Mujin Expands AGV Lineup to Meet Diverse Transport Needs

Mujin Enhances AGV Lineup to Optimize Automation

Mujin, a leader in automation technology, has introduced two new models to its MujinAGV lineup, aimed at addressing a variety of transport needs in manufacturing and logistics. The newly launched models include an 800kg safety model and a 1,500kg capable version. These advancements come at a time when industries face challenges such as fluctuating demand, labor shortages, and the necessity for safety enhancements.

Adapting to Industry Challenges

As the manufacturing and logistics sectors evolve, the demand for robust automation solutions has surged. Companies strive to maintain uninterrupted production while coping with the aforementioned complexities. Traditional manual handling practices have made it difficult to balance productivity with flexibility, particularly in transport processes. Mujin aims to tackle these challenges through holistic, interconnected autonomous automation rather than piecemeal mechanization. Central to their strategy are the MujinOS platform for integrated automation and the MujinAGV mobile robots.

New Models That Broaden Automation Possibilities

With the introduction of these two new models, MujinAGV now has the capability to cater to a wider range of operational environments, safety requirements, and layouts.

800kg Safety Model

This model not only meets standard functional demands but has also incorporated enhanced safety features compliant with industrial safety standards (ISO3691-4). This upgrade ensures a high level of security in environments where human-machine collaboration is essential, facilitating flexible transportation in areas like picking and assembly lines.

1,500kg Model

Designed for heavy-duty applications, this new model surpasses the existing 800kg and 1,000kg versions. It's particularly suited for transporting large pallets and heavy components like batteries, further expanding opportunities for automating warehouse and production line operations.

Why MujinAGV is the Preferred Choice

With over 1,500 units deployed, MujinAGV has established a strong foothold in the industry, especially among domestic car manufacturers and automotive parts suppliers. The platform has demonstrated operational reliability across diverse environments, leading to a repeat business rate of approximately 70% among clients. Mujin's dedicated teams provide comprehensive support, from initial specifications and design to ongoing maintenance, including operational stability enhancements such as mapping and maintenance assistance. Additionally, Mujin bolsters its technical support with dedicated teams in Tokyo and the Aichi-Mikawa region.

Real-world Applications

MujinAGV is already making waves in the industry. For example:

- - Toyota Boshoku Corporation utilizes it for palletizing tasks, enhancing storage and transportation through digital transformation.

- - Sangau Co., Ltd. has revamped its factory logistics with an unmanned product warehouse, accelerating cost reductions alongside digital transformation.

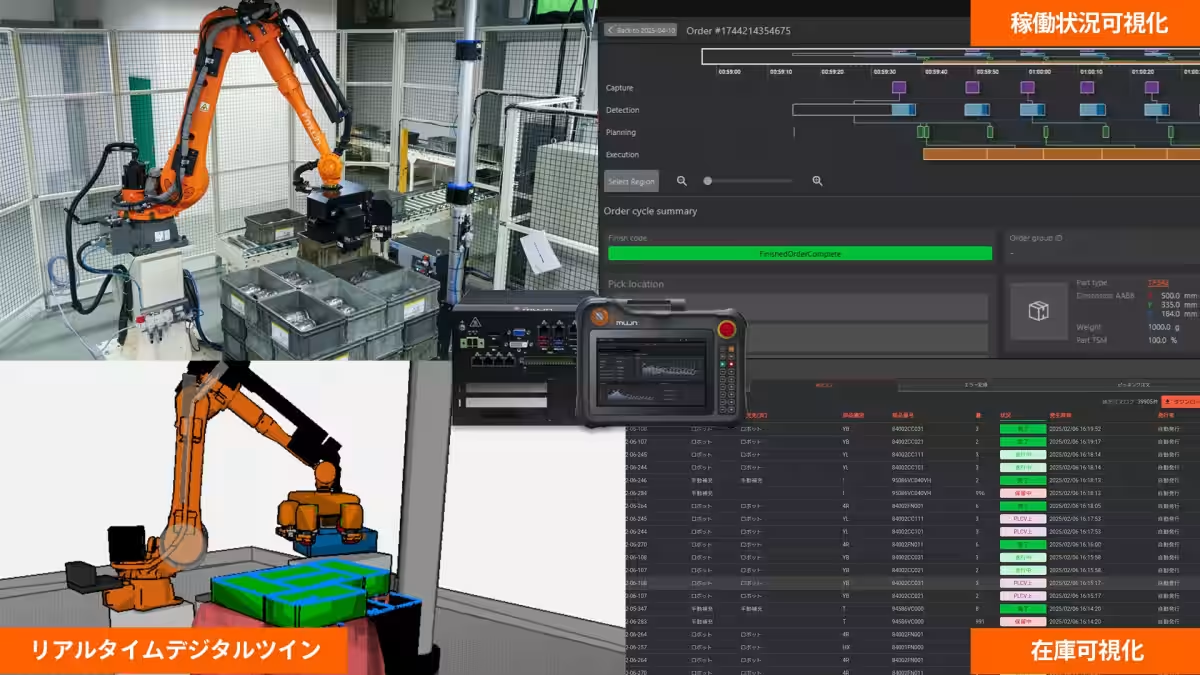

MujinOS: Enabling Comprehensive Automation

MujinOS serves as a robust integrated automation platform. It allows seamless operation of various devices, from a single AGV to an entire line of sorting robots. By not limiting itself to partial optimization, MujinOS promotes

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.