Fumakilla Streamlines Logistics by Adopting DD Plus for Electronic Delivery Slip System

Fumakilla Implements DD Plus for Enhanced Logistics Efficiency

Fumakilla Co., Ltd., headquartered in Chiyoda, Tokyo, has taken a significant step towards streamlining logistics operations by implementing the electronic delivery slip system named DD Plus. This initiative, made possible through collaboration with Atago Warehouse Co., Ltd., Japan Pallet Rental Co., Ltd. (JPR), and TSUNAGUTE, aims to tackle challenges in the logistics industry and enhance efficiency in delivery processes.

Background and Purpose

The logistics sector is currently grappling with pressing issues, particularly the severe shortage of truck drivers, often referred to as the “Logistics 2024 Problem.” The burden of managing paper-based delivery slips, which vary in specifications from one company to another, has become a significant challenge affecting the workload of truck drivers and logistics locations. To address this issue, the Japanese government has been advocating for the standardization and electronicization of delivery slips, aiming to improve operational efficiency.

In light of these challenges, Fumakilla set out to alleviate the burdens associated with traditional delivery slip processing. With the support of TSUNAGUTE, a company renowned for its extensive knowledge and experience in logistics digital transformation (DX), Fumakilla decided to adopt the DD Plus system offered by JPR.

Overview of the Initiative: Automation and Labor Saving through System Integration

The integration of Atago Warehouse’s Warehouse Management System (WMS) with DD Plus has successfully automated what was once a manual process of generating delivery slips. This transition has significantly reduced the labor required for slip issuance, contributing not only to labor-saving but also minimizing the risk of human error. The expectation is that this new system will also help reduce wait times for truck drivers, further optimizing logistics operations.

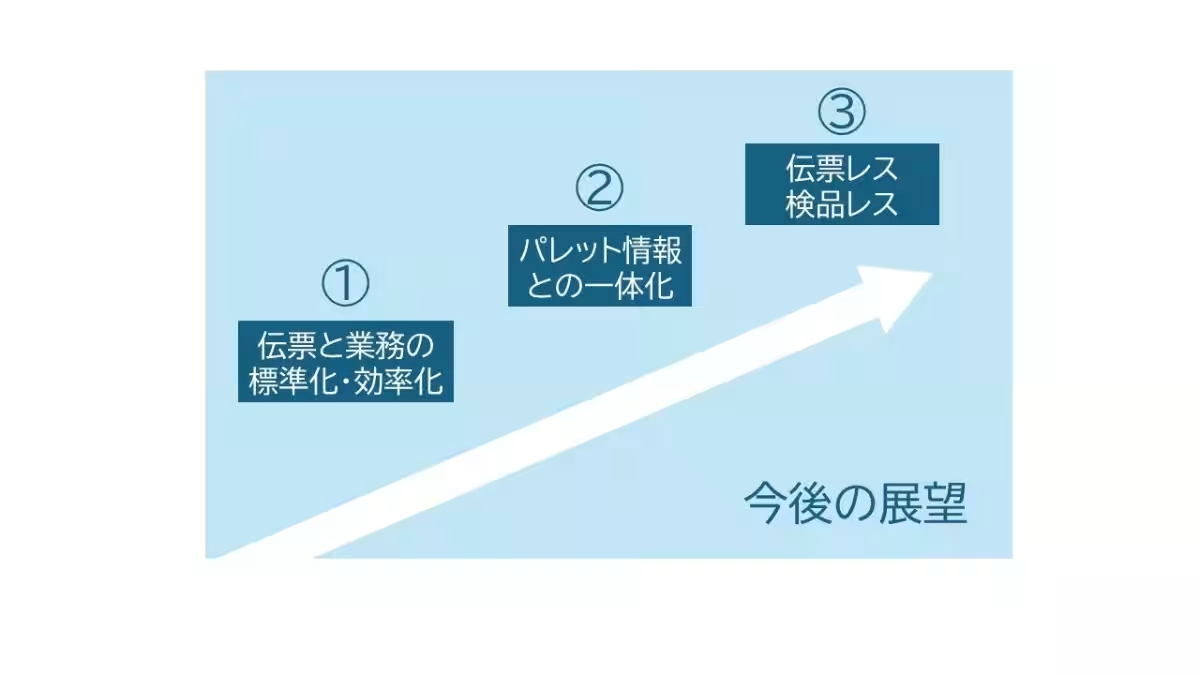

Future Outlook

While the current focus of implementing DD Plus revolves around its delivery slip issuance capabilities, the future development plan aims for further productivity increases through several strategic steps:

1. Standardization and Labor Saving through Collaboration with Other Shippers: Atago Warehouse manages logistics operations for numerous shippers, including Fumakilla. This initiative could serve as a springboard for horizontally expanding similar system integrations with other parties, ultimately seeking to standardize delivery slip processing and reduce the operational burdens on logistics providers.

2. One-stop Processing for Pallet Handling: The objective is to handle both delivery slip data and pallet information simultaneously, allowing for seamless processing of pallet receipts during the incoming procedures.

3. Elimination of Paper Slips and Inspection Processes: The long-term vision includes completely eliminating paper delivery slips through full electronic execution and establishing a system that utilizes shipment data (ASN) for inspections, ultimately streamlining operations further.

Fumakilla and its partners are determined to strengthen their collaboration and contribute to solving overarching challenges within the logistics industry, aiming to establish a sustainable supply chain.

Comments from the Companies Involved

- - Fumakilla Co., Ltd.: "The introduction of DD Plus marks a crucial first step in our logistics digital transformation journey. We look forward to collaborating with Atago Warehouse and other partner companies to further enhance our efficiency."

- - Atago Warehouse Co., Ltd.: "With the system integration of DD Plus, we can now automate processing not only for Fumakilla but also for other manufacturers utilizing our center. We aim to promote this setup across other manufacturers, alleviating their operational burdens while standardizing and enhancing efficiency in our operations."

- - TSUNAGUTE, Inc.: "We are pleased to contribute to the logistics sector's efficiency enhancement through this project leveraging our accumulated knowledge in logistics system implementation. We will continue to play a crucial role in connecting various systems and processes to enhance value."

- - Japan Pallet Rental Co., Ltd.: "Currently, DD Plus is primarily used for its delivery slip generation features; however, its strength lies in its ability to smoothly facilitate hybrid operations catering to both paper and electronic environments. We aim to provide valuable benefits tailored for our clients based on this advantage."

Company Overview

- - Fumakilla Co., Ltd. (URL: fumakilla.co.jp)

- - Atago Warehouse Co., Ltd. (URL: atg-logi.co.jp)

- - TSUNAGUTE, Inc. (URL: tsunagute.co.jp)

- - Japan Pallet Rental Co., Ltd. (URL: jpr.co.jp)

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.