Introducing Innovative Ceramic Powder for Metal 3D Printing by Canon Marketing Japan

Canon Marketing Japan Innovates with AY-01F Ceramic Powder

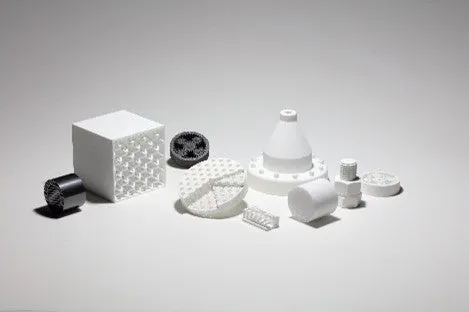

In a significant move for the 3D printing industry, Canon Marketing Japan Inc. announced the upcoming launch of its AY-01F ceramic powder on February 13, 2026. This new material, developed by Canon Chemicals Co., enables the use of metal 3D printers to produce high-quality ceramic components while eliminating the need for resin binders and debinding processes, leading to enhanced precision and reduced production time.

The Growing Demand for Ceramic Components

In recent years, there has been a surge in the demand for ceramic parts within cutting-edge industries such as aerospace, semiconductor manufacturing, and energy sectors. Ceramics are valued for their heat resistance, chemical stability, and electrical insulation properties. However, the conventional methods of machining and casting ceramics often pose limitations in achieving high-precision parts. Traditional 3D printing techniques using ceramic materials typically involve resin binders, resulting in shape changes during firing and increased manufacturing lead times due to the required debinding steps.

The Advantage of AY-01F

The AY-01F ceramic powder is derived from alumina-based materials designed for intricate shaping without the complications of resin binders. It can be utilized directly in existing metal 3D printers following the Laser Powder Bed Fusion (LPBF) method. The absence of resin binders allows for consistent shape retention during the sintering process and reduces shrinkage to less than 2% during firing. This capability is particularly advantageous for the manufacturing of thick and complex internal structures, which previously required more intricate handling in traditional ceramic practices.

Key Features of AY-01F:

1. Direct Use with Metal 3D Printers: The unique formulation of AY-01F incorporates various oxides to control laser absorption and melting behavior, making it compatible with high-power fiber laser-equipped LPBF printers for effective melting and layering of ceramics.

2. High Precision and Shorter Lead Times: Without the need for a debinding step, the AY-01F starts with significant time reductions in production, slashing lead times by nearly 75%. The regulation of shrinkage guarantees high dimensional stability even for complicated designs.

3. Flexibility in Design: AY-01F enhances design freedom typical of 3D printing, allowing for the creation of complex lattice structures, ceramic cores for casting, and hybrid structures with different pore patterns; geometries that were challenging or impossible to achieve with conventional manufacturing techniques.

Future Prospects

To address a broader range of manufacturing needs, Canon Marketing Japan, alongside Canon Chemicals, aims to expand the diversity of ceramic materials, including silica and silicon carbide variants, as it continues to push the boundaries of next-gen manufacturing innovations. By enhancing design flexibility and shortening development cycles, AY-01F aims to contribute significantly to advancing manufacturing technologies and boosting industrial competitiveness.

Product Availability

The AY-01F ceramic powder will be available in different forms tailored to customer needs:

- - Sale of Ceramic Powder: For customers who already utilize LPBF metal 3D printers, only the AY-01F ceramic powder will be sold.

- - Contract Manufacturing Services: For those without metal 3D printers, Canon can facilitate access to contracted manufacturing services through its partners.

For inquiries, the general public can reach out to Canon Marketing Japan’s Industrial Equipment Division at 03-3740-3356. More information is available on their website: Canon Ceramic Powder 3D Print.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.