CEC Launches Power Consumption Simulation to Support Decarbonization in Manufacturing

CEC Introduces Power Consumption Simulation for Carbon Neutrality

On December 19, 2025, CEC (Creative Engineering Corporation) will launch its innovative power consumption simulation tool designed to support energy efficiency and decarbonization in production facilities. This new feature, part of the existing 'RaAP' (Rapid Analysis and Planning) optimization tool, will enable manufacturing plants to visualize and analyze their energy consumption patterns.

With the power consumption simulation tool, manufacturers can assess their electrical usage to see "when" and "how much" energy is being consumed by each piece of equipment in their production line. This data will help companies obtain a clear picture of their CO2 emissions, allowing them to objectively evaluate their potential for achieving carbon neutrality.

CEC aims to implement this feature within 30 manufacturing companies by 2030, reinforcing its commitment to finding clean and efficient production methods. This initiative not only aligns with corporate sustainability goals but also contributes to the overarching aim of creating a sustainable society.

Background

In 2023, the Japanese government passed the GX Promotion Law, aimed at achieving carbon neutrality by 2050. This legislation mandates a broader scope for energy management, obliges a shift to non-fossil energy sources, and sets new optimization targets for electricity demand. Consequently, energy-intensive industries like manufacturing are under increasing pressure to enhance their energy saving and decarbonization efforts.

To address these mounting demands, CEC began developing new frameworks for utilizing energy generated within production facilities. They recognized the necessity of integrating power consumption considerations into the design of production processes, thus starting their journey to tackle social and environmental challenges.

As part of this effort, CEC has enhanced its own product, RaAP, by incorporating a power consumption forecasting feature that helps simulate and analyze energy usage effectively.

Features of the Power Consumption Simulation

By adding the GX power consumption simulation feature to RaAP, manufacturers can utilize it for several key applications: pre-verifying new production lines, understanding existing line performance, making improvements, and preparing for fluctuations in production. Specifically, users can set power consumption parameters for production equipment and link the generated CO2 emissions to specific products produced.

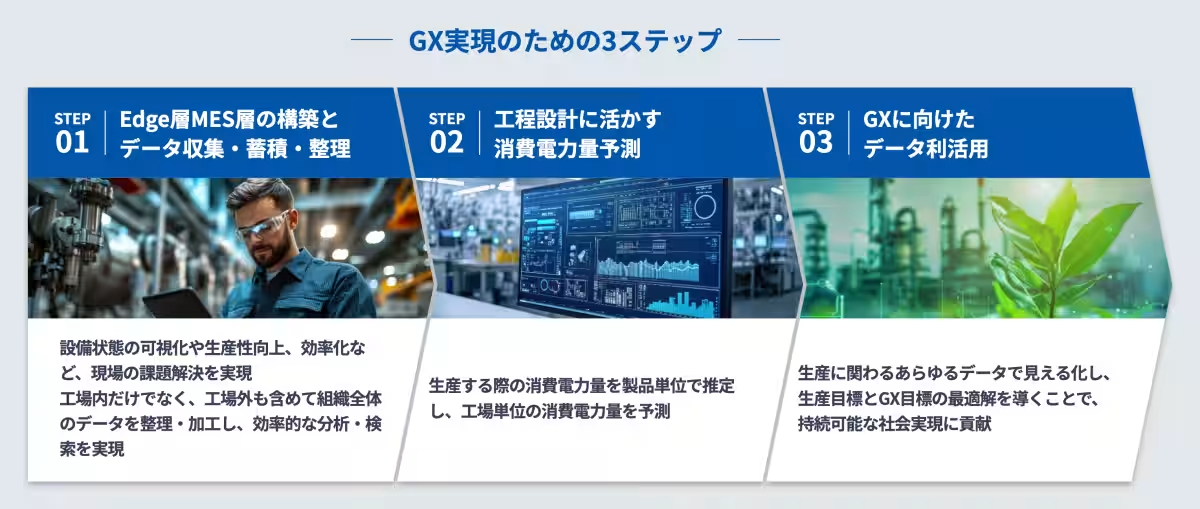

Steps Towards GX Implementation

CEC’s goal for facilitating GX in production facilities involves a three-step approach:

1. Organizing and processing relevant manufacturing data to enable efficient analysis and search capabilities.

2. Predicting power consumption using simulation techniques.

3. Utilizing the gathered data to provide continuous support in discovering optimal solutions for GX goals.

Pricing

The monthly usage fee for RaAP starts at 200,000 yen (excluding tax) for the minimum configuration. Either annual or monthly contracts are available. Existing RaAP users can add this feature at a separate, quoted cost.

About RaAP

RaAP is a simulation software that allows for a swift and straightforward comparison of factory layout designs and internal logistics against actual production capabilities. For more information, visit the RaAP product site.

It is important to note that CEC and RaAP are trademarks or registered trademarks of their respective companies.

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.