Innovations in Construction: Autonomous Cable Crane Guided by Local 5G at the Shin Maruyama Dam

Introduction

The construction of Shin Maruyama Dam in Gifu Prefecture is paving the way for revolutionary advancements in construction technology. Obayashi Corporation has made significant strides toward establishing an 'Autonomous Concrete Placement System' supporting the project commissioned by the Ministry of Land, Infrastructure, Transport and Tourism. One of the foremost innovations has been the successful autonomous operation of cable cranes, a crucial aspect of concrete transportation, achieved in February 2025.

Autonomous Cable Crane Operation

The cable crane system signifies a key technological leap, utilizing a wire rope stretched between two points as a track for trolleys to move swiftly. Unlike traditional cranes that often rely on manual operation, the new autonomous capability allows for precision in controlling the swaying of concrete buckets during lifting and placement. Previously, controlling this swaying required real-time communication between the crane operator and a signalman at the concrete release point. However, as experienced construction workers age and new labor shortages loom, automation becomes crucial to maintaining work quality and enhancing safety protocols.

Utilizing Local 5G Technology

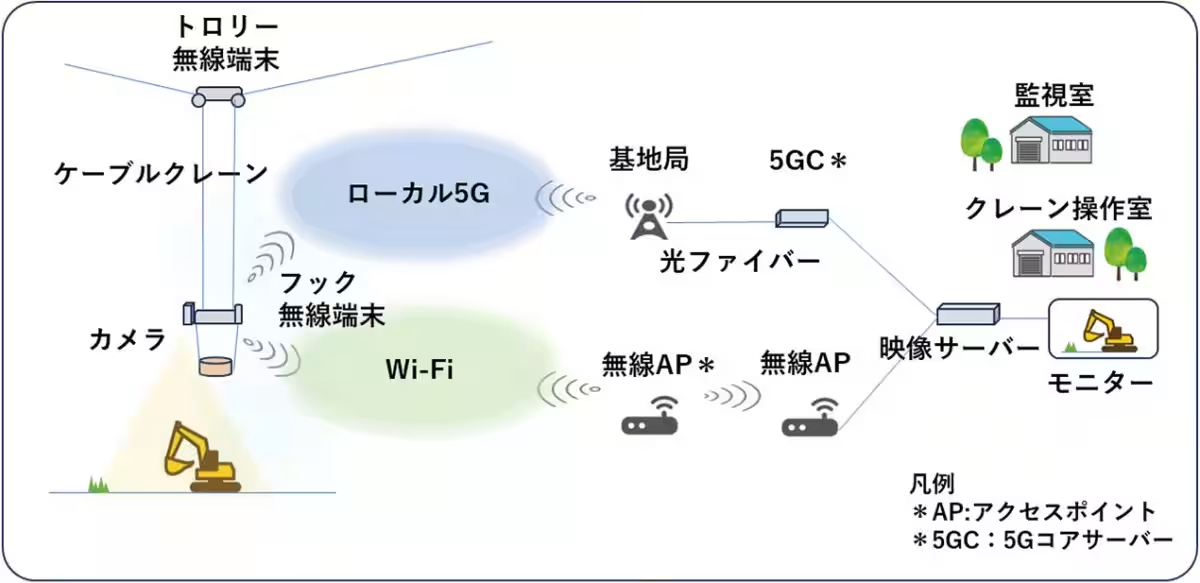

To support this innovation, Obayashi collaborated with KDDI Engineering, leveraging Local 5G—a wireless communication standard that offers remarkable speed and capacity. The simplicity of deploying Local 5G allows for robust communication networks tailored to specific construction sites, free from interference. In December 2023, a trial using ten automated construction machines showcased how Local 5G can handle the high demands of real-time remote driving and operation, even across dynamic construction environments.

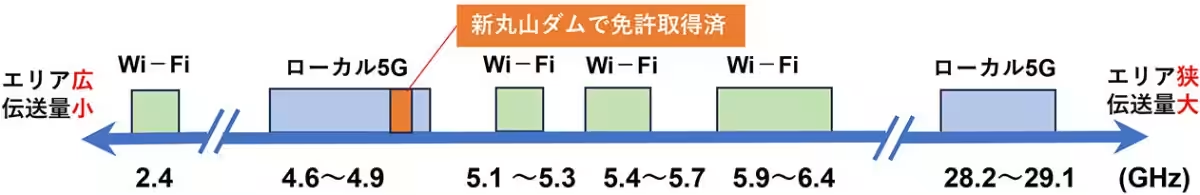

The Advantages of Local 5G

Local 5G operates on frequency bands of 4.5GHz and 28GHz, enabling non-telecom companies to establish secure communication networks. This feature is especially beneficial for remote operation of construction machinery, where high bandwidth is essential to manage multiple devices simultaneously. Unlike other communication methods such as Wi-Fi, Local 5G provides a stable connection that accommodates the fast-paced needs of construction, significantly enhancing productivity while minimizing risks associated with on-site operations.

Video Communication and Monitoring

In the evolving landscape of construction, real-time video transmission becomes invaluable. As part of this initiative, high-resolution cameras are installed on the crane hook, allowing operators to monitor activities closely and ensure safety through instant feedback and adjustments. This advancement not only safeguards the site but also sets a new standard for the operational reliability expected in modern construction projects.

Future Plans and Development

Looking ahead, the implementation of sophisticated AI systems will enhance the operation control of these autonomous cranes. By analyzing the high-quality video feed, the AI can make real-time adjustments to optimize concrete pouring and overall site management. Furthermore, this technology will ease the burdens of labor shortages by ensuring that quality and safety are maintained, even in the absence of skilled professionals. Obayashi Corporation and KDDI Engineering remain dedicated to advancing these initiatives, continuing to explore novel applications of Local 5G in construction to drive digital transformation in the industry.

Conclusion

The Shin Maruyama Dam project exemplifies how innovation, through the integration of Local 5G in autonomous construction equipment, is shaping the future of building infrastructure. By fostering collaboration between tech giants and construction firms, the journey toward a smarter, more efficient construction landscape is well underway, promising safer and more effective work environments for generations to come.

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.