Ushio Develops Advanced Interference Exposure Equipment for Semiconductor Applications

Ushio's Breakthrough in Semiconductor Exposure Technology

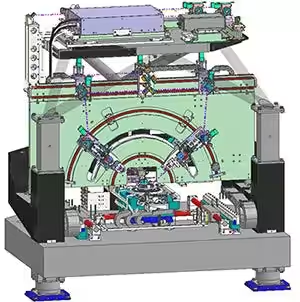

Ushio Electric Co., Ltd., headquartered in Tokyo, has recently announced the successful development of an innovative interference exposure equipment. This new device achieves an impressive pitch accuracy of 0.01nm and is capable of realizing phase-shift structures. The anticipated market launch is set for Spring 2027.

The rapid increase in power demand within data centers, spurred by intensifying competition in artificial intelligence (AI), has highlighted the necessity for advanced optical technology. This has led to a surge in interest for optoelectronic integration. The laser light sources utilized in this integration, particularly the Distributed Feedback Laser Diode (DFB-LD), which incorporates a diffraction grating in the waveguide, have seen skyrocketing demand. However, the production efficiency of Electron Beam (EB) lithography systems, essential for creating these diffraction gratings, has been inadequate, and supply has struggled to keep up. While interference exposure technology holds significant potential to address the low productivity of EB systems, three critical challenges have previously hindered mass production applications:

1. Inconsistent exposure quality

2. Low pitch accuracy

3. Inability to form phase-shift structures

With their latest development, Ushio aims to overcome these three challenges with their new interference exposure equipment.

1. Enhanced Exposure Stability with DPSS Lasers and KrF Resists

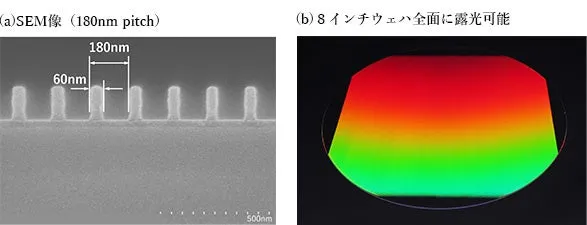

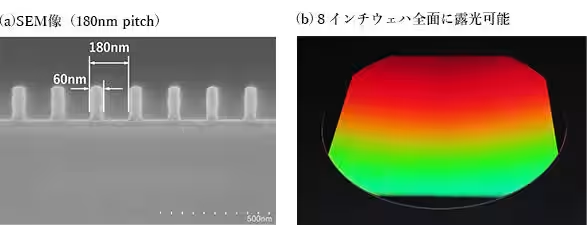

Traditional interference exposure systems commonly employed gas lasers and high-resolution photoresists, leading to lower exposure stability. Ushio's new equipment utilizes a 266nm Diode Pumped Solid State (DPSS) laser combined with chemical-amplified KrF resist, achieving superior exposure stability while maintaining excellent exposure performance (see Figure 1).

2. Achieving 0.01nm Pitch Accuracy with Proprietary Compensation Optics

Ushio's interference exposure device can directly measure the fringe patterns with a pitch accuracy of 0.01nm. It incorporates a compensation optical system that corrects deviations from the target pitch, thereby facilitating the high pitch accuracy required for DFB laser diffraction gratings (see Figure 2).

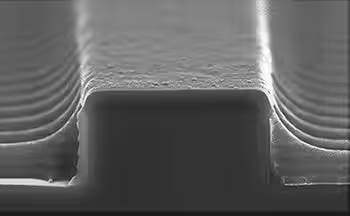

3. Formation of Phase-Shift Structures through Digital Holographic Elements

Phase-shift layers are believed to enhance yield by introducing discontinuous features into the diffraction grating. Ushio's equipment uses a highly controlled digital holographic element that enables the creation of a Corrugation Pitch Modulation (CPM) structure, equating to the functions of traditional phase-shift layers.

As part of the pre-launch phase, Ushio is widely conducting demonstration processes for this equipment, which holds vast potential not only for semiconductor lasers but also for the production of optical parts necessary in Augmented Reality (AR) applications.

Ushio remains committed to driving innovations in the Industrial Process sector through their extensive optical technology expertise. This pioneering technology will also be presented at the upcoming Society Conference of the Institute of Electronics, Information and Communication Engineers (IEICE) scheduled from September 8 to 12 at Okayama University.

Key Specifications of the New Equipment:

- - Compatible Wafer Size: Up to 8 inches

- - Wafer Thickness: Less than 2mm

- - Resolution: Between 150nm and 650nm

- - Shot Size: 13.8×13.8mm, 22×23mm (under development)

- - Alignment Accuracy: 1μm

- - Transport Method: Cassette-to-cassette transport

- - Throughput: Approximately 5 wafers per hour for 6-inch wafers (varies by exposure method)

- - Footprint: 2.5×4m

- - Wafer Materials: Compatible with silicon, glass, compound semiconductors, ceramics, and others depending on adhesion

- - Possible Exposure Patterns: Line and space, dot patterns

- - Duty Control: Possible through exposure amount adjustment (0.3 to 0.55), depending on the resist type

_Ushio Electric Co., Ltd. (Tokyo Stock Exchange Ticker: 6925) was established in 1964. The company manufactures and sells a variety of light sources ranging from ultraviolet to visible and infrared wavelengths, as well as optical and imaging devices. Ushio holds a notable market share across electronics sectors such as semiconductors, flat-panel displays, and has also expanded into life sciences, including medical and environmental fields._

_For more information, visit Ushio's Official Website._

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.