Introducing MOLDINO's Advanced Microstep Drilling Technology for High Hardness Steel

The Future of Deep Hole Drilling: MOLDINO's EMSBHE-ATH

MOLDINO, a prominent player in the cutting tool industry based in Sumida, Tokyo, is set to revolutionize the field of precision drilling with its new product, the Epoch Microstep Borer H Evolution (EMSBHE-ATH). Scheduled for release on May 20, 2025, this innovative drill addresses crucial challenges in machining high hardness steel, particularly for deep hole applications.

Development Background

In recent years, manufacturers have been under pressure to reduce costs in tool production, particularly regarding the processing of heat-treated high hardness steel. The traditional method for achieving intricate shapes and holes has been through a technique known as direct drilling, which proves especially challenging for small-diameter, deep holes. While spark erosion has been a go-to alternative, allowing for high aspect ratio drilling, it comes with its own set of drawbacks, such as deterioration in processing quality due to secondary discharge and the short lifespan of the electrode, necessitating frequent changes and constant supervision by operators.

Recognizing these challenges, MOLDINO embarked on developing a solution that could improve the efficiency of the direct drilling process. The result is the EMSBHE-ATH, which features an innovative chip removal system that defies conventional drill design. Early adopters of previous models have reported notable improvements in machining quality and reduced reliance on human operators.

Overcoming Current Limitations

Despite the positive feedback, users have expressed a need for greater stability when processing 60HRC class hardened steels and the capability to accommodate various pin hole sizes in mold manufacturing. In response, the new EMSBHE-ATH has been designed and refined to tackle these specific demands.

Key Features and Benefits

- - Microstep Design for Precision: Tailored specifically for deep hole drilling in high hardness steel, ensuring high precision.

- - Unique Chip Removal Mechanism: This feature, combined with advanced flute geometry, allows for drilling small diameter holes with an L/D of 30.

- - Improved Quality: Compared to spark erosion, the EMSBHE-ATH offers enhanced edge accuracy and surface finish while minimizing burr formation.

- - Automation Opportunities: By enabling machining for various mold pin holes, it significantly reduces the need for manual intervention and opens the door for unmanned operation.

- - Optimized Surface Treatment: Enhancements ensure greater stability during the processing of high hardness steel, particularly in the 60HRC category.

- - Expanded Diameter Range: The drill is available in sizes ranging from Φ0.1 to Φ2, with 124 different items, accommodating various downstream processes such as wire erosion and reaming.

Recommended Applications

The EMSBHE-ATH is particularly recommended for high-precision deep hole machining of small diameters in high hardness steel applications like mold pin hole processing.

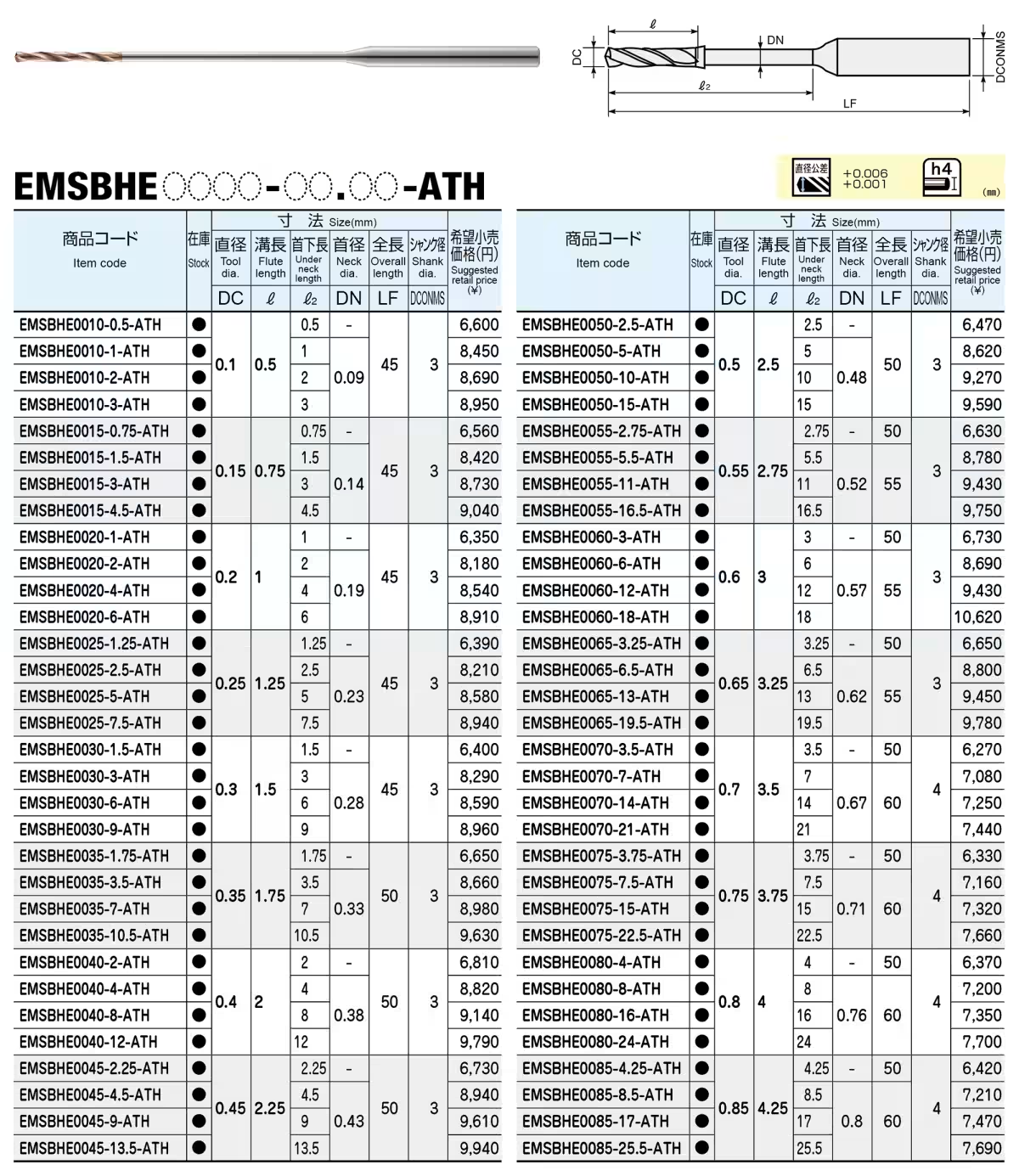

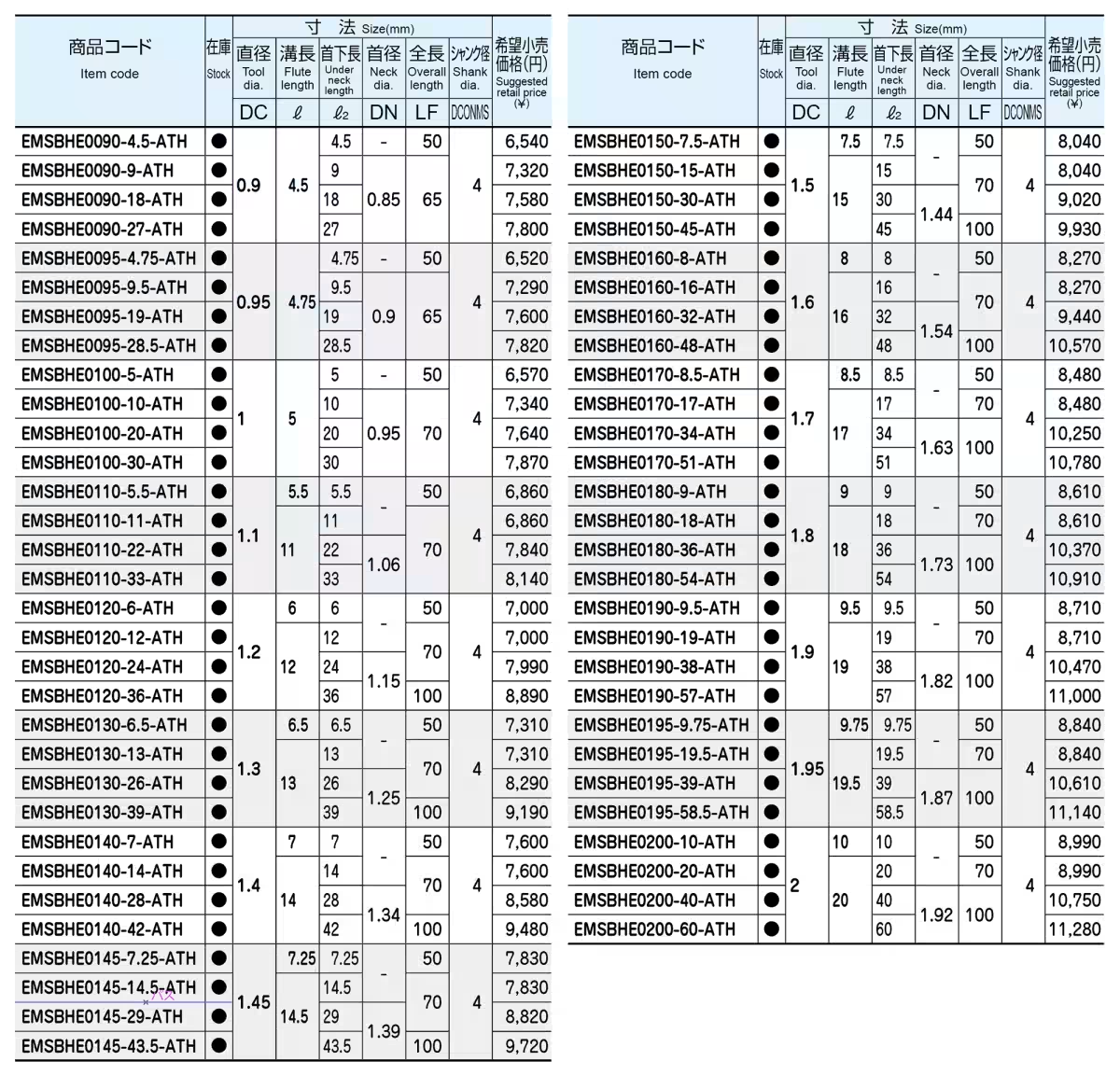

Specifications

- - Tool Diameter: Φ0.1 to Φ2 (124 items available)

- - Price: Ranges from ¥6,270 to ¥11,280 (excluding tax)

Launch Date

Get ready for MOLDINO's groundbreaking tool on May 20, 2025.

For more product information, visit: MOLDINO Products

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.