Expansion of High-Performance Phenolic Resin Materials for Automotive Applications

Introduction

Sumitomo Bakelite Co., Ltd., headquartered in Shinagawa, Tokyo, is expanding its series of phenolic resin molding materials known as "Sumicon® PM-5700." This series, which possesses high lubricity and thermal resistance, is increasingly being used for bearings in electric pumps as the automotive industry shifts towards electrification.

Background of Development

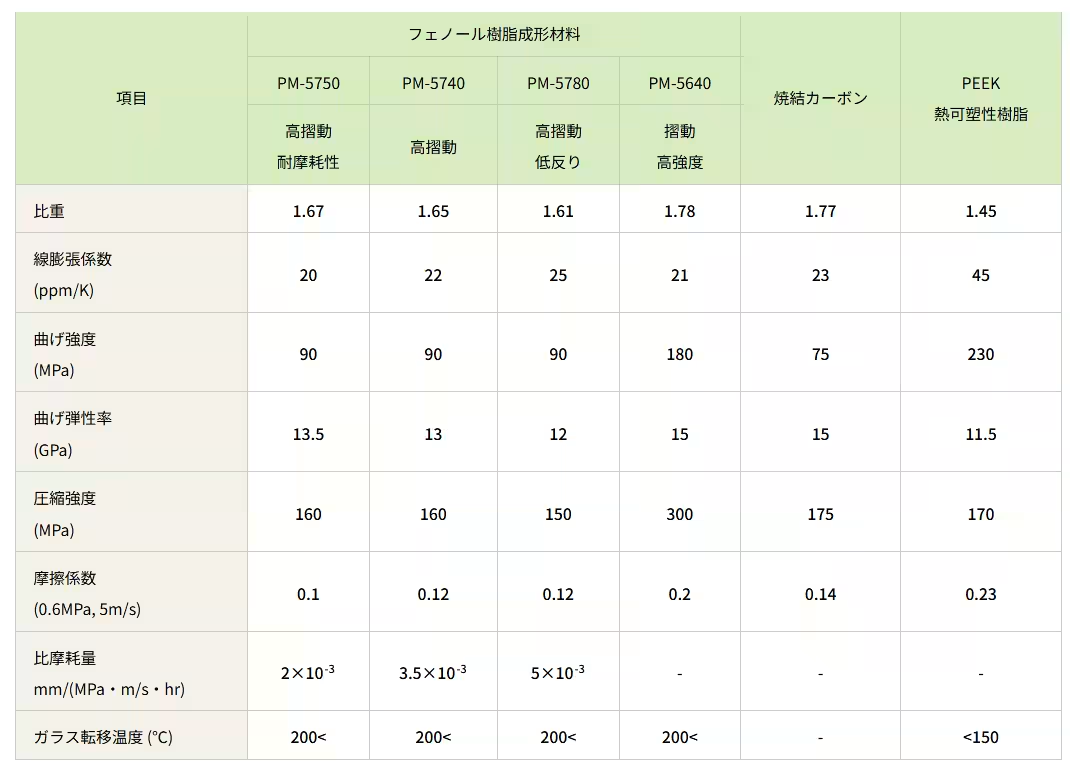

The advancement in electric vehicles is driving a need for enhanced functionality, cost optimization, and a reduction in CO2 emissions of in-vehicle electric pumps, including electric water pumps (EWP) and electric oil pumps. Components like bearings in EWPs, which are essential for cooling batteries and heat-emitting electronic parts, traditionally use expensive materials like sintered carbon and PEEK (polyether ether ketone), which contain PTFE, a type of PFAS. These materials often have high carbon footprints during production and require complex machining, leading to increased costs. Consequently, pump manufacturers are demanding high durability for bearings and are actively exploring new material alternatives to meet the high output of pumps.

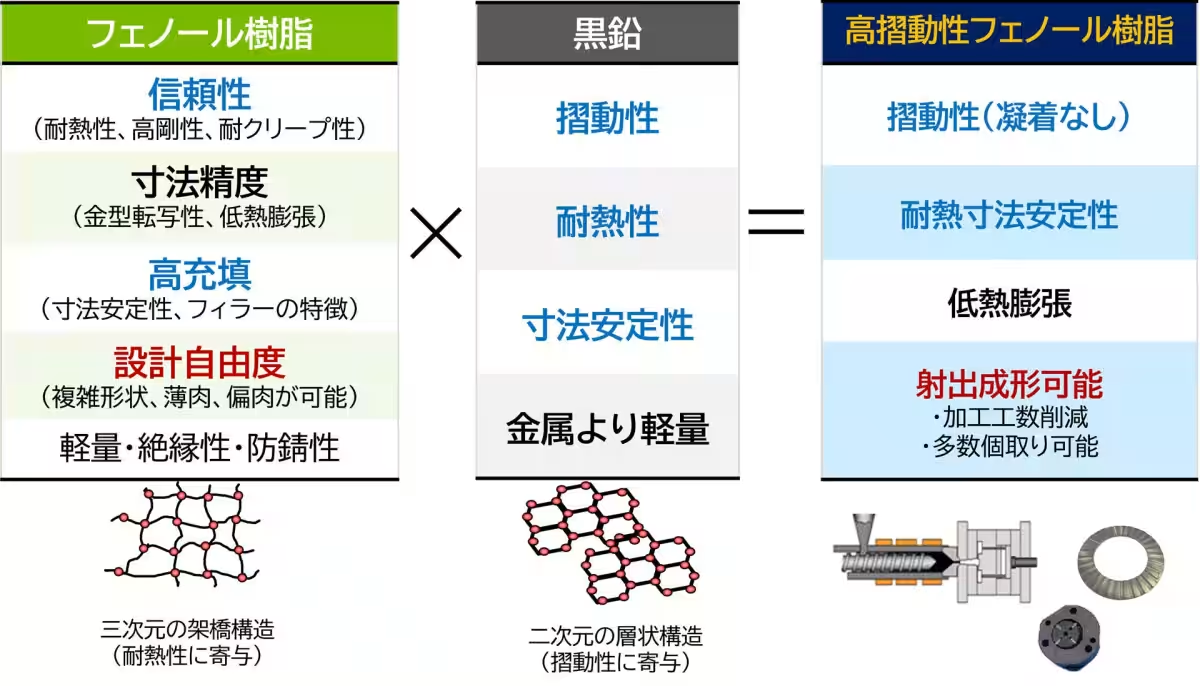

Overview of Sumicon® PM-5700 Series

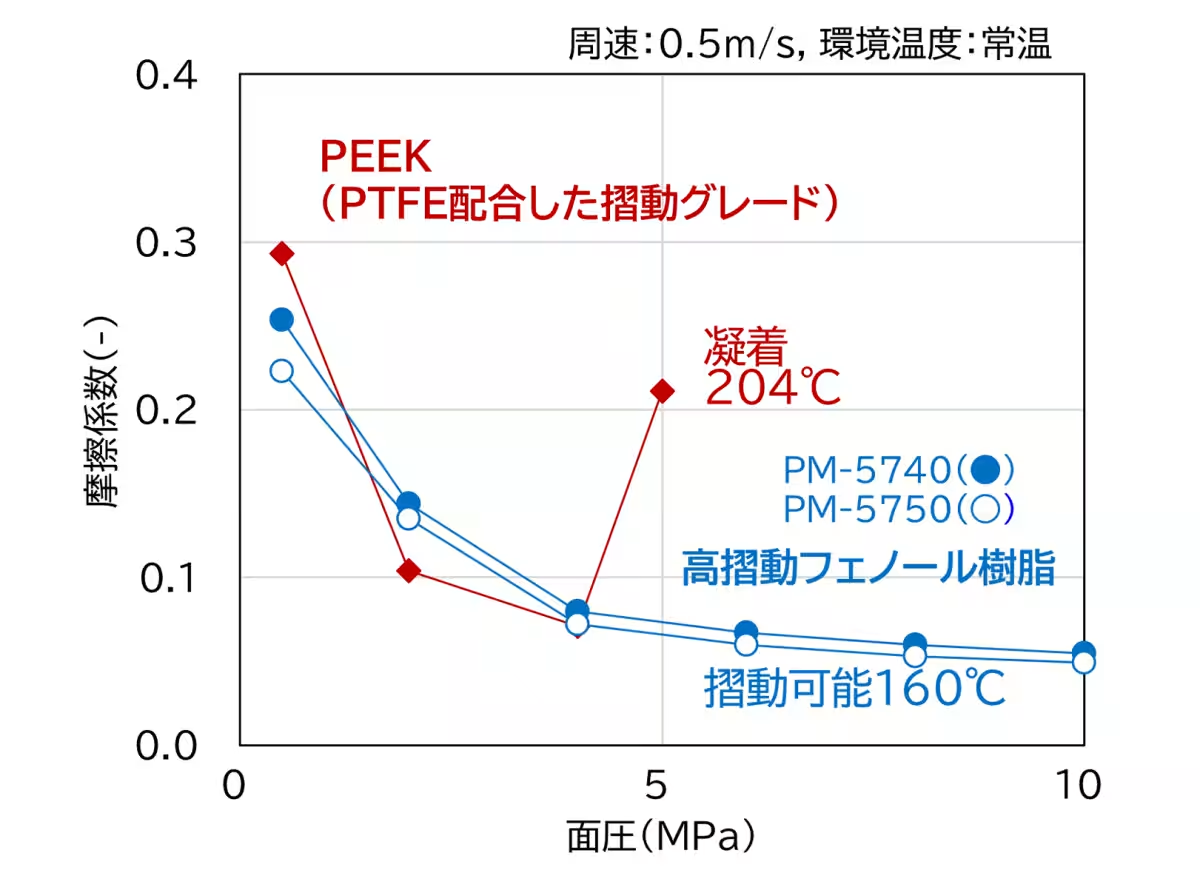

The Sumicon® PM-5700 series features phenolic resin that is filled with graphite to create an ideal combination of high resistivity to heat and excellent sliding properties. Thanks to a unique formulation, this series achieves high thermal resistance without melting or fusing during operation. It is compatible with injection molding processes, allowing for the creation of thin-walled or unevenly thick parts due to its low viscosity at the melting stage. This flexibility in design facilitates a wider array of potential applications.

Product Details

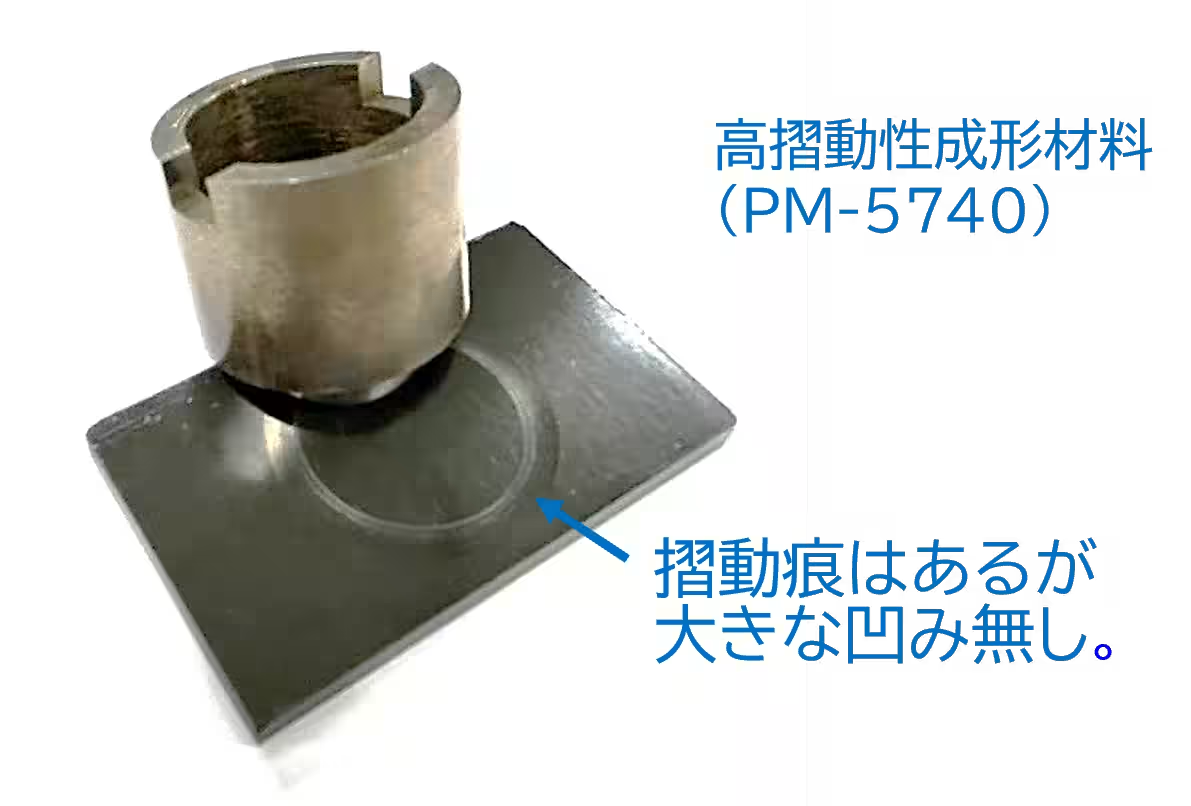

The company has built a solid sales record of the Sumicon® PM-5700 series in applications such as bearings for EWPs. A new addition to this lineup, PM-5750, aims to improve wear resistance and thermal dimensional stability, responding to the growing demand for enhanced lubricating properties in various applications.

Future Plans

By enhancing its sales of high-lubricity, high-temperature phenolic resin materials, Sumitomo Bakelite aims to grasp customer needs while leveraging its strengths in resin development to advance the creation of even more efficient products for high-temperature and high-load applications. The company has set an ambitious target to achieve sales of ¥2 billion in its sliding molding materials division by the fiscal year 2030.

Key Features of the Product

These materials exhibit high wear resistance, making them suitable for sliding parts used in pumps and other machinery. Additionally, being thermosetting resins, they avoid melting and sticking due to friction heat. Furthermore, they demonstrate minimal dimensional changes in high-temperature environments and when submerged in cooling water.

Environmental Impact Reduction

In recent years, there has been an increasing demand for environmental considerations, including moves towards carbon neutrality. In this context, the Sumicon® PM-5700 series significantly reduces energy consumption during production compared to sintered carbon, contributing to lowering environmental impact. According to company projections, the carbon emissions of these products can be reduced to less than one-tenth of that of sintered carbon, thus significantly contributing to efforts towards carbon neutrality.

Conclusion

Sumitomo Bakelite Co., Ltd. continues to evolve its product offerings in the realm of materials, aligning with growing market demands and environmental challenges. By focusing on high-performance solutions, the company is committed to paving the way for a more sustainable automotive future.

For inquiries, contact Sumitomo Bakelite's Materials Solutions Division at Polymer Sales, Tokyo, Japan. Telephone: 03-5462-4241, or visit Inquiry Form.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.