Manufacturing Industry Struggles with Digitalization Amid High Awareness of the 2025 Cliff

Manufacturing Industry Struggles with Digitalization Amid High Awareness of the 2025 Cliff

In a recent study conducted by Shimtops, a leading provider of on-site reporting systems in Japan, it was revealed that 69.6% of manufacturing industries continue to manage their on-site reports using paper or Excel. This figure has increased by 5.9 percentage points since 2022, indicating a troubling tendency to revert to analog methods despite technological advancements and the widespread acknowledgment of looming challenges, such as the so-called '2025 Cliff.'

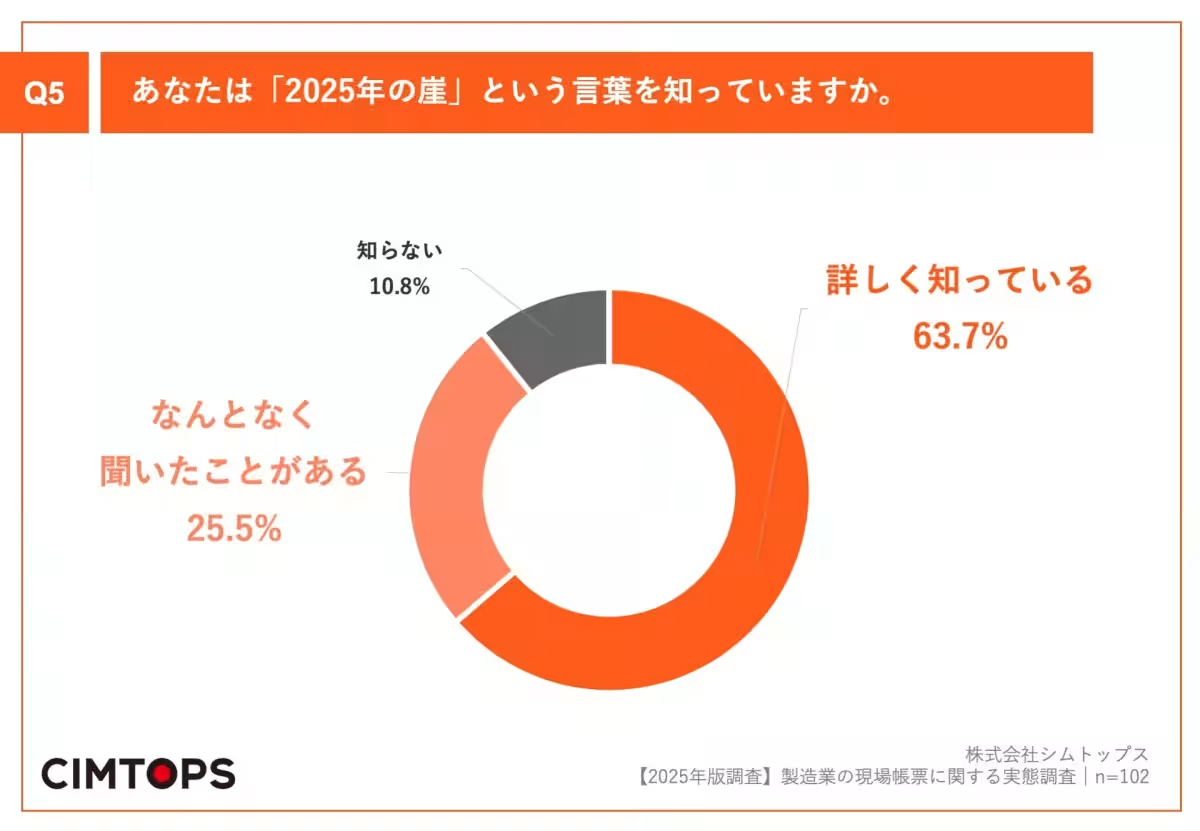

The study targeted 102 manufacturing professionals managing on-site reports, focusing specifically on companies with more than 50 employees. While the awareness of the 2025 Cliff is notably high, with 89.2% of respondents recognizing it, the actual integration of digital practices within these organizations appears to lag.

Insights from the Survey

Predominance of Paper and Excel in Management Practices

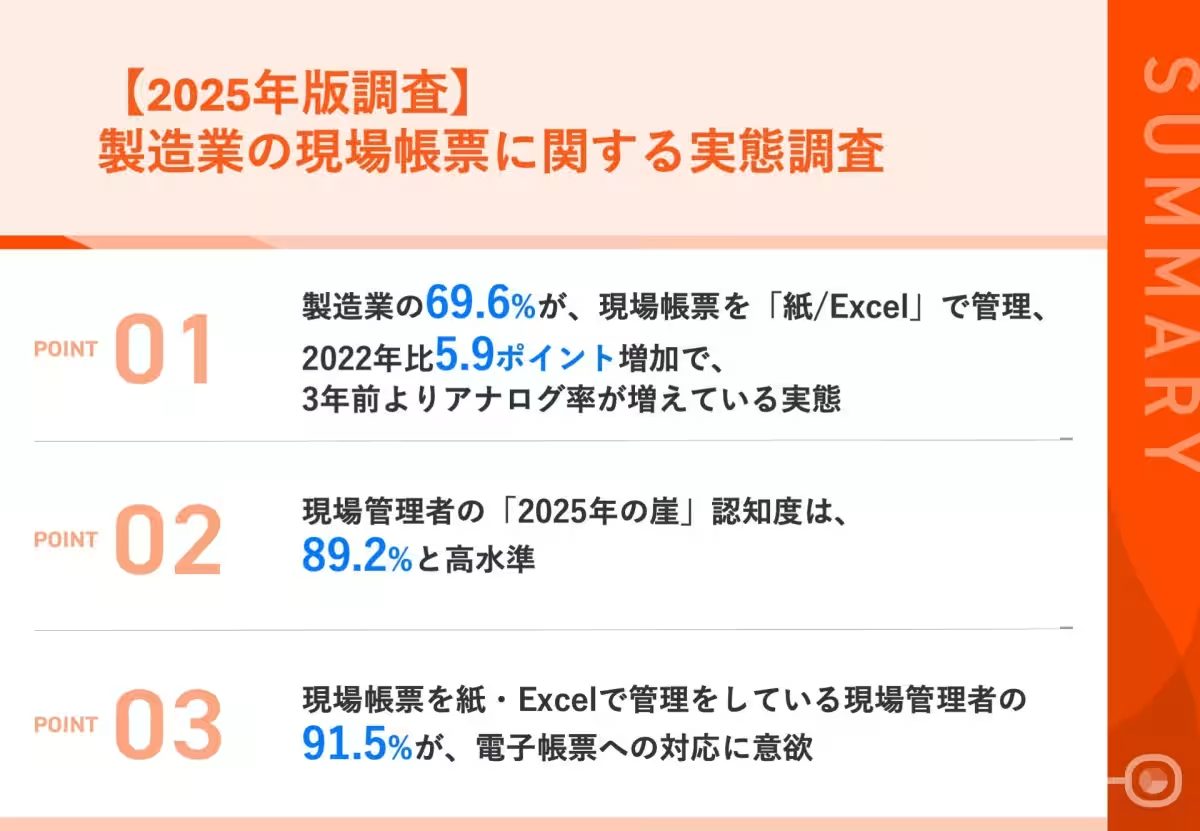

The survey posed the question: “How does your workplace primarily manage on-site reports?” The responses revealed that 20.6% of participants relied on paper, and 49.0% used Excel, leading to the overall percentage of organizations managing reports with these traditional methods to total 69.6%. Such a reliance suggests that despite possible technological solutions available, many are hesitant to shift from familiar processes, resulting in a stagnation of digital transformation efforts.

Reasons Behind Continued Use of Paper Workflows

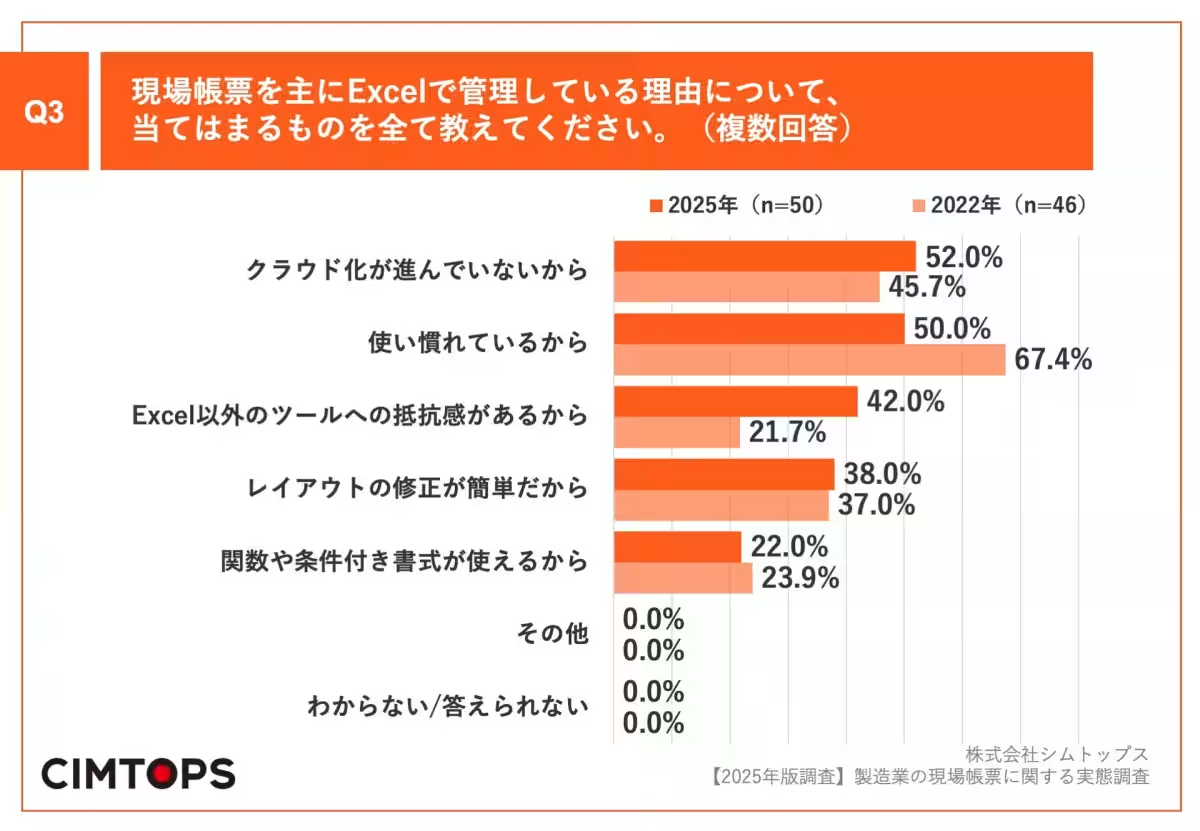

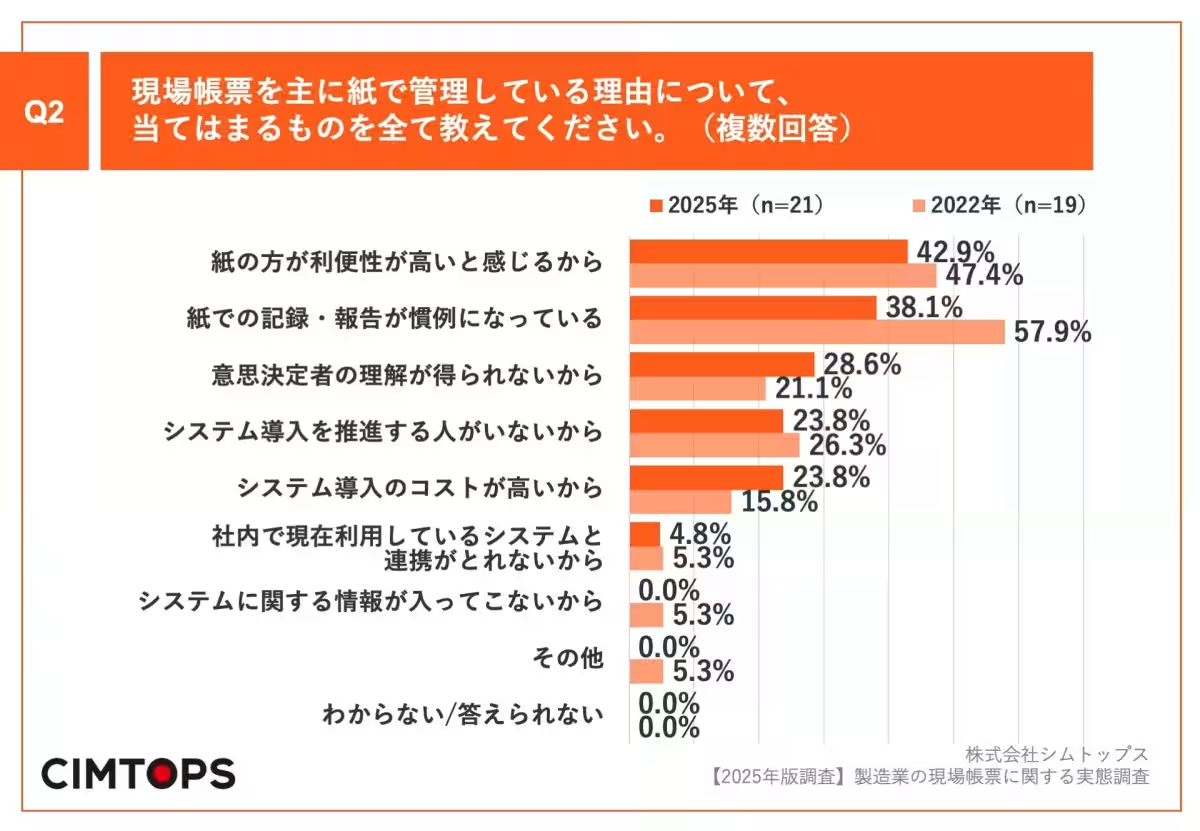

When asked why they prefer using paper for report management, some reasons provided included convenience (42.9%), customary practices (38.1%), and insufficient buy-in from decision-makers (28.6%). Similarly, for those using Excel, concerns were also noted over the lack of cloud solutions (52.0%) and a general familiarity with Excel (50.0%). This reliance on traditional methods might stem from limited IT investment, especially within medium-sized enterprises where cautious approaches to technological adoption are common.

Recognition of Challenges

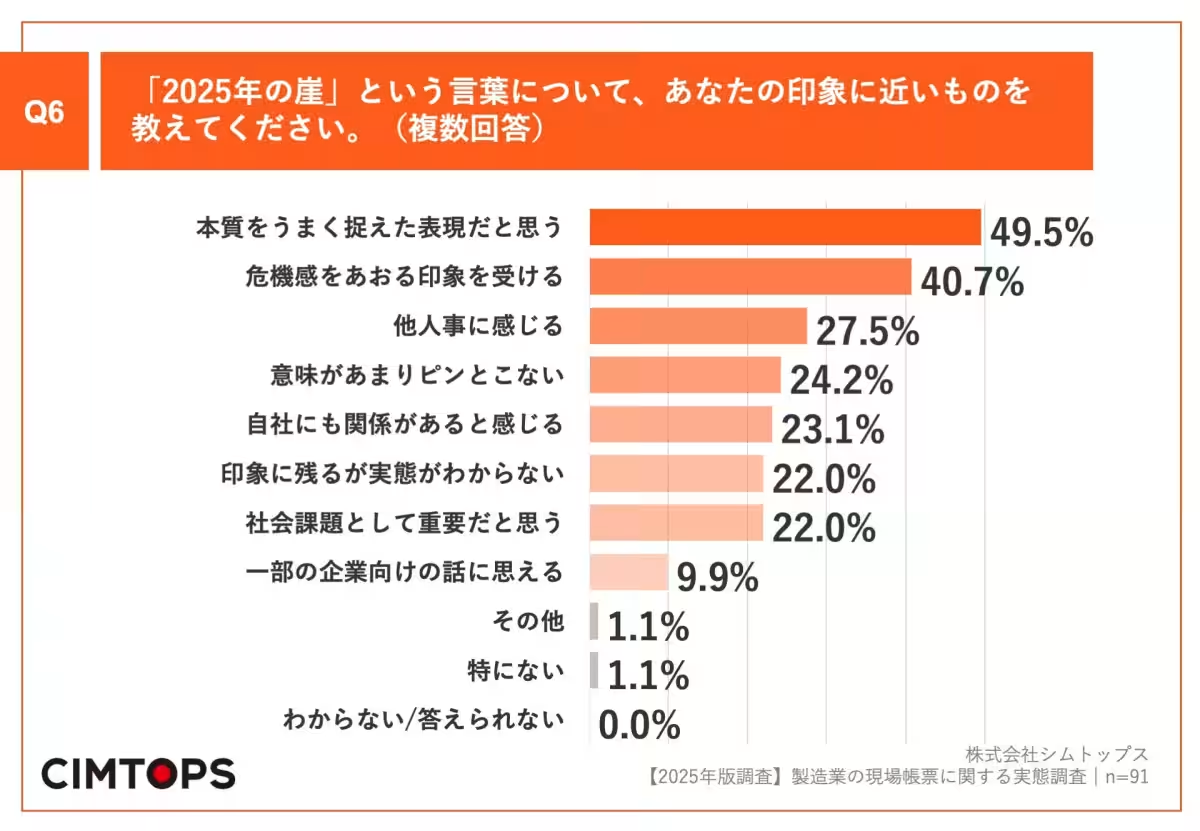

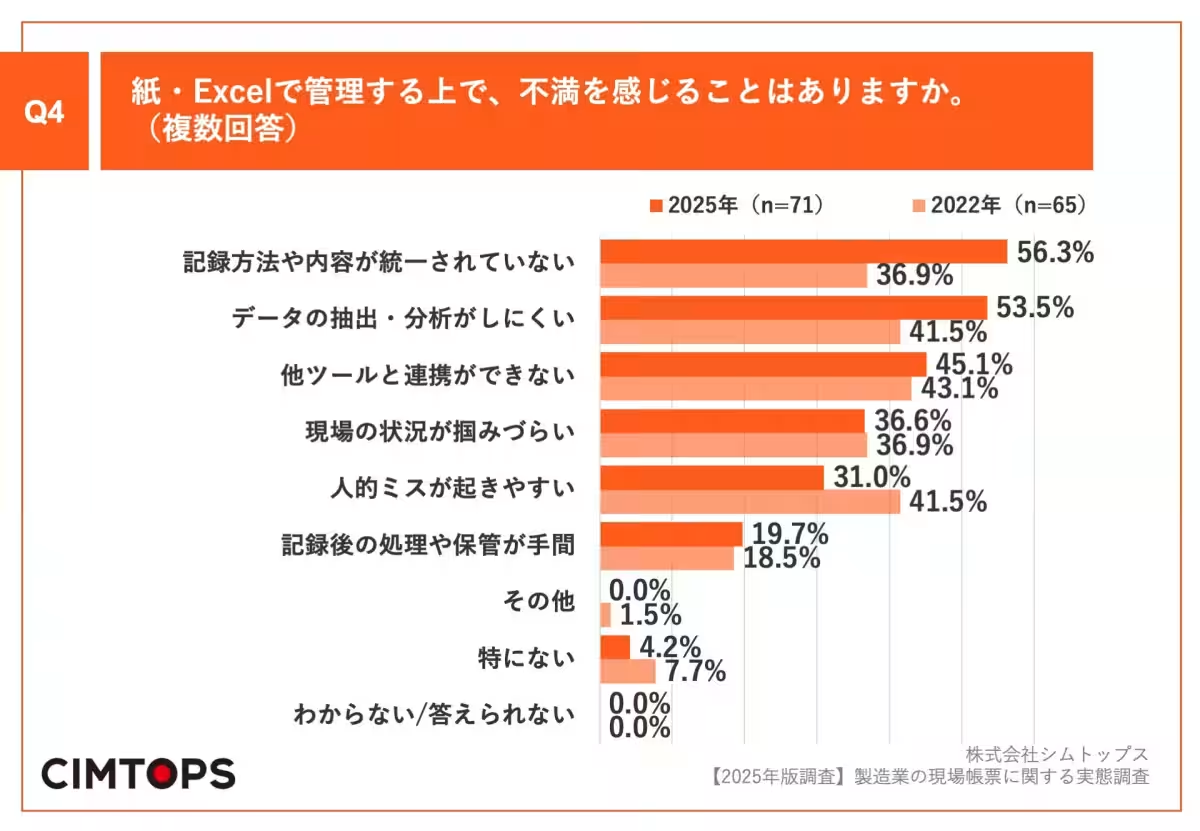

Despite a significant awareness of the digital competency gap highlighted by the 2025 Cliff, participants reported substantial dissatisfaction with traditional reporting methods. A striking 56.3% stated that their recording methods were inconsistent, while 53.5% noted difficulties in data extraction and analysis. This inconsistency exacerbates operational inefficiencies and hinders the expected benefits of digital transformation processes.

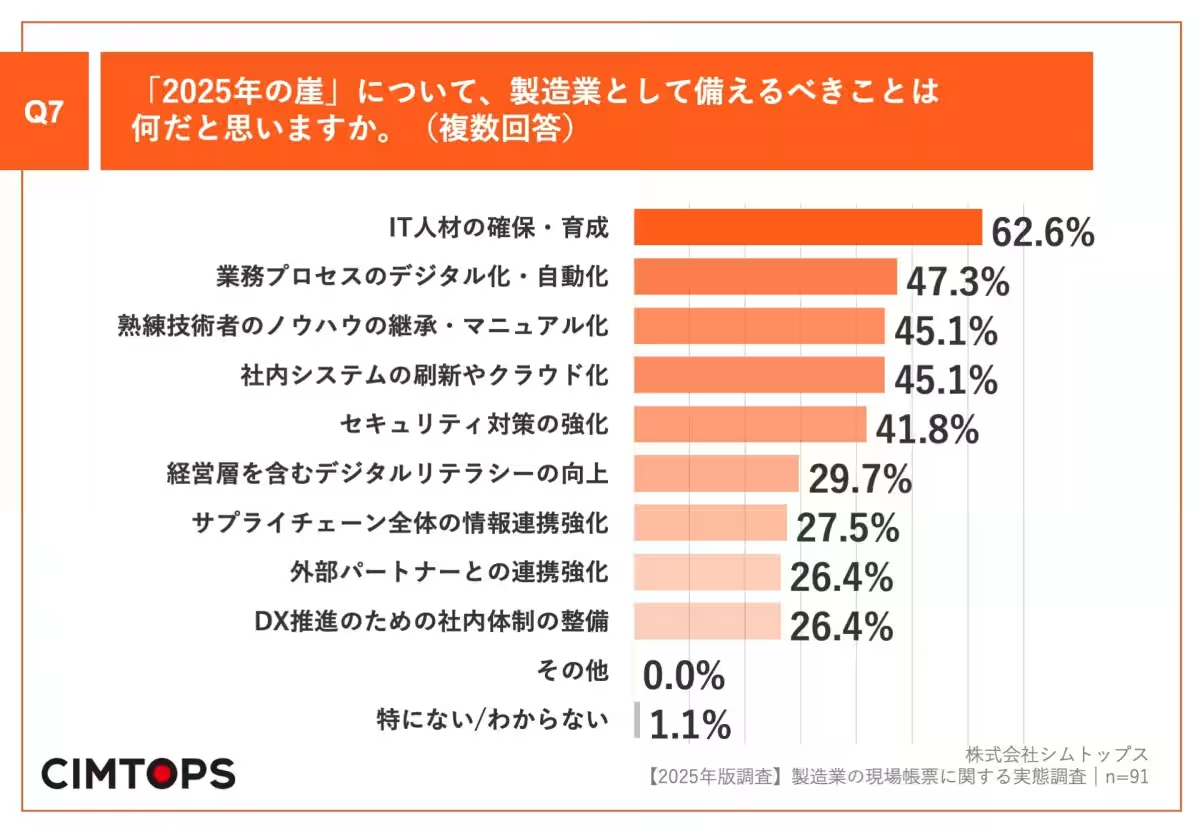

Capability Building for the Future

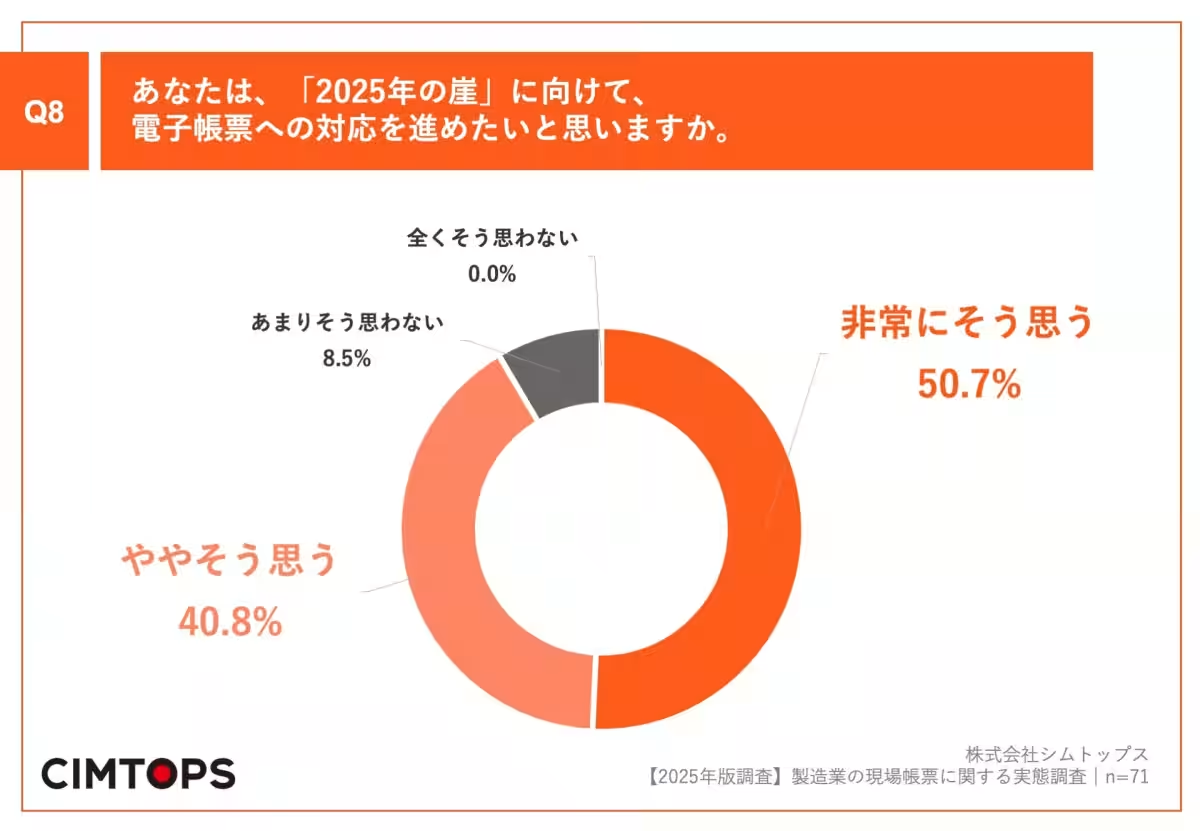

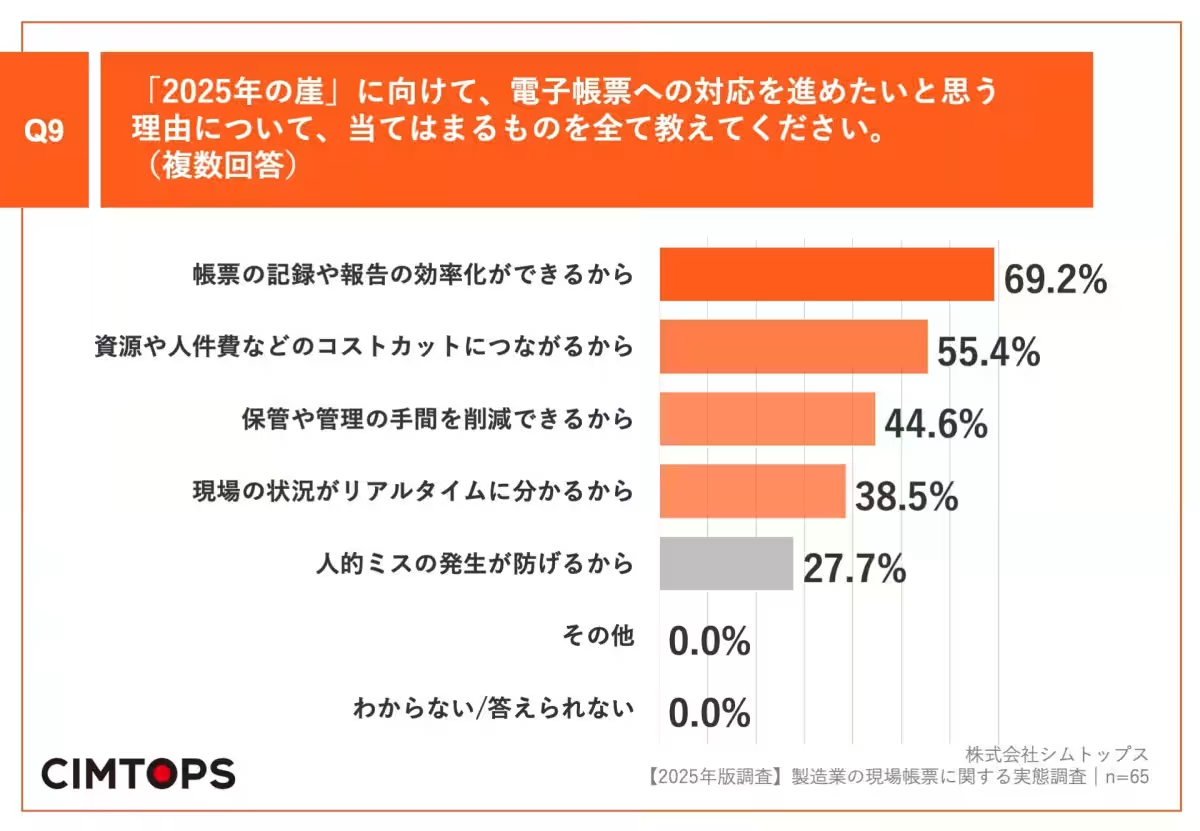

When discussing preparations for the 2025 Cliff, 62.6% of professionals emphasized the need for IT personnel development, while nearly half recognized the importance of digitalizing and automating business processes. Notably, 91.5% expressed a strong desire to move towards electronic reporting systems, with many citing efficiency in reporting as a key benefit.

A Call for Action in Digital Transformation

The data presents a paradox: while awareness and the desire for improvement are evident, the manufacturing industry struggles to implement effective digital processes adequately. The ongoing use of paper and Excel reflects an industry-wide reluctance to embrace change, regardless of the pressing need for modernization.

Moving forward, organizations must develop robust strategies that not only introduce digital tools but also ensure their integration into daily practices. It is crucial to mitigate resistance at the ground level by providing adequate training and continuously demonstrating the value of digital systems to stakeholders.

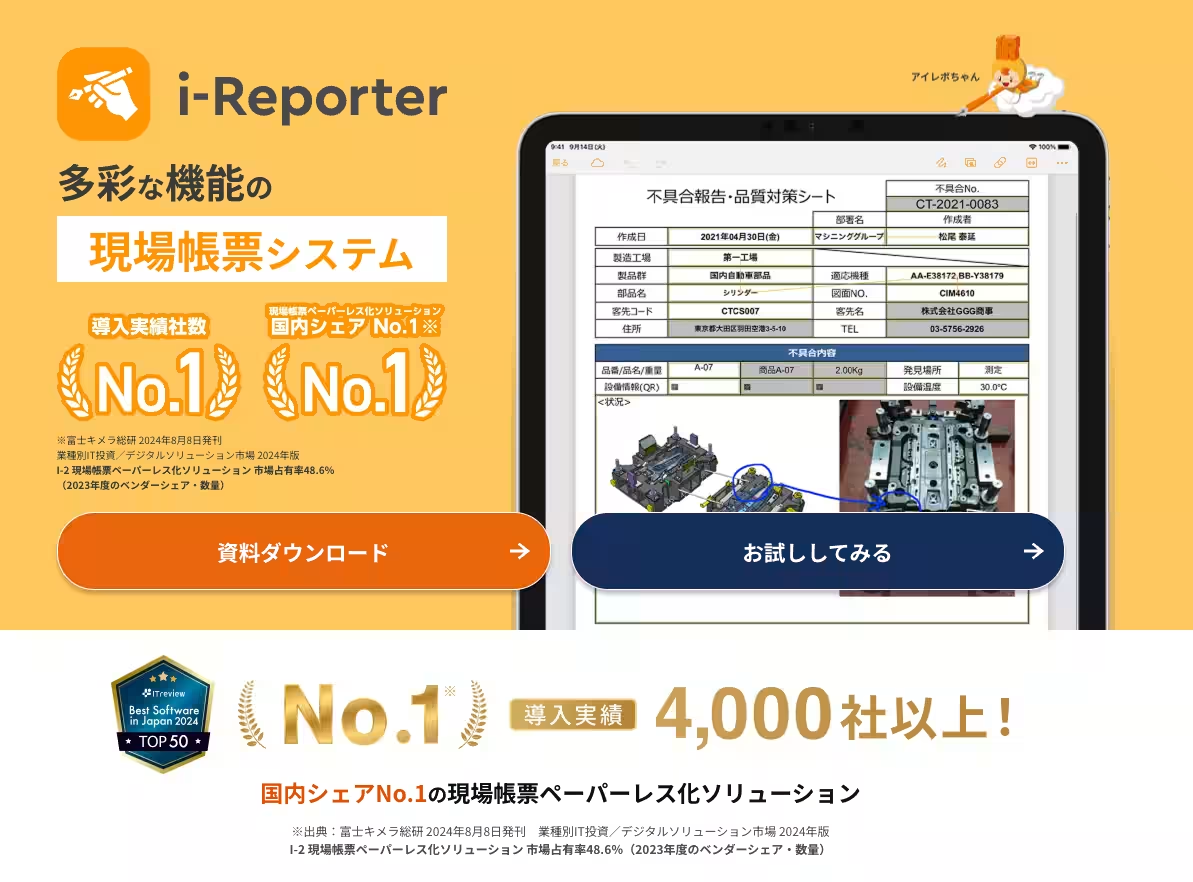

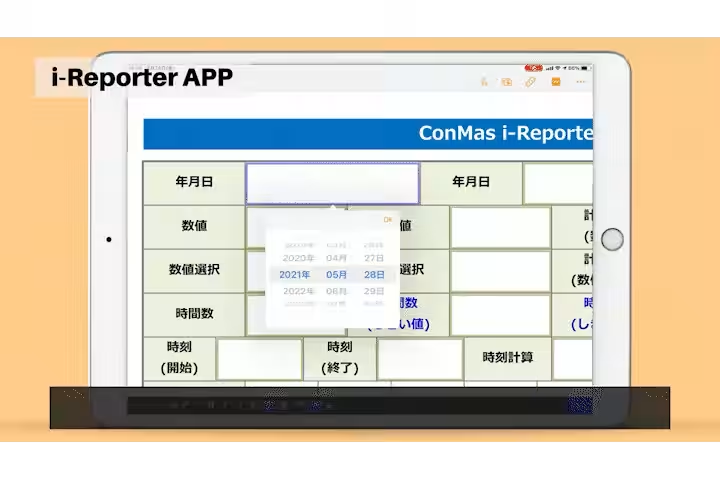

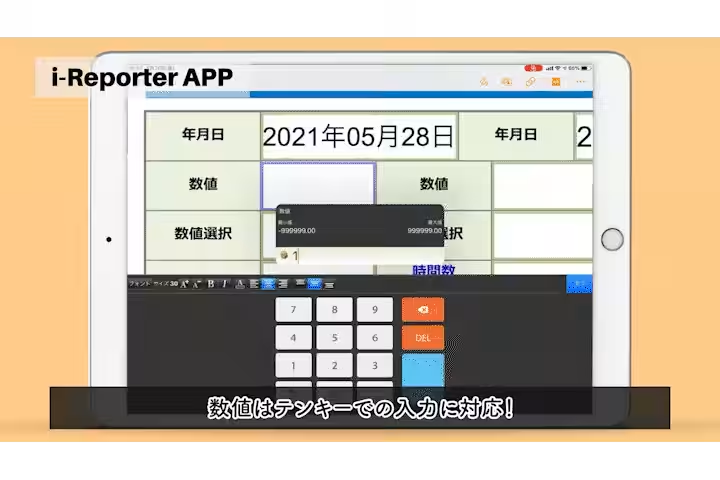

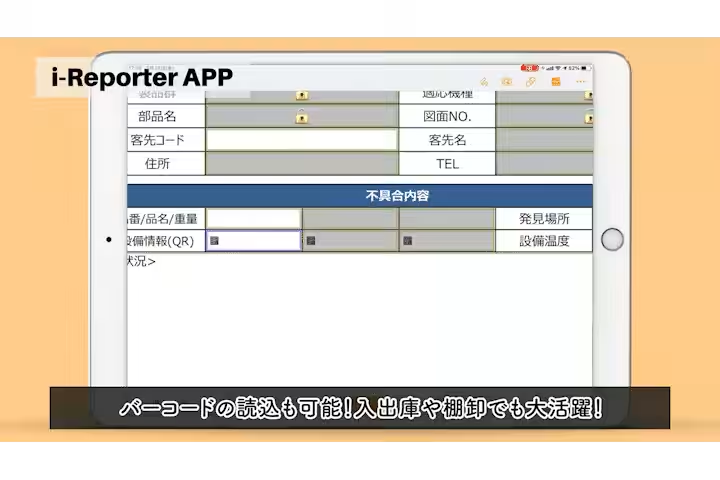

Additionally, Shimtops highlights its flagship product, i-Reporter, designed to facilitate the transition to electronic reporting. By simplifying the reporting processes seamlessly, i-Reporter aims to eliminate resistance from employees accustomed to traditional methods.

Conclusion

This survey underscores significant challenges facing the manufacturing industry in Japan concerning digital transformation. Despite a high level of awareness regarding the 2025 Cliff, the persistence of analog management practices raises alarms about the industry's readiness to adapt. As organizations gear up for the future, addressing training, strategy development, and employee engagement will be crucial for realizing the potential benefits of digital technologies. The industry's success in navigating this critical transition may very well depend on how effectively they can convert enthusiasm and awareness into actionable change.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.