Yamaha Motor Embraces Manufacturing DX with Meviy for AI-Driven Efficiency

Introduction to the New Era at Yamaha Motor

Yamaha Motor Co., Ltd., a global leader in the manufacturing and distribution of motorcycles, marine products, and more, has made a significant leap towards digital transformation in manufacturing by adopting the AI platform, Meviy, from Misumi Group. This integration signifies Yamaha's commitment to optimizing manufacturing processes and improving productivity in an increasingly competitive market.

Background and Challenges

Yamaha Motor operates a vast array of businesses, including land mobility solutions featuring motorcycles and electric-assist bicycles, as well as marine engines and boats. At the heart of their manufacturing philosophy is a concept known as 'theoretical value production activities'. This approach emphasizes maximizing the share of value-creating tasks in order to enhance production efficiency. Yamaha intends to lead the future of manufacturing by focusing on internalizing digital technologies and nurturing on-site scientists.

However, the journey towards this digital transformation is not without its hurdles. As part of their new equipment development process, Yamaha faced two major challenges. The first was the time-consuming necessity to create 2D drawings after designing parts in 3D CAD. This process consumed immense resources without adding value. The second challenge involved training inexperienced staff in 2D drawing techniques, which was essential yet time-intensive.

Implementation of Meviy and its Impact

1. Significant Reduction in Design Time

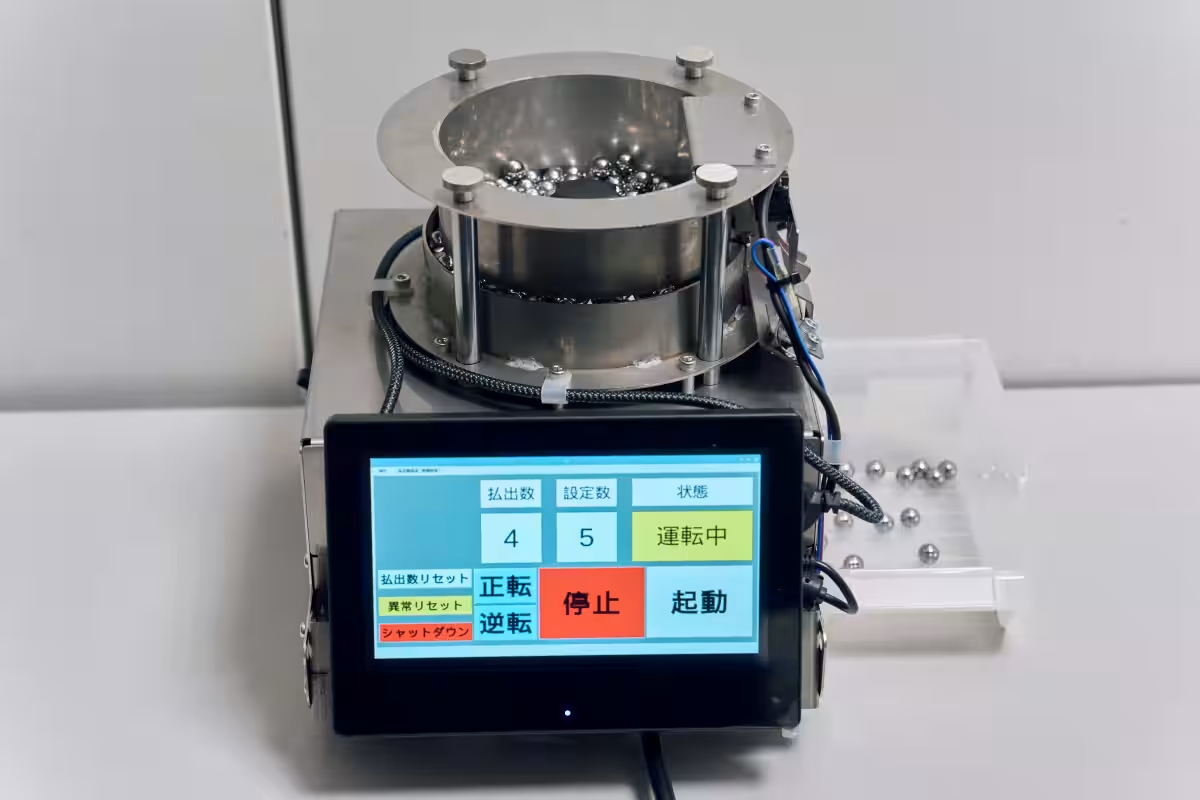

By employing Meviy across various equipment and devices, Yamaha has eliminated the need for 2D drawing creation. This has freed up valuable time to focus on enhancing accuracy and usability. One of the standout projects to emerge from this initiative is the development of an affordable parts counter, which was a collaboration with Yamaha Motor MIRAI, a division focused on promoting employment for persons with disabilities. The goal was to create a design that features clarity and ease of use. Through Meviy, Yamaha was able to dedicate time to trial and error, ultimately delivering devices that met usability and safety standards.

Moreover, the parts counter was manufactured at a cost lower than commercial offerings, thanks to Meviy's AI-powered estimation tool, which allowed for extensive revisions—up to 30 iterations per part—leading to significant cost savings.

2. Contribution to Designer Education

Meviy has also transformed the educational landscape for new designers within Yamaha. Typically, teaching inexperienced workers requires individualized guidance on 2D drawing and material characteristics. However, with Meviy's capability to provide estimates based solely on 3D data, supplemented by a wealth of technical information available online, the learning curve has dramatically shortened, facilitating the swift acquisition of design skills.

Quotes from Yamaha Motor Officials

Yamaha Motor's Automation Technology Development Group has shared insights regarding the implementation. Tetsuya Sasaki, a member of the group, mentioned: "We currently use parts produced via Meviy across the board in new equipment development. Without the time taken by 2D drawings, we can now engage in extensive trial and error. Furthermore, those who have the motivation for on-site improvements but lack the skills are now able to contribute meaningfully thanks to Meviy."

Adding to this, Tetsuya Natsume from the same group noted: "Those who previously struggled to realize their ideas can now turn concepts into reality by simply mastering CAD operation. The rich technical knowledge available on the Meviy site enabled me to complete my first designed equipment in about six months."

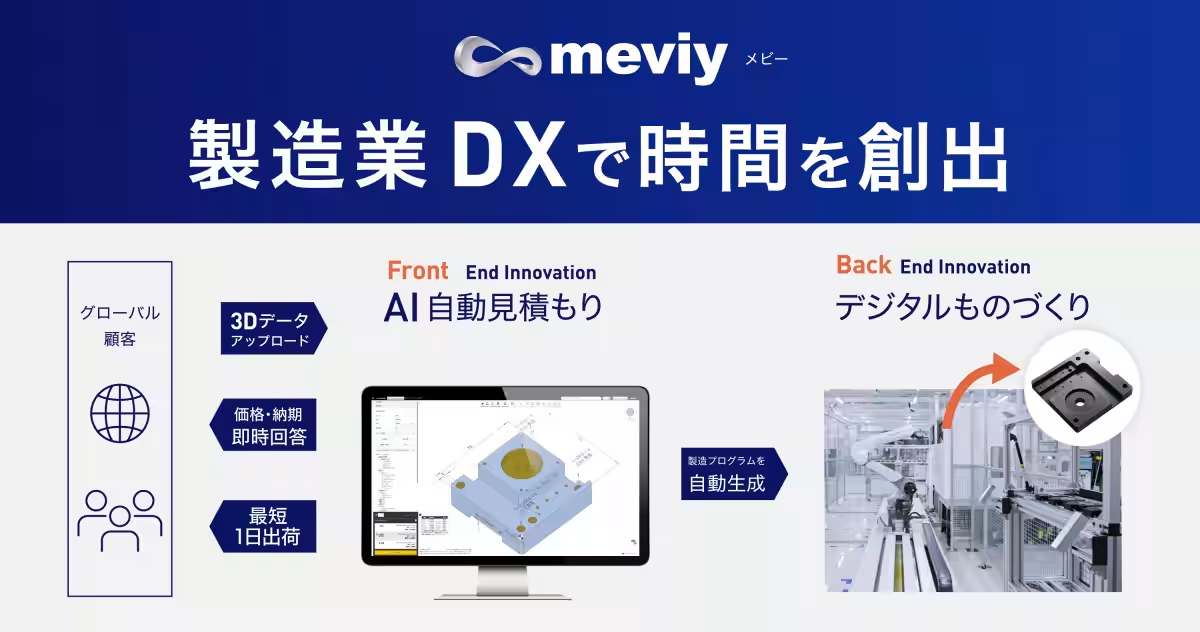

About Meviy

Meviy offers a revolutionary approach to the procurement of machine parts, allowing users to upload 3D data for instant quotes via AI, significantly reducing the time usually required for parts procurement by over 90%. With a strong track record, Meviy has been recognized as the number one platform in Japan for four consecutive years and received the Prime Minister's Award at the 9th Monozukuri Nippon Grand Award, highlighting its role in enhancing productivity in manufacturing.

About Misumi

Misumi operates a unique business model, combining manufacturing functions and the sale of other brands' products. With a client base that includes over 323,000 global companies as of March 2025, Misumi is committed to providing precise and timely delivery of essential machine parts.

As Yamaha Motor continues to integrate Meviy into its operations, the potential for increased efficiency and productivity signifies an exciting future in manufacturing productivity and innovation.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.