NTT Docomo Solutions and Okumura Corporation Unveil AI-Driven Concrete Ordering Model

Introduction

On September 25, 2025, NTT Docomo Solutions, headquartered in Minato-ku, Tokyo, and Okumura Corporation, based in Abeno-ku, Osaka, announced their groundbreaking AI model designed to automate the calculation of concrete ordering quantities for construction projects. The core of this innovation, based on image recognition AI, has been verified with an impressive accuracy of over 97.5% in identifying unpoured concrete areas under specific conditions.

The Challenge in Concrete Ordering

Traditionally, determining the quantity of concrete needed for construction involves human measurements of unpoured areas, which not only takes time but is also prone to inaccuracies due to human error, leading to discrepancies in ordering amounts. Such discrepancies can significantly impact project timelines and budgets. Additionally, since April 2024, the construction industry in Japan has faced regulations limiting overtime work, making productivity improvements essential. The surplus concrete and returned concrete from pour operations have also escalated costs and environmental impacts, exacerbating existing issues within the industry.

Technological Collaboration

NTT Docomo Solutions has a history of supporting DX (Digital Transformation) in construction by offering image recognition-based services for inspecting the appearances of rebar gas pressure weld joints. By combining NTT Docomo's technological expertise with Okumura's invaluable knowledge in concrete pouring, the two companies successfully developed this AI model. The model’s standout feature is its ability to assess unpoured concrete areas in real-time with remarkable precision, eliminating the need for manual measurements.

Efficiency and Cost Reduction

This innovative approach is predicted to minimize labor hours while enhancing productivity on construction sites. Additionally, by utilizing the AI's assessment results to automatically calculate the necessary concrete quantities, companies can expect to achieve accurate ordering without excess or shortages. This will also help in minimizing the generation of surplus and returned concrete, thereby reducing material costs and waste.

Technical Validation

The recent validation of the technology confirmed the AI’s capability to determine unpoured concrete areas with high precision through the following steps:

- - Timing: The technical assessment was conducted between December 2024 and May 2025.

- - Objective: To evaluate the accuracy of the independently constructed image recognition AI in identifying unpoured concrete areas.

- - Scope: The focus was on improving productivity in concrete pouring operations and minimizing costs associated with surplus and returned concrete.

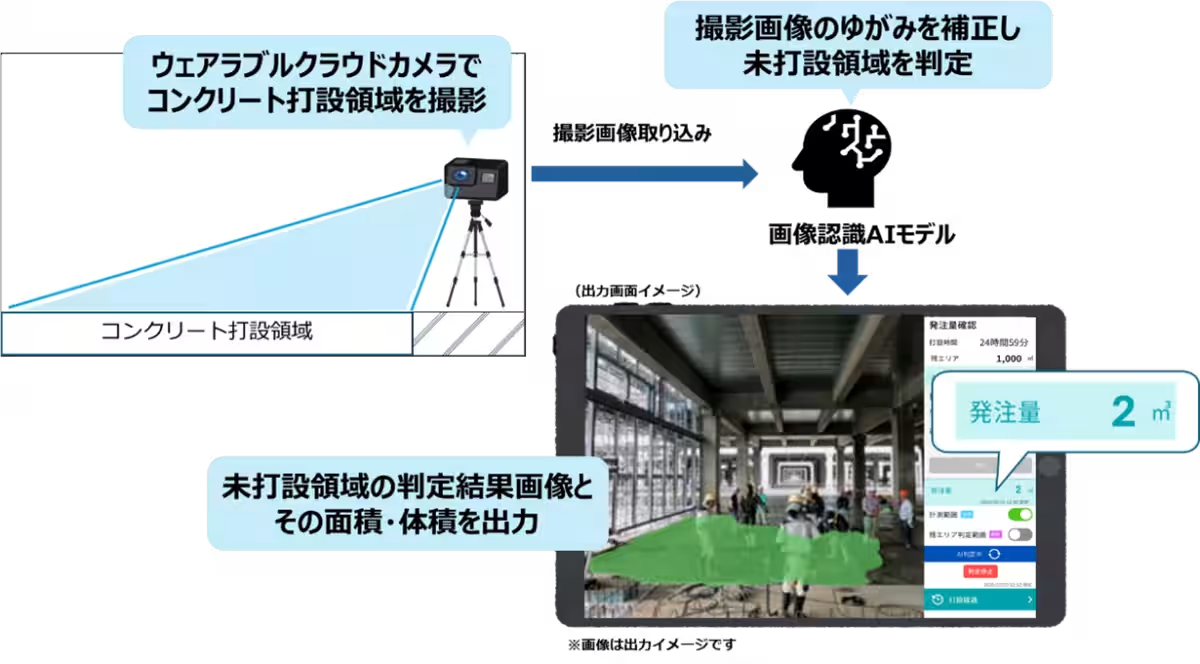

- - Validation Procedure: Images taken at various construction sites, such as warehouses and apartment buildings, were regularly analyzed by cameras installed at the pour locations, allowing for automatic assessments of unpoured areas within a pre-set range.

Key Model Components

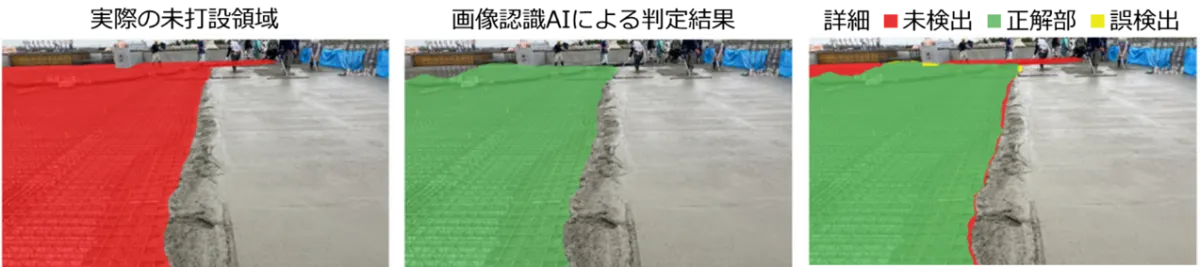

- - Image Recognition AI: Developed by NTT Docomo Solutions, this AI uses semantic segmentation to learn from images captured at multiple concrete pour sites to identify unpoured areas.

- - Image Distortion Correction: The model incorporates techniques to rectify distortions from close-range photographs, enabling precise assessment.

Validation Results

1. The AI model accurately recognized unpoured concrete areas with an accuracy rate exceeding 97.5% when evaluating a designated area of 20m x 10m and 0.2m thick.

2. The judgment outcomes provided by the image recognition AI were deemed feasible for practical implementation in automatically calculating concrete order quantities.

3. The model maintained its accuracy even when equipment or personnel were present in the images, confirming its robustness.

Roles of Each Company

- - Assessment Flow Design: NTT Docomo Solutions and Okumura Corporation.

- - Provision of Video Data: Okumura Corporation.

- - Model Construction and Precision Verification: NTT Docomo Solutions.

- - Perspective Projection Conversion and Distortion Correction Logic: NTT Docomo Solutions.

- - Problem Identification and Strategy Development: NTT Docomo Solutions and Okumura Corporation.

Next Steps

Moving forward, NTT Docomo Solutions and Okumura Corporation plan to initiate practical trials of the automated concrete ordering service in real-world construction settings. These trials will evaluate the accuracy of ordering quantities derived from the AI model and the expected reduction in on-site workload. Feedback from field users will be gathered to assess the model's effectiveness while ensuring that the service aligns with real-world requirements.

The service leveraging this AI model is set to be available as part of NTT Docomo Solutions' GenCon Colabo® lineup, with a target launch date within the 2025 fiscal year. The two companies remain committed to enhancing DX initiatives in the construction industry, aiming to create new value.

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.