Koito Manufacturing and Mitsubishi Fuso Launch Innovative Proof-of-Concept for Optimizing Manufacturing Workflows

Koito Manufacturing Partners with Mitsubishi Fuso on Innovative Project

In a significant step toward modernizing manufacturing, Koito Manufacturing Co., Ltd., based in Shinagawa, Tokyo, has joined forces with Mitsubishi Fuso Truck and Bus Corporation (MFTBC), headquartered in Kawasaki, Kanagawa. They have initiated a proof-of-concept that utilizes LiDAR technology for Digital Transformation (DX), with the goal of optimizing factory workflows. This collaboration seeks to address critical challenges such as labor shortages and rising energy and logistics costs, which have become pressing issues in the manufacturing sector.

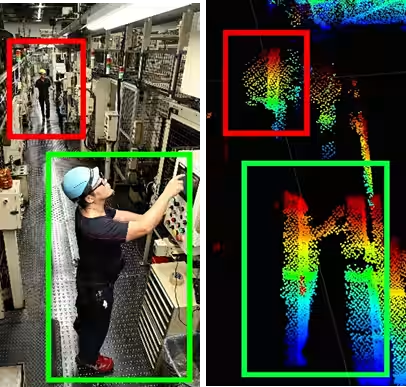

The innovative system, known as "Illumiel®," developed by Koito Manufacturing, leverages advanced 3D sensing capabilities. By employing infrared laser light, Illumiel can measure the distance and positional information of objects with high precision. The data collected is processed into point cloud format, enabling the classification and visualization of surrounding moving entities, such as people and vehicles. This sophisticated data handling allows for a comprehensive understanding of their movements within the manufacturing environment.

MFTBC has recognized the potential of Illumiel to enhance operational efficiency in manufacturing settings. Unlike traditional AI cameras, Illumiel provides detailed tracking of workers and vehicles, which is crucial for analyzing and optimizing workflows. By focusing on data accumulation and analysis, the collaboration aims to eliminate unnecessary operations and reduce the number of vehicles in use. Consequently, this could not only mitigate labor shortages but also contribute to significant cost savings in manufacturing processes.

Currently, three Illumiel units are deployed in the transmission gear processing line at MFTBC's Nakatsu factory in Aikawa, Kanagawa. The installation has already initiated worker movement analysis, with plans to expand testing to the Kawasaki plant in the near future.

Furthermore, Koito Manufacturing aims to utilize Illumiel beyond production optimization. Future applications include enhancing transportation infrastructure to eliminate accidents, realizing fully autonomous driving, and improving operational efficiency in commercial facilities through human flow analysis. These endeavors demonstrate the company's commitment to addressing a variety of challenges across different sectors.

Figure: 3D point cloud data captured by Illumiel showing manufacturing line visualizations.

In conclusion, the partnership between Koito Manufacturing and Mitsubishi Fuso marks a noteworthy advancement in the manufacturing landscape. Through cutting-edge technology like LiDAR, they are poised to redefine production efficiency, paving the way for a smarter and more effective future in manufacturing and beyond.

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.