Revolutionizing Component Storage and Picking with T-AstroX Automation Solutions

T-AstroX: Automating Manufacturing Component Handling

In a significant move to enhance automation in the manufacturing sector, Tsubakimoto Chain Co., based in Osaka, Japan, has secured an order for the cutting-edge three-dimensional material handling system, T-AstroX, from Omori Machinery Co., known for its packaging machinery and systems. The T-AstroX system is slated to go live at Omori's Koshigaya factory by June 2026, heralding a new era in component storage and picking efficiency.

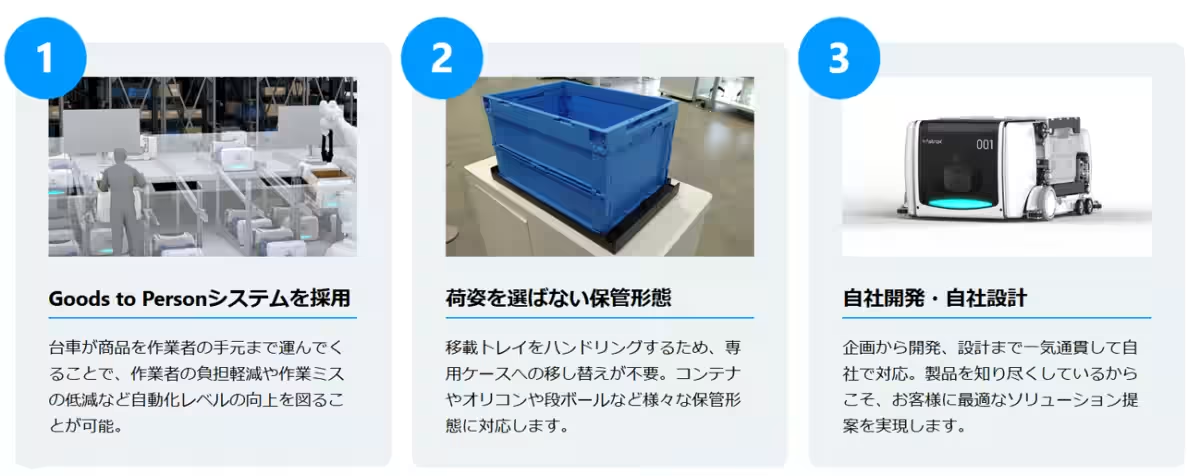

What is T-AstroX?

T-AstroX is designed to automate multiple processes of goods handling, significantly improving efficiency in logistics centers and manufacturing plants. This Goods to Person (GTP) system comprises storage shelves for items, robots for transportation, and workstations for piece-picking and inventory management. By implementing T-AstroX, companies can effectively combat labor shortages and streamline their operations, ensuring tasks are completed with increased speed and accuracy.

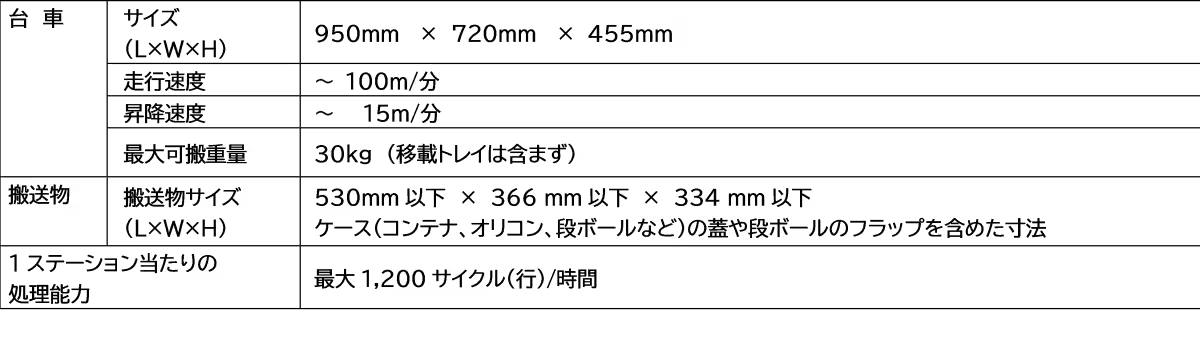

Key Features and Specifications

The T-AstroX system will manage around 40,000 components, covering approximately 2,000 different types, along with about 1,500 work-in-progress items. The system can handle over 1,000 inbound and outbound movements daily, facilitating high-efficiency inventory management tailored to the needs of modern manufacturing.

Customization and Support

One of the standout aspects of T-AstroX is its customization potential. Tsubakimoto has tailored the workstation designs and operations to meet the specific operational needs of Omori Machinery. In addition, they offer a 24/7 on-call service, showcasing their commitment to customer support and maintenance, which is a critical factor in the implementation of advanced manufacturing solutions.

Addressing Industry Challenges

Founded in 1917, Tsubakimoto has continually supported global manufacturing needs from machine parts to transportation systems. As the industry faces pressing challenges such as the 2024 labor shortages and increased demand for automation, T-AstroX emerges as a promising solution to improve productivity while minimizing environmental impact. By efficiently controlling the flow of materials and information, Tsubakimoto aims to significantly contribute to resolving these essential issues in the logistics and manufacturing sectors.

Specifications of T-AstroX

- - Number of Stations: 3 units (for inbound and outbound operations)

- - Effective Openings: Approximately 1,800 openings

- - Number of Transport Robots: 4 units

- - Operational Hours: 8 hours/day

Visit and Learn More

For those interested in a closer look at T-AstroX, Tsubakimoto offers live demonstrations at their material handling exhibition space, M.LABO, located in Hanno City, Saitama Prefecture. Advance reservations are required to experience the future of component handling firsthand.

Contact Information

For inquiries and additional information, please reach out to the Material Handling Division, Sales Department 1 (Tokyo) at TEL: 03-6703-8402.

To learn more about the innovative T-AstroX system, visit the official website: Tsubakimoto T-AstroX.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.