Revolutionizing Construction with DUMPLUS: The Future of Dump Truck Data Management

DUMPLUS: A New Era in Dump Truck Management

Introduction

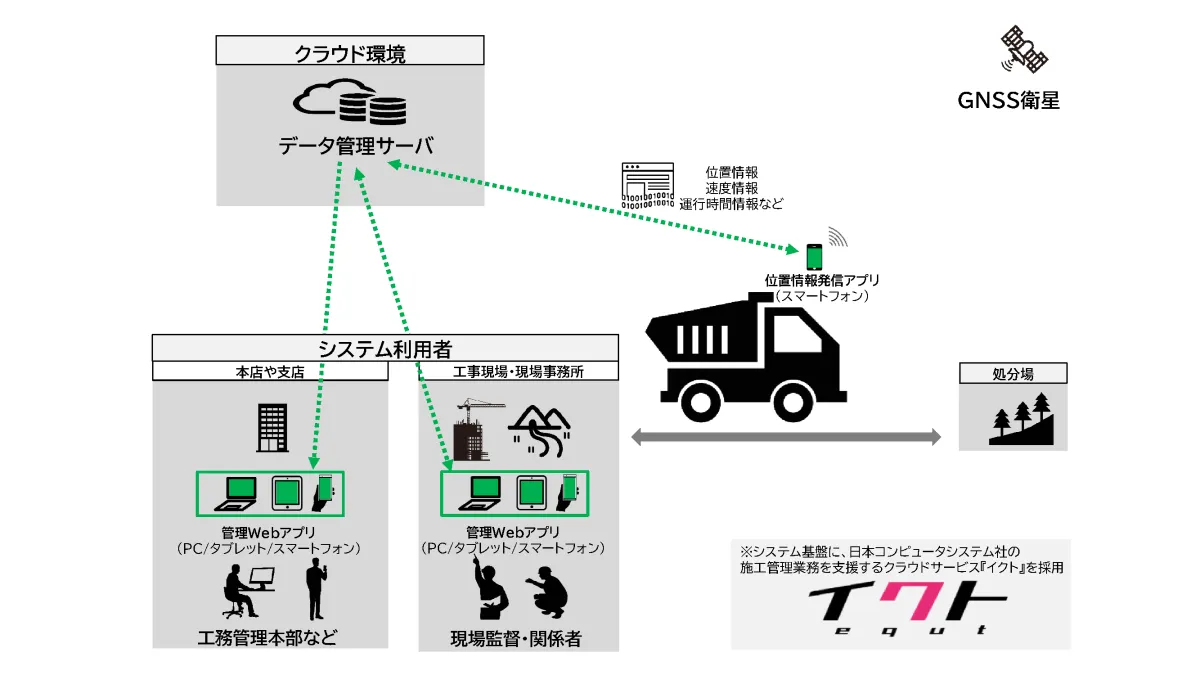

In a significant advancement for the construction industry, Konoike Corporation, headquartered in Osaka, has partnered with Nippon Computer Systems (NCS) based in Tokyo to co-develop DUMPLUS, a data management system tailored for dump trucks. Launched with the aim of enhancing productivity on construction sites, DUMPLUS reimagines traditional practices with the philosophy of transitioning from "experience and intuition" to "data and strategy."

Background Behind DUMPLUS

To cater to the growing need for real-time tracking of dump truck operations, DUMPLUS was developed as a robust solution to streamline logistics management on construction sites. By harnessing the data accumulated through the system, managers can implement effective vehicle planning and re-evaluate processes, thereby drastically simplifying on-site operations and alleviating workloads for administrators. With features such as planning for transportation of soil, visualization of operational status, and performance management capabilities, DUMPLUS is set to maximize productivity and asset efficiency on construction sites.

Key Features of DUMPLUS

To meet the specific demands of construction sites and promote efficiency, DUMPLUS comes equipped with a variety of distinguished functionalities:

1. AI-Powered Transportation Planning: Utilizing artificial intelligence, DUMPLUS proposes optimized transport plans by analyzing external data, including weather conditions and site-specific metrics. This automation allows even less experienced managers to utilize the system effectively.

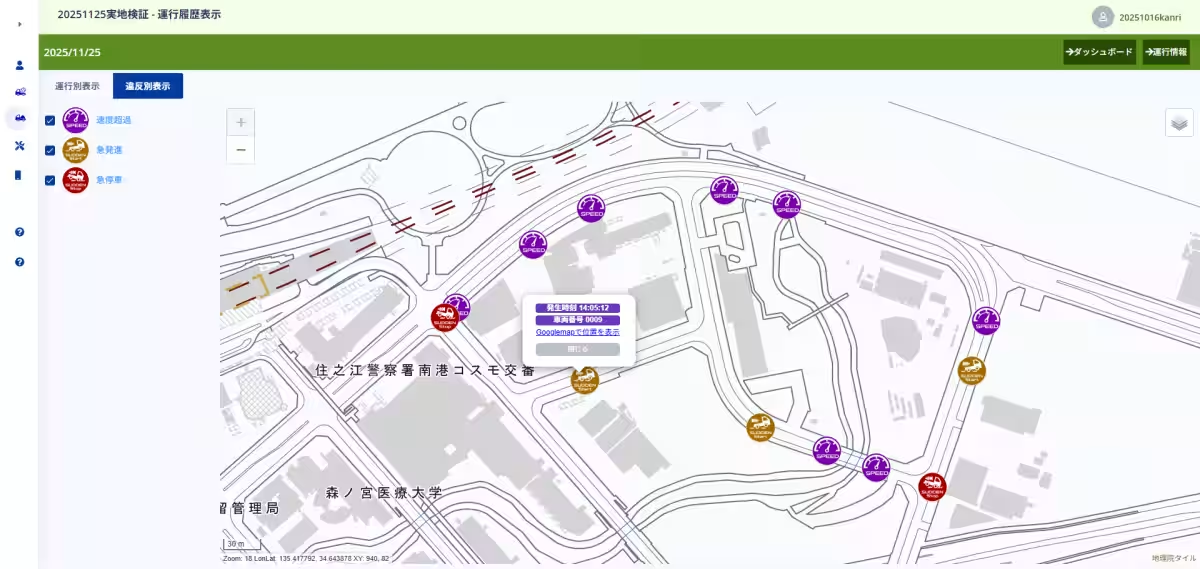

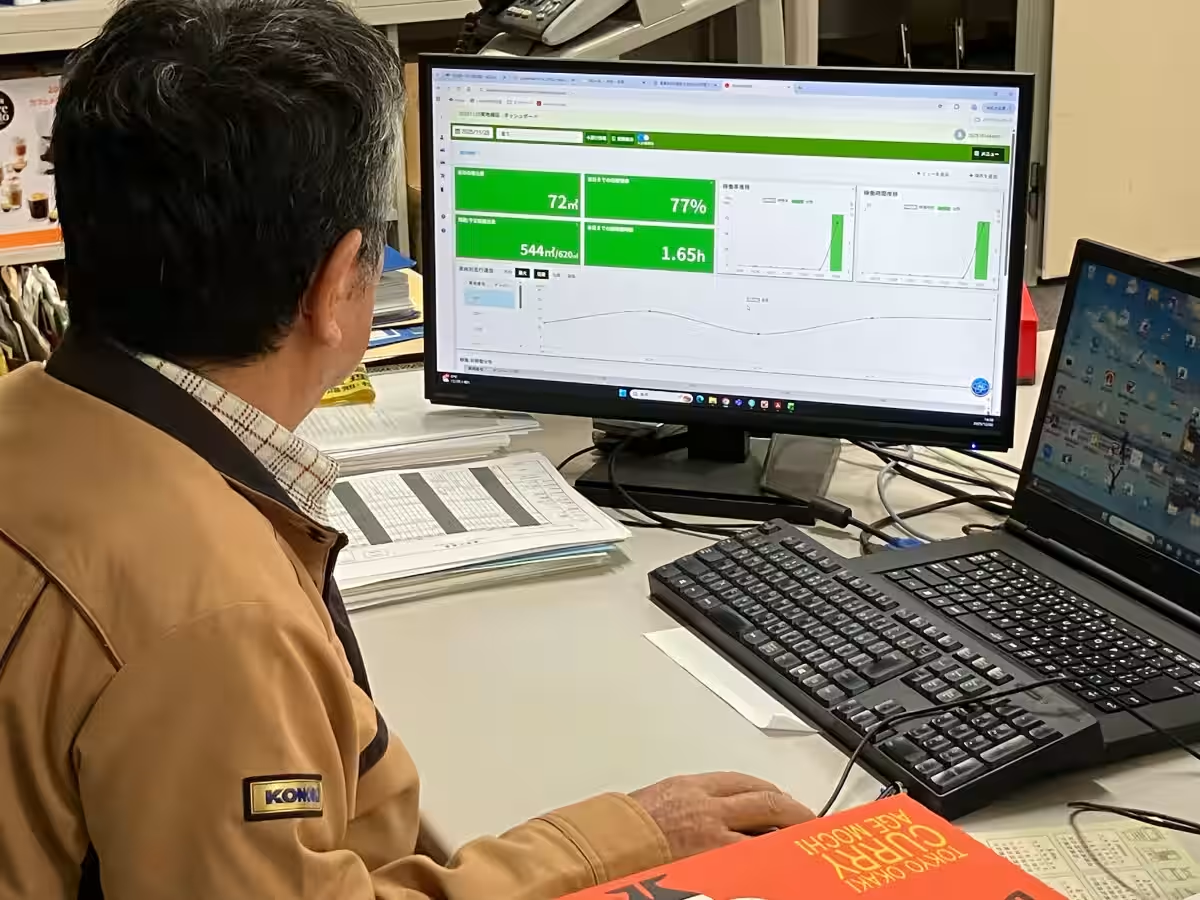

2. Real-Time Operational Insights: The system provides a detailed visualization of operational metrics such as utilization rates, traveling speeds, and idle times, empowering managers with insights necessary for optimal resource allocation.

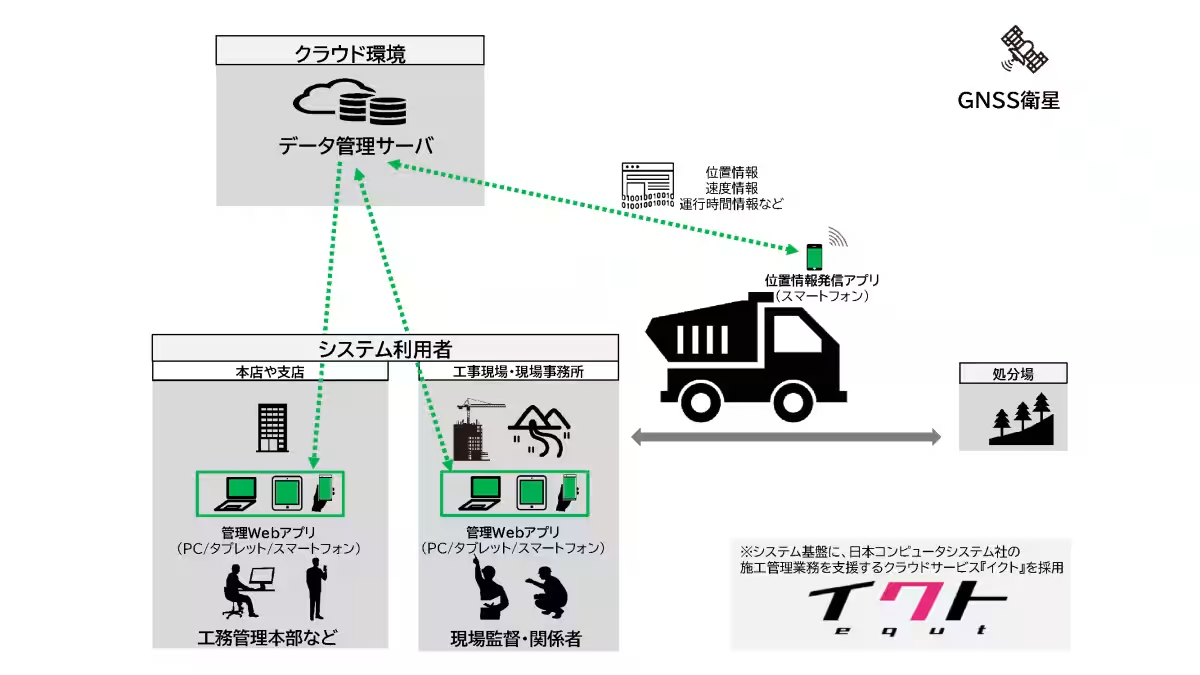

3. Geographical Mapping of Operations: With a mapping feature that highlights travel routes and speed violations, those in charge can ensure compliance and safety during operations. Additionally, operators can access the driving history and system management screens, aiding in accountability and monitoring.

These features are designed to operationalize real-time process improvements, enhancing the efficiency of earthmoving tasks and associated inspection activities while ensuring noticeable productivity gains.

Forward-Looking Developments

From December 2025, Konoike and NCS will initiate in-house operational trials of DUMPLUS, allowing for the accumulation and assessment of real-world construction data. As they conduct practical tests in various fields, there will be ongoing efforts to elevate both functionality and user experience, making DUMPLUS an increasingly practical solution.

Starting in 2026, once the system has been refined through practical application, Konoike aims to offer DUMPLUS externally, sharing this revolutionary management tool with other companies. Ultimately, the initiative seeks to contribute to the digital transformation throughout the construction industry, thereby enhancing productivity sector-wide.

Conclusion

In summary, DUMPLUS stands at the forefront of marine construction technology as it merges data analytics with tradition. This powerful tool not only promises improved operational oversight but also supports the industry's transition to smarter, data-driven practices, reshaping the future of construction management.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.