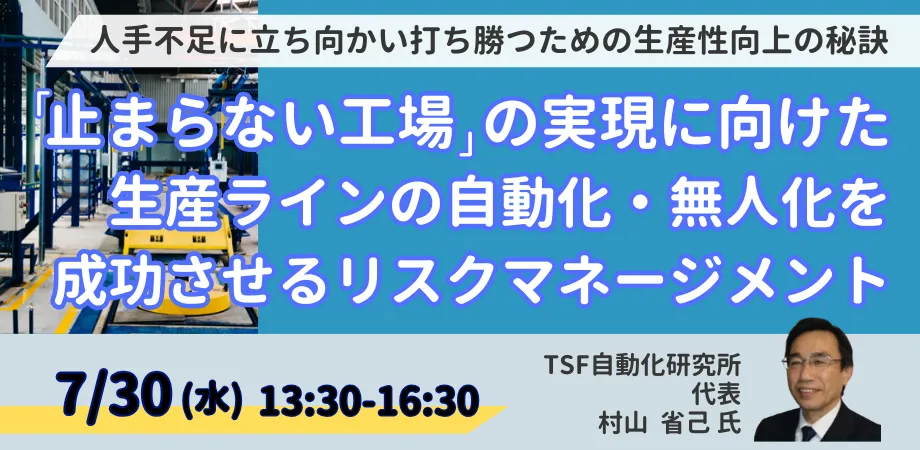

Mastering Automation in Manufacturing: Achieving the 'Unstoppable Factory' Through Effective Risk Management

Seminar on Automation and Risk Management in Manufacturing

On July 30, 2025, Japan Planning Institute (JPI) is hosting an exclusive online seminar featuring expert Shoki Murayama from TSF Automation Institute. The seminar will delve into the critical subject of risk management essential for successfully implementing automation and unmanned operations in manufacturing facilities, aiming to realize the vision of the 'unstoppable factory.'

Manufacturing in Japan is currently facing significant challenges, including rising raw material and energy costs, leading to a decline in economic sentiment. Additionally, the ongoing reduction in the workforce within the manufacturing sector, driven by both the reevaluation of supply chains and a decreasing number of employees, has made shortages in manpower especially noticeable. Industries are increasingly struggling to secure personnel for maintaining production, particularly during night shifts. Consequently, there is a rapidly rising demand for automation and unmanned operations to alleviate reliance on human labor.

However, the solution is not simply to replace workers with robots; it requires a thorough understanding of various risks associated with automation. The key to effectively utilizing robots involves exploring potential risks ahead of implementation and formulating preemptive strategies. This seminar will outline essential ideas and approaches for advancing automation and unmanned solutions to address labor shortages, ultimately enhancing productivity.

Seminar Outline

1. Increasing 'Automation Levels' to Achieve Labor Reduction

(1) What should be done to address the labor shortage?

(2) Defining 'Automation Levels': What does it mean for production lines?

(3) Methods for reducing labor in machining and automating operations, including night-time automated processes without setup.

(4) Ensuring unmanned assembly processing: What are the necessary steps?

2. Identifying and Mitigating 'Automation Risks'

(1) Key points for selecting robots: Can robots truly replace manual labor?

(2) Risks associated with automation layout: Is it necessary to have three robots for automation?

(3) Designing countermeasures for automated layouts: How should these be structured?

3. Avoiding Unnecessary Automation

(1) Essential preparations before automating: Steps for improving the facility in advance.

(2) Assessing feasibility: How to determine what can be automated and what cannot?

(3) The integral role of IoT in automation: How to leverage data collected from equipment.

4. Who is Responsible for Implementation? From Planning to Payback!

(1) Capital investment planning: Development of plans by production technology, with approval by managers and executives.

(2) Designing and creating automation equipment: The quality of design dictates the success of automation.

(3) Implementation and return on investment: Quality is assessed based on process capability, and unrecouped investments are the responsibility of the entire company.

5. Q&A Session

Following the Q&A, participants will have an opportunity for individual online discussions with the instructor.

Participation Options

Participants can choose between live streaming or accessing an on-demand archive (available for two weeks, allowing viewers to watch at their convenience). Please note: In-person attendance is not available.

Seminar Fee

- - Individual: ¥37,250 (tax included)

- - Discounts for two or more participants: ¥32,250 (if registered simultaneously from the same company or related companies).

For further details and registration, please visit: JPI Seminar Registration

Post-Seminar Opportunities

After the seminar, there will be a chance for participants to ask questions to the instructor and connect with other attendees, facilitating networking and possibly the emergence of new business opportunities.

Contact Information

Japan Planning Institute

5-2-32 Minami Azabu, Minato-ku, Tokyo 106-0047

TEL: 03-5793-9761

FAX: 03-5793-9767

URL: https://www.jpi.co.jp

About JPI

The Japan Planning Institute has been providing valuable information through exclusive seminars for nearly 50 years, aiming to support executive and senior management in executing national policies and projects, acting as a bridge between governance, public administration, and the private sector.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.