Enhancing Visibility in Construction Sites with 3D Scanning Technologies

Enhancing Visibility in Construction Sites with 3D Scanning Technologies

Iron Construction Co., based in Chiyoda, Tokyo, has launched an innovative demonstration experiment focusing on 3D scanning technologies, collaborating with Koyo Machinery Industry Co., headquartered in Osaka and i-Robotics Co. in Tokyo. This initiative is aimed at improving construction site visibility and optimizing workflow efficiency.

Overview and Purpose of the Experiment

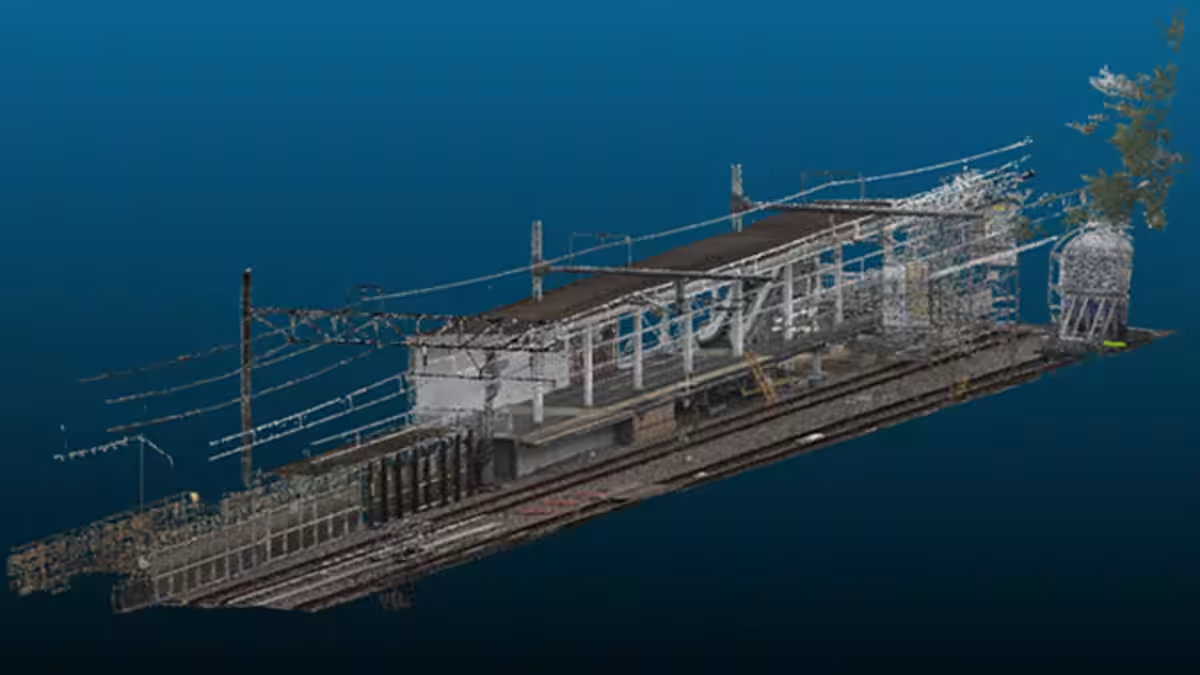

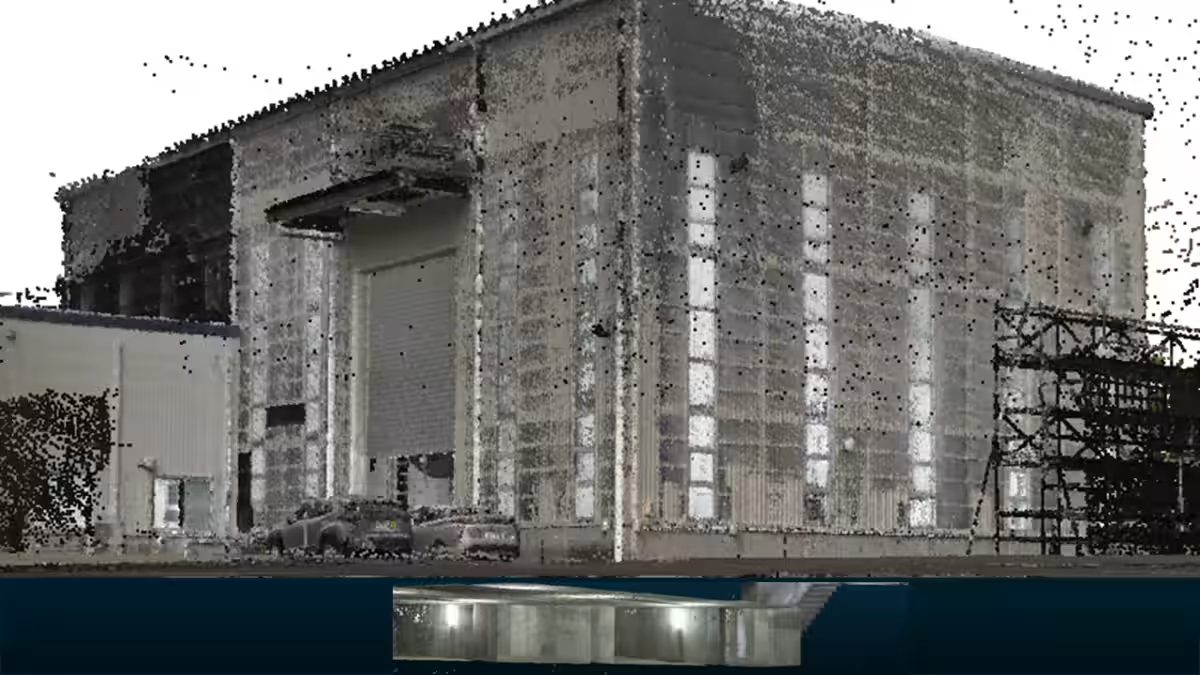

The demonstration experiment is being carried out in the Construction Technology Integration Center, utilizing low-cost and portable technology called the “3D handheld scanner.” The intention is to gather three-dimensional point cloud data which will help in validating machine performance and exploring effective uses for the acquired data.

The primary aim is to identify methods for employing 3D scanning technologies in construction management efficiently, regardless of project scale and type, while enhancing cost-performance.

Background

In recent years, the construction sector has seen a significant shift towards utilizing three-dimensional data that helps streamline various operational processes— from designing structures to management and maintenance. Furthermore, this approach addresses pressing societal challenges such as labor shortages and work style reforms.

Historically, Iron Construction has used 3D data acquisition methods like point cloud surveying and 360-degree imaging; however, due to a shortage of skilled technicians and high costs, the application was limited to large-scale projects. The current experiment aims to overcome these limitations by combining various technologies including the 3D handheld scanner, quadruped robots, and drones equipped with 360-degree cameras to facilitate 3D data capturing adaptable for small to medium-scale projects.

Experimental Results

Initial findings from the demonstration indicate several key advantages of the “3D handheld scanner”:

- - Cost-Effective for Smaller Projects: It can be operated efficiently within limited budgets for medium and small-scale sites.

- - High Precision: It allows for precise point cloud generation in both indoor and outdoor facilities.

- - Reliable Data Collection: Data can be consistently and accurately gathered at a manageable walking speed with the right technique.

- - Enhanced Process Improvement: When the collected data is integrated into project planning and quality control processes, it can lead to significant improvements across the entire operational workflow on-site.

These results will be utilized in further enhancing the operational procedures in alignment with the ongoing digital transformation initiatives across various departments within the company.

Subsequently, Iron Construction plans to continue collaborations with KYC and i-Robotics to further explore and adapt 3D scanning technologies for differing operational models.

Future Prospects

Moving forward, Iron Construction is committed to embracing innovative technologies rather than adhering to specific traditional methods. The company aims to continuously adapt its strategies in response to societal challenges such as labor shortages and workplace reform. Moreover, strengthening collaborative efforts with firms possessing unique construction and digital expertise will be paramount in promoting process automation and sophistication in construction projects.

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.