhancements—contributing to the customer's business growth (available as a paid service).

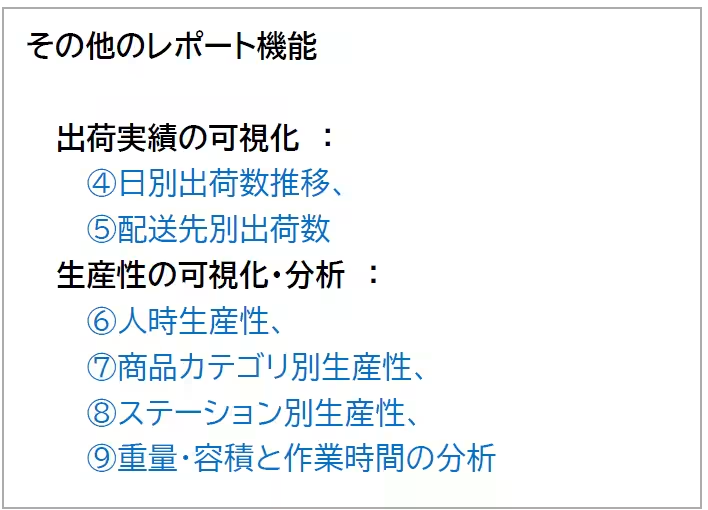

Reporting Capabilities of the Optimizer

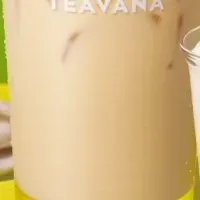

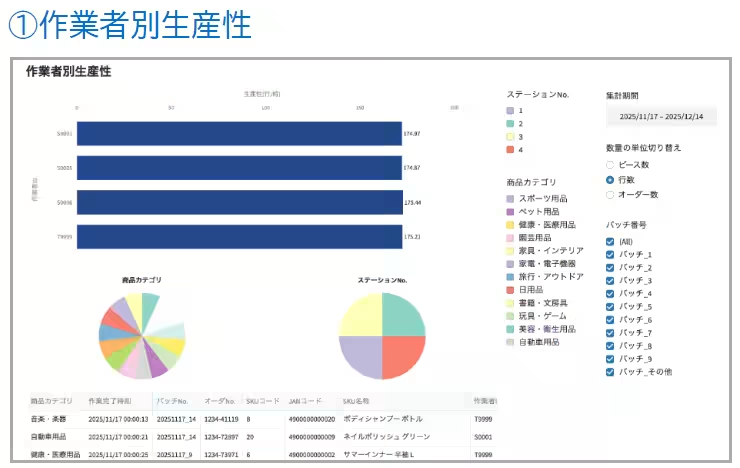

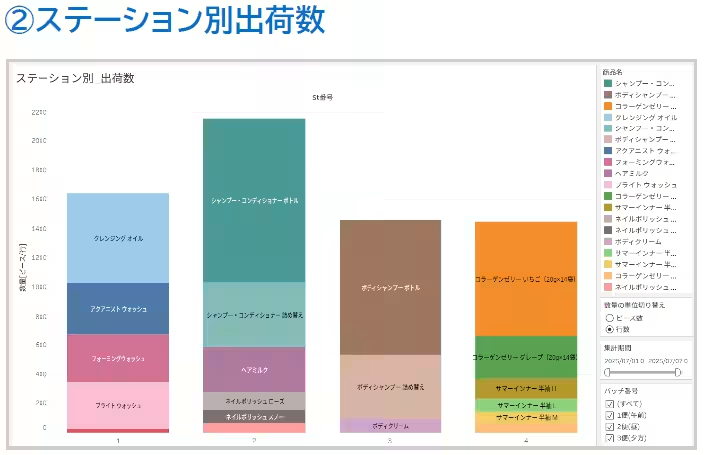

The reporting functions of the Optimizer are robust. Customers can utilize nine different reporting types to visualize and analyze equipment and task performance, which supports daily operational improvements and productivity enhancements. Some highlights include:

- - Comparative Productivity Analysis: Assess the productivity of individual workers based on work volume per hour, aiding in skill evaluation and shift management.

- - Shipment Volume Visualization: Identify fluctuations in shipping numbers over specified periods, providing insights for balanced adjustments.

- - Order Combination Analysis: Gather data on combinations of products shipped in single orders, displaying the most common combinations to inform location adjustments.

Future of Smart Pack with Optimizer

Nexa Ware remains committed to expanding the lineup of the Smart Pack, ensuring that new packages will also come standard with the Optimizer service. By reducing the temporal and financial burdens associated with automation equipment implementation, the company aims to foster efficient utilization of automated systems through effective data utilization. This initiative represents Nexa Ware's dedication to driving digital transformation in logistics (DX), ultimately contributing to solutions for various societal challenges.

For further inquiries regarding the products, please reach out to Nexa Ware's Sales Engineering Department at:

- - Phone: 03-6841-3867

- - Contact Form: Nexa Ware Contact

Company Websites:

This innovative approach by Nexa Ware marks a transformative milestone in logistics warehousing, emphasizing the crucial role of data analysis in enhancing operational efficiencies and adapting to market demands.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.