Mitsubishi Corporation's Mill-Box Revolutionizes Mill Sheet Management in Construction Industry

Mitsubishi Corporation's Mill-Box: A Game Changer for Mill Sheet Management

In a significant move to modernize the construction industry, Mitsubishi Corporation's Material Solutions Group has introduced Mill-Box, a cloud-based system that digitizes the management of mill sheets, crucial documents certifying the quality of steel materials used in construction projects. Recently adopted by Shimizu Corporation for their Torch Tower project, this innovative solution promises to enhance operational efficiency and significantly reduce workload on site.

The Challenges of Traditional Mill Sheet Management

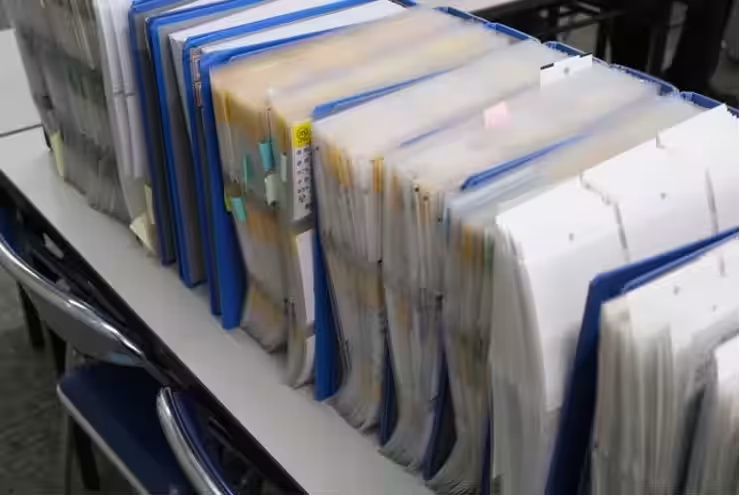

In large-scale construction projects, like the Torch Tower, a substantial number of documents need to certify the quality of the steel materials utilized. Previously, these mill sheets were typically managed on paper, demanding meticulous manual checks for discrepancies in steel diameter weights and alignment with reinforcements provided by processing companies. Such a process not only added burdensome workload but also impacted productivity, requiring dedicated personnel to manage these tasks effectively.

The manual process often resulted in delays, misreporting, and even potential compliance issues—significant challenges that the construction sector has grappled with for years.

Embracing Digital Transformation

Recognizing the pressing need for efficiency, Shimizu Corporation has continuously sought to enhance operational procedures through digital solutions. The adoption of Mill-Box was met with an immediate interest due to its intuitive interface, which enables on-the-ground teams to access its functionalities without extensive training. However, the construction industry's tradition of requiring physical mill sheets during inspections posed a significant barrier.

Mitsubishi Corporation addressed this issue by consulting with designated confirmation inspection bodies, ensuring that electronic data could be utilized under certain oversight conditions. This proactive approach significantly lowered the barriers to Mill-Box's implementation, allowing for a smoother transition to digital operations.

The Positive Outcomes of Mill-Box Implementation

The adoption of Mill-Box has resulted in remarkable improvements, significantly reducing task completion times by approximately 50%. By automating the aggregation of data and tracking discrepancies, the system offers immediate visibility into processing statuses. The elimination of errors from manual data entry further streamlined operations, culminating in the automatic generation of inspection documents.

As one of the Shimizu Corporation's representatives noted, “The ability to consolidate and aggregate data automatically has drastically minimized the time spent on manual corrections and errors.”

Furthermore, the cumbersome task of retrieving necessary mill sheets for inspections has been simplified; inspectors can now access the required information instantly. This advancement means that the inspection processes have become more efficient, allowing for necessary documentation to be presented without delay.

An implication of this efficiency has been the continuous improvement of residents and partners’ workflows, enhancing overall communication and response times regarding quality assurance measures.

Looking Ahead: Future Prospects for Mill-Box

Mill-Box is built on the principle of fostering an ecosystem where various stakeholders, including construction companies, trading firms, manufacturers, and inspection organizations, can collaborate seamlessly. With ongoing feedback and continuous improvements, the platform aims to elevate productivity standards across the steel distribution and construction sectors.

Mitsubishi Corporation remains committed to the development and operational support of Mill-Box, ensuring it aligns with real-world applications and addresses the industry's challenges effectively. The goal is to foster a more interconnected and streamlined approach to mill sheet management, ultimately contributing to enhanced efficiency and quality control in construction projects.

About Mill-Box

Mill-Box is that modern cloud-based solution that significantly restructures how mill sheets are created and managed, allowing for seamless integration with steel tags, quantities, dimensions, searches, and inspections. By alleviating traditional paper-based burdens and enhancing error management through a simplified interface, Mill-Box sets a new standard for operational efficiency in construction.

For more information, visit the Mill-Box website.

Media Inquiries

For media inquiries regarding this advancement in mill sheet management, please contact:

- - Mitsubishi Corporation

Email: [email protected]

Phone: 080-5029-1250

- - Public Relations Team

Explore more details of this and other press releases from Mitsubishi Corporation at PR Times.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.