The Rise of AI in Manufacturing: Enhancing Productivity and Mitigating Risks

The Rise of AI in Manufacturing: Enhancing Productivity and Mitigating Risks

In the contemporary landscape of manufacturing, the integration of Artificial Intelligence (AI) technologies is reshaping the industry in dynamic ways. According to a recent study conducted by CABDI Corporation, a Tokyo-based startup focusing on AI-driven solutions, approximately 60% of manufacturing professionals have reported enhanced productivity through the application of AI tools.

The Context of AI Adoption in Manufacturing

As Japan's government seeks to stimulate innovation and manage associated risks, proposed legislation surrounding AI research and utilization, known as the AI Bill, is anticipated to be enacted in this legislative session, further accelerating AI adoption across various sectors, including manufacturing. However, the study also sheds light on lingering apprehensions among professionals in the field regarding AI's complexity, with many indicating a belief that AI may be too sophisticated or irrelevant to their work.

To bridge this understanding gap, CABDI conducted a survey targeting 300 personnel in the manufacturing sector who actively utilize AI tools to delineate the realities and potential of AI integration.

Key Insights from the Survey

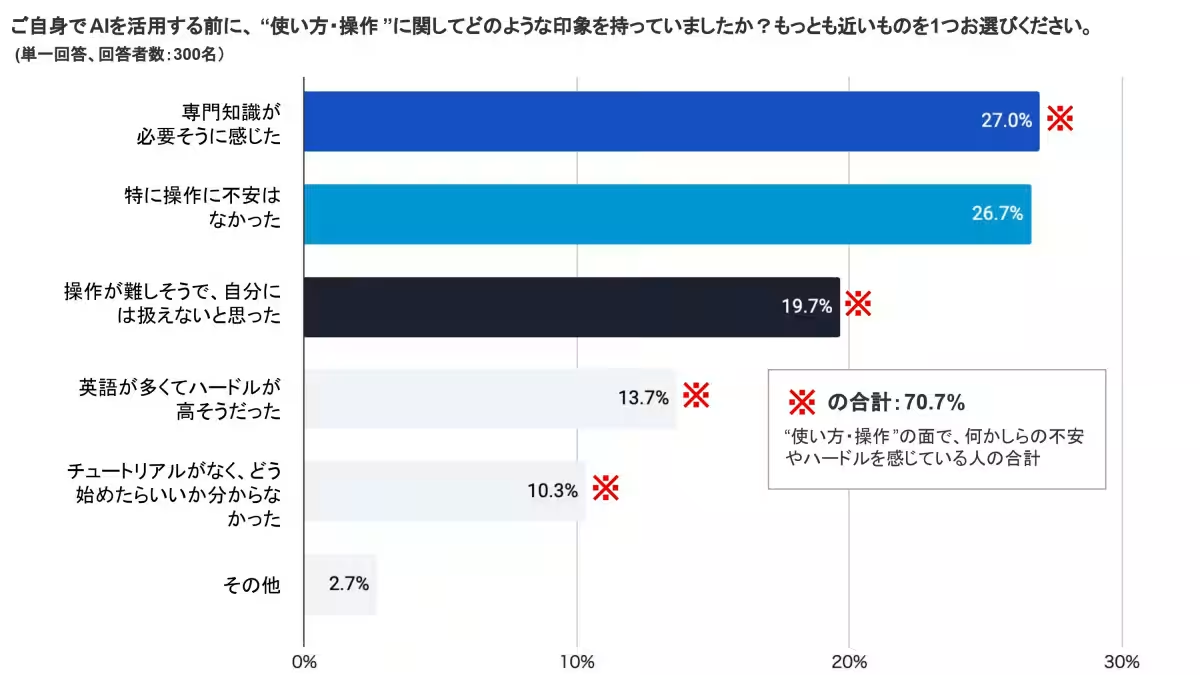

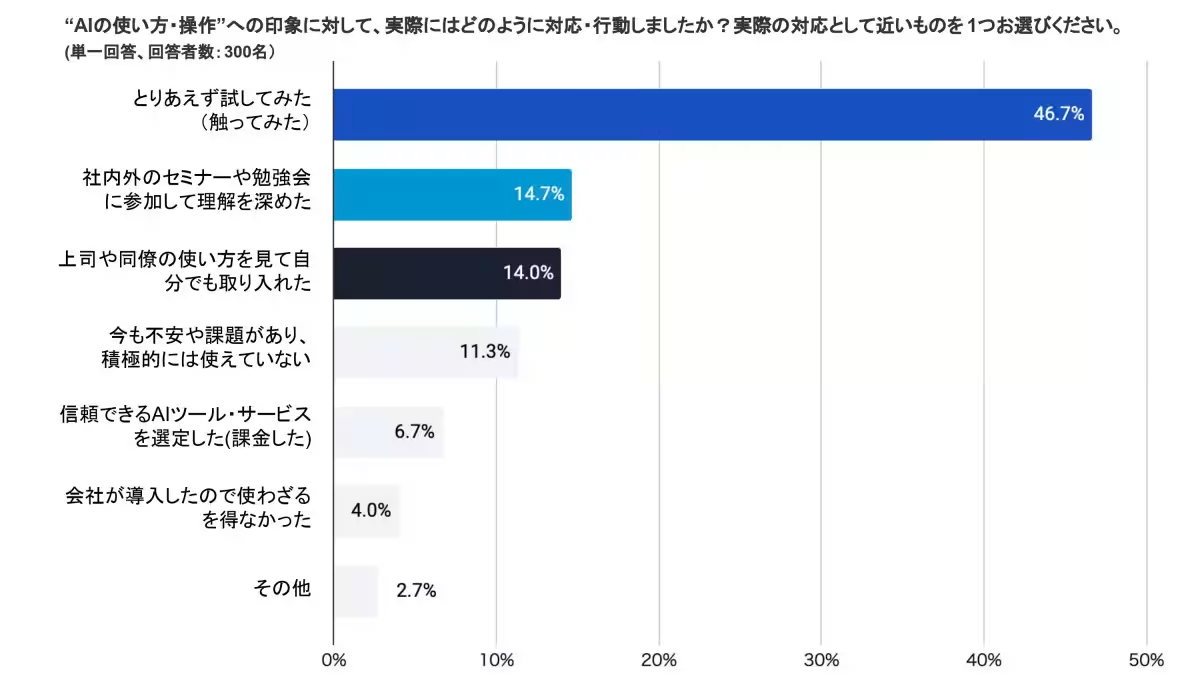

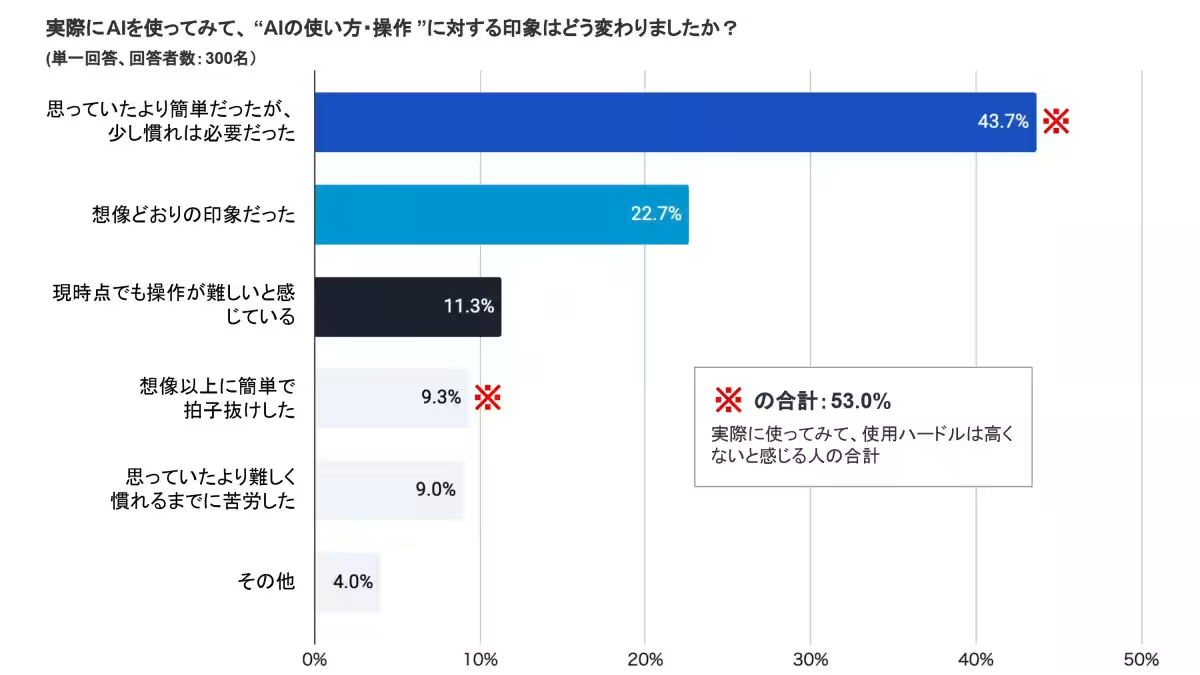

- - Anxiety Before Use: Prior to engaging with AI tools, a striking 70.7% of respondents expressed concerns regarding the operation and usage. The predominant worry was that “expert knowledge seems necessary,” cited by 27% of those surveyed, followed closely by fears of the tools being complicated to operate (19.7%). Interestingly, 46.7% took the initiative to simply try it out, leading to an impressive 53.0% who found the experience easier than anticipated.

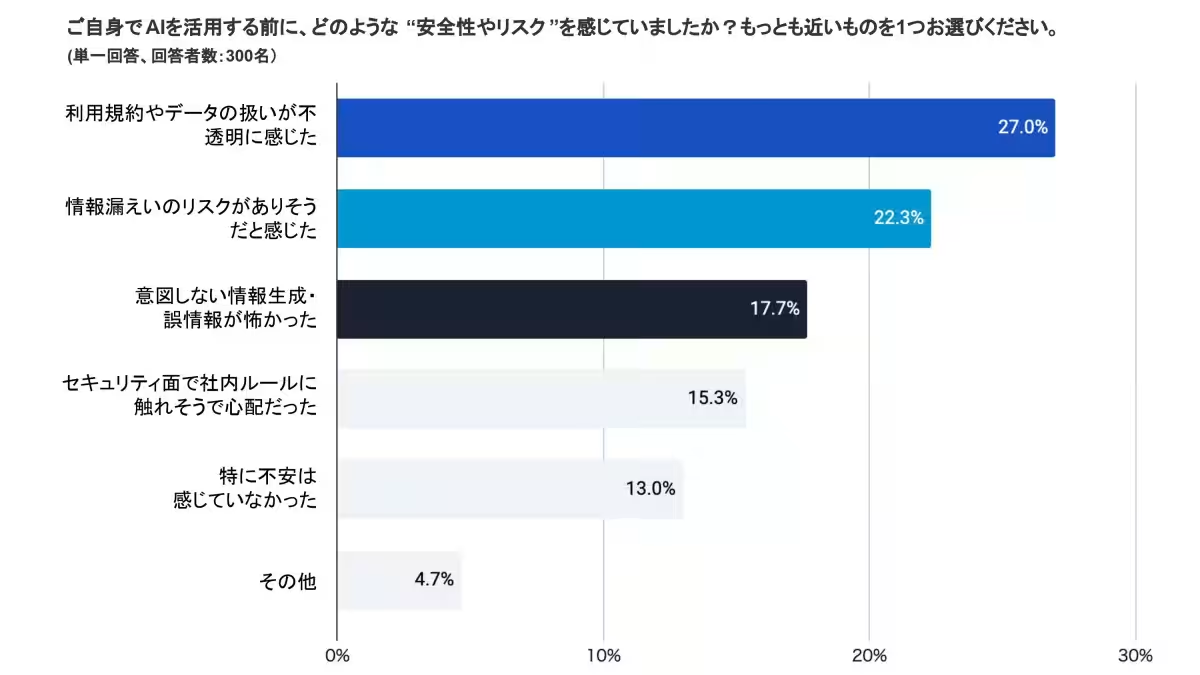

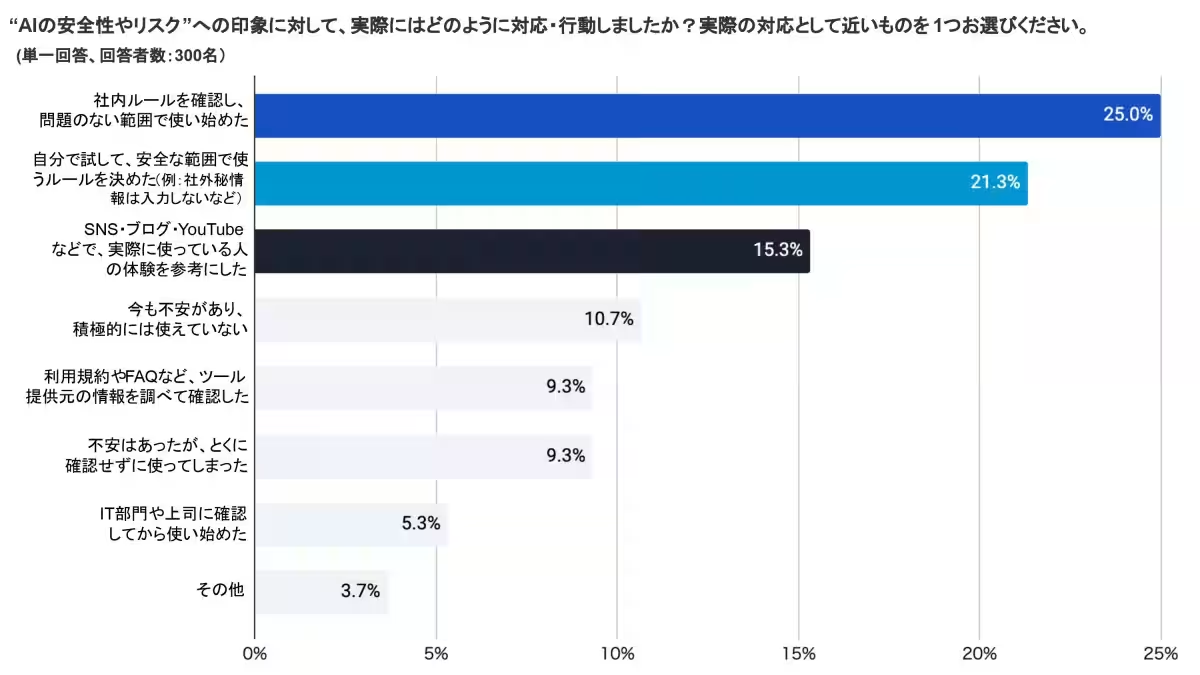

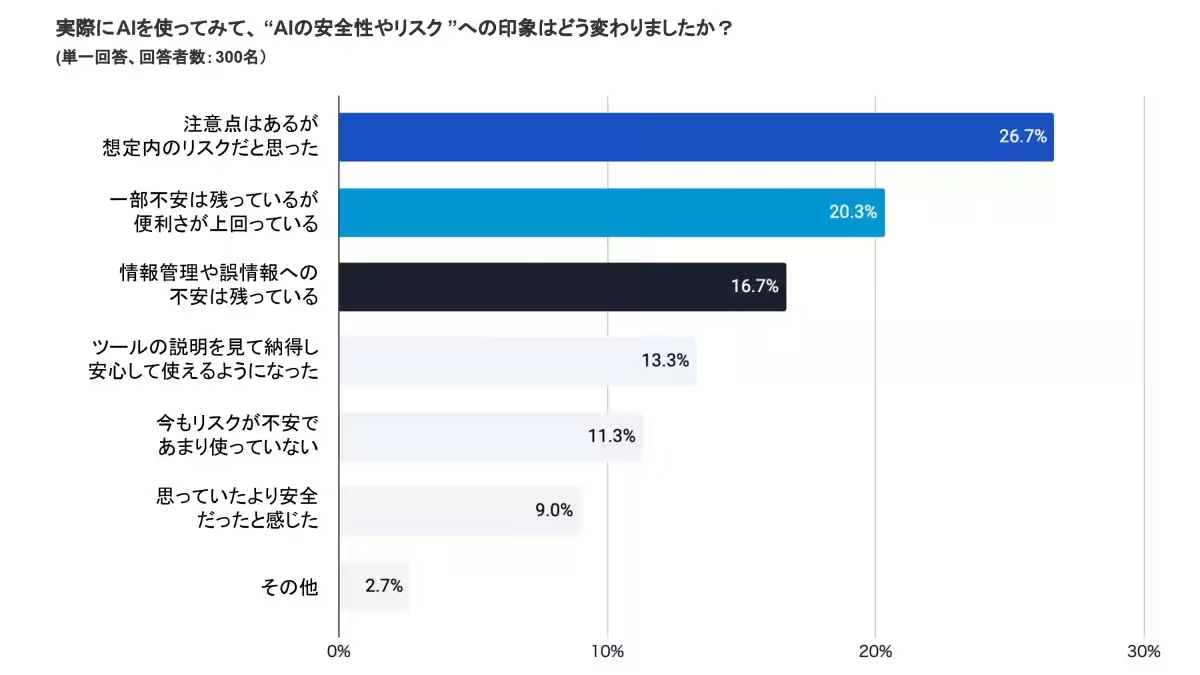

- - Safety and Risk Concerns: A considerable 82.3% of respondents also harbored safety-related apprehensions before starting to use AI tools. Yet, proactive measures were common; around 25% confirmed they had reviewed internal regulations, while 21.3% set personal usage guidelines, demonstrating a cautious yet optimistic approach to AI adoption. Following their experiences, many acknowledged manageable risks, with 26.7% citing “anticipated risks were within expectations,” and 20.3% indicating convenience outweighed concerns.

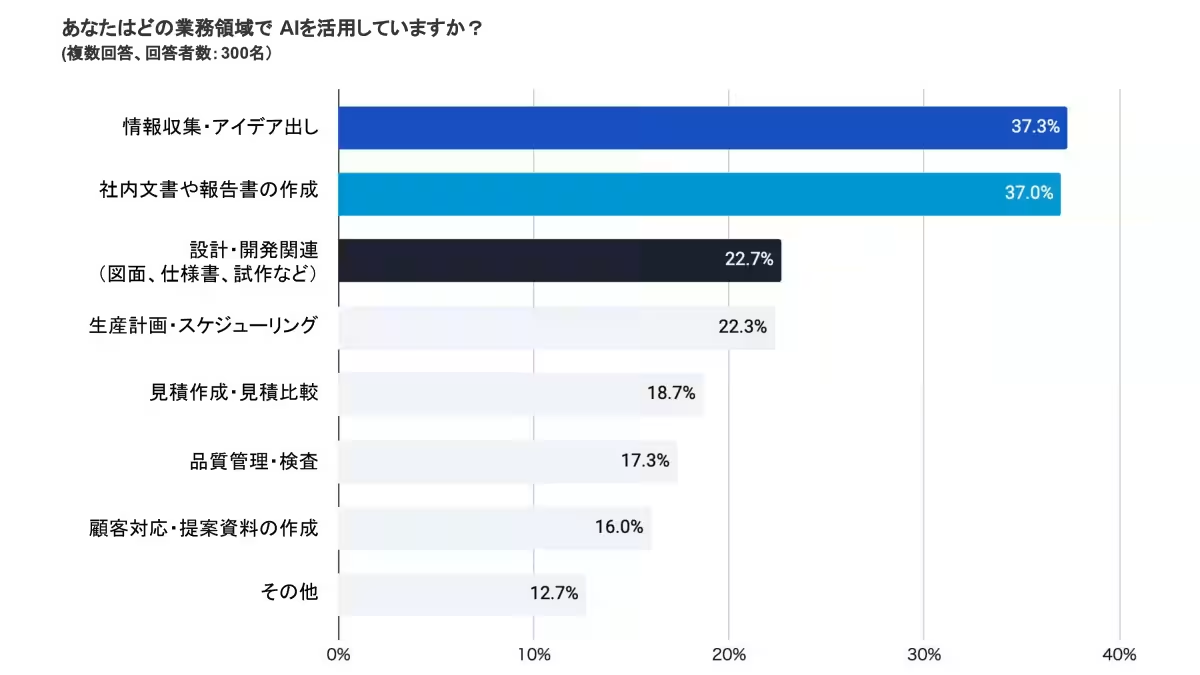

- - Diverse Applications of AI: The spectrum of AI utilization spans various operational domains, with the most common applications being information gathering/idea generation (37.3%) and either internal documentation or report creation (37.0%). Additional areas included design and development (22.7%) and production scheduling (22.3%), showcasing a rich landscape of AI application within specialized manufacturing functions.

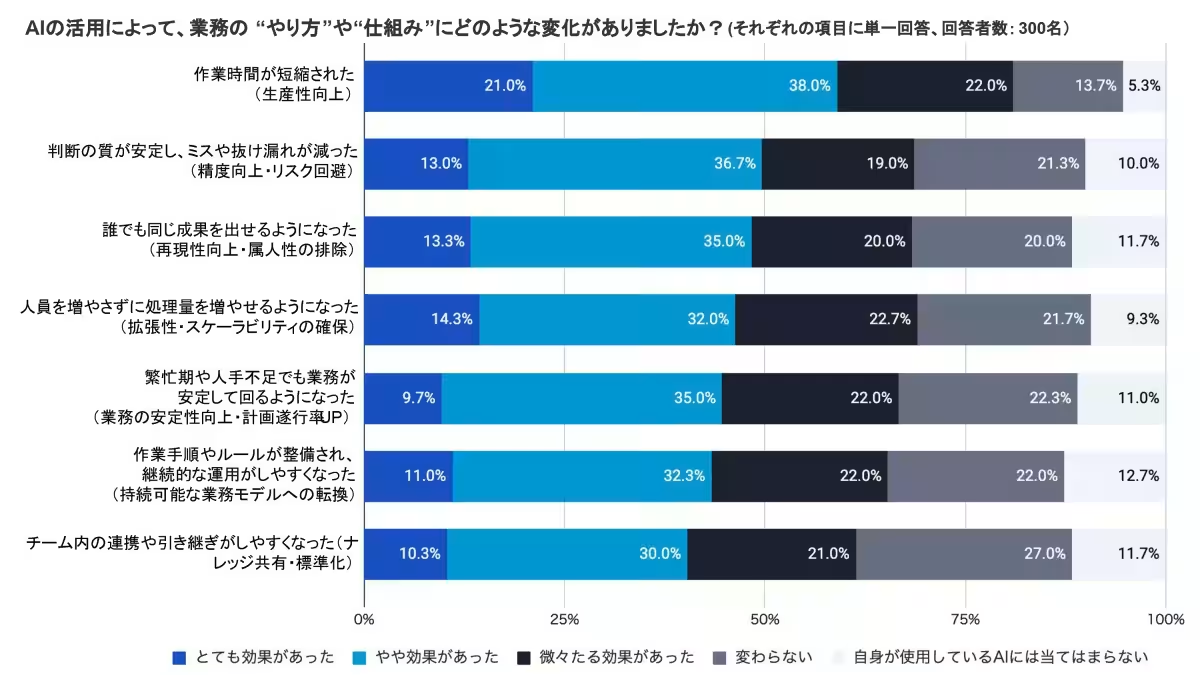

- - Productivity Gains: Notably, the leading impact AI tools had was enhancing productivity at 59.0%, with further notable improvements in accuracy and risk avoidance (49.7%), as well as elimination of knowledge dependency (48.3%).

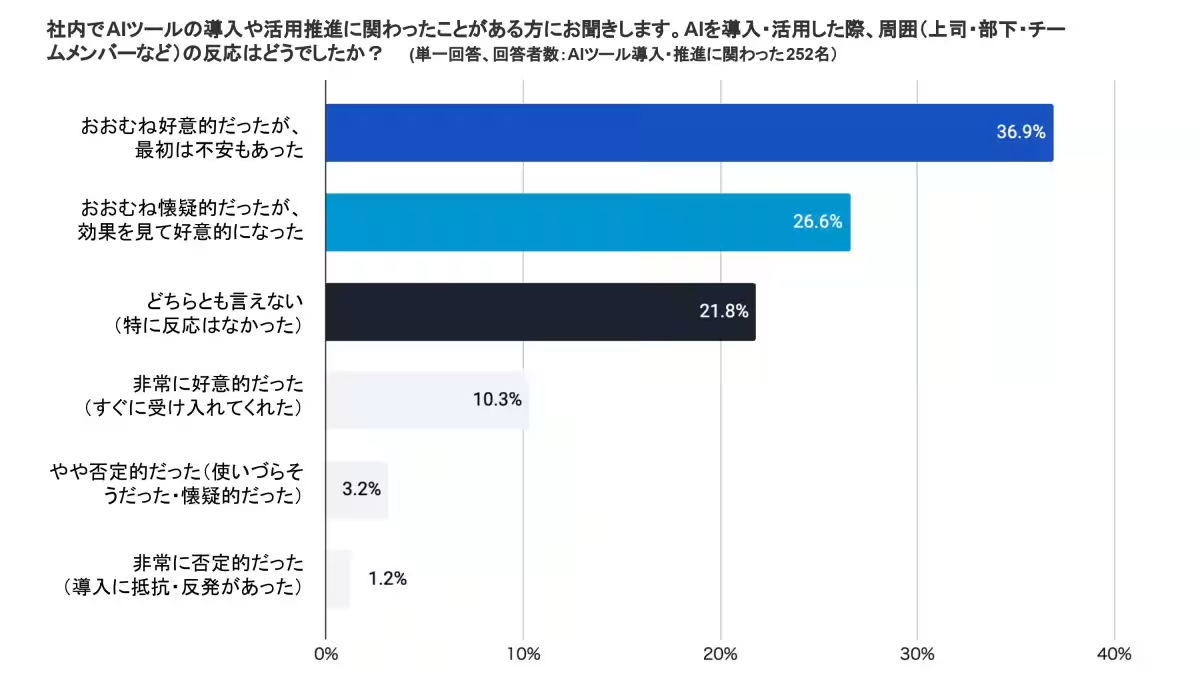

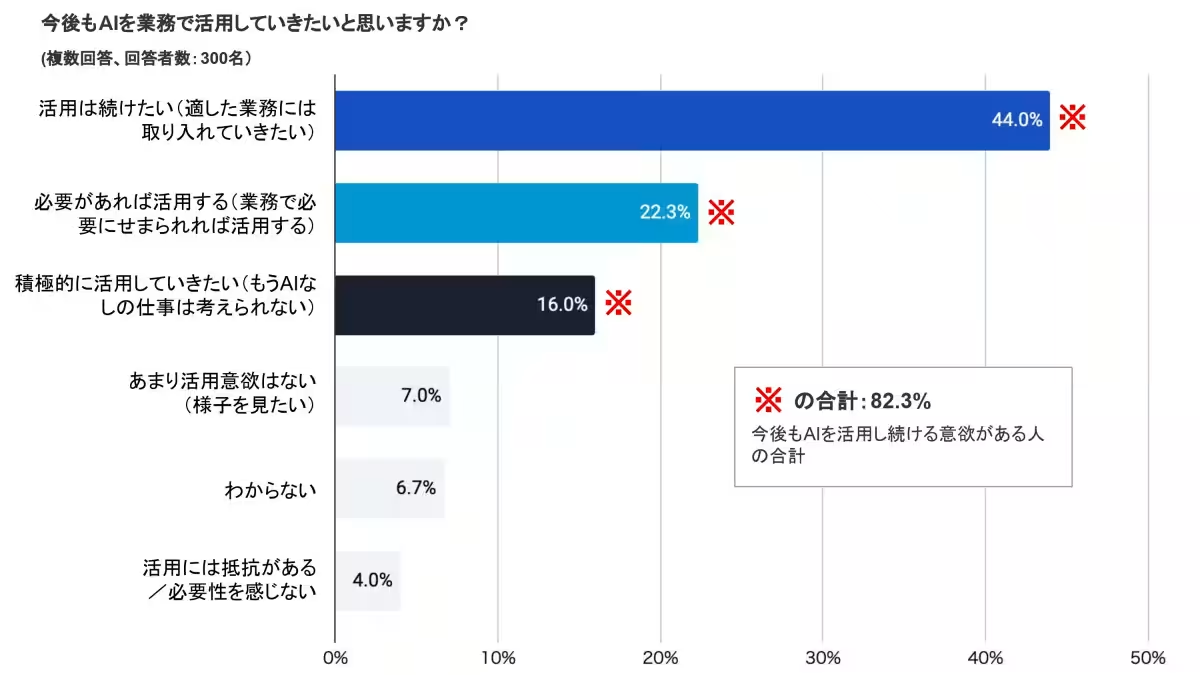

- - Shifting Perceptions: Responses reflect a trend where initial doubts regarding AI usage gradually transformed into a more favorable outlook. About 63.5% of respondents shifted from skepticism to acceptance following their experiences. Looking ahead, 60% expressed intentions to continue engaging with AI, demonstrating a burgeoning acceptance of its role in their workflows.

Real-World Implications and Anecdotes

Participants shared valuable feedback illustrating real-life applications of AI.

- - Streamlined Production Planning: Many noted reductions in labor intensity and customized workflows due to automated scheduling processes, leading to a significant decrease in procedural errors and faster verification lengths for past work.

- - Global Communications: AI tools facilitated the creation of standardized documentation necessary for global operations, such as translating materials, evidencing AI's role in coherence across borders.

- - Creative Support: Professionals reported utilizing AI for creative brainstorming, receiving assistance with data calculations and comparative estimates, signifying AI's value in promoting innovation within manufacturing contexts.

Embracing AI: A Look Ahead

Insights suggest a near-universal drive for continuous AI adoption among respondents, with approximately 80% indicating a desire to maintain their AI engagements in future endeavors. This reflects a significant cultural shift towards embracing technology as a fundamental component of operational effectiveness.

The findings reveal that while initial trepidations surrounding AI were prevalent, many practitioners found substantial operational benefits that counterbalanced their fears. To maximize AI potential, it is critical that companies maintain supportive environments, cultivate familiarity with AI, and foster a culture of experimentation.

As industries ascend through the layered complexities of AI integration, it remains paramount not simply to rely on technology for efficiency but to utilize it as a catalyst for substantive organizational transformation, helping to purge inefficiency and carry forward best practices into the future of manufacturing.

In essence, AI stands not as a replacement for human labor but as a valuable ally in unlocking the full potential of manufacturing capabilities, pushing the industry towards a more advanced and effective operational paradigm.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.