Introducing the New CSH36-6 Crane: Enhancing Safety and Productivity in Tower Construction

Kato Works Unveils the CSH36-6 Crane

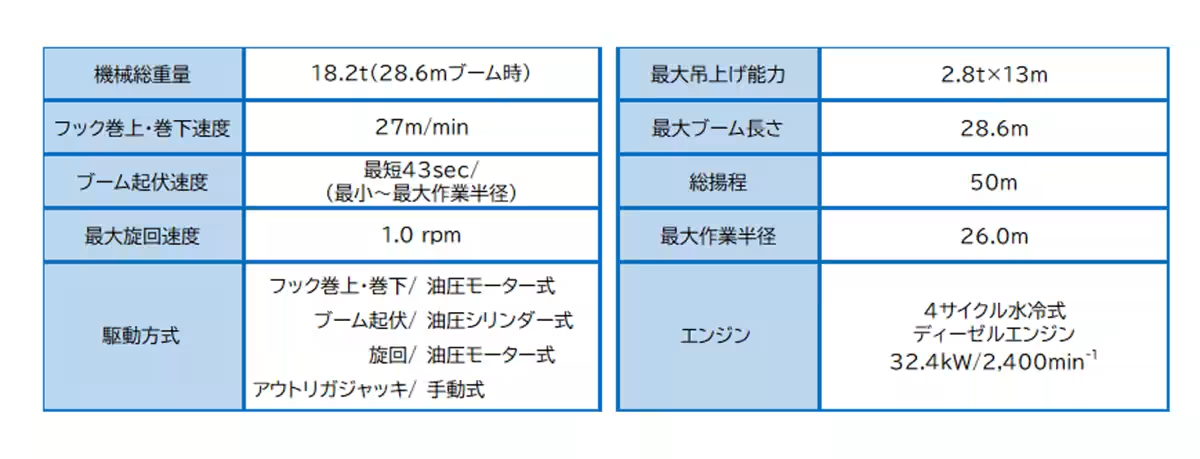

Kato Works, a prominent Japanese manufacturer based in Shinagawa, Tokyo, has recently introduced its latest 2.8-ton assembly stationary jib crane, the CSH36-6, set to launch in June 2025. This innovative crane is designed specifically for tower construction tasks, significantly enhancing work efficiency and safety in the industry.

Background of Development

In recent years, the adoption of renewable energy sources has accelerated, leading to a concentrated demand for power generation facilities in remote locations. As the need for new transmission routes grows, the aging of the national transmission line infrastructure further complicates the scenario. The shift towards a more advanced, bidirectional power transmission grid, propelled by power liberalization and the increasing prevalence of decentralized power sources, is expected to drive the demand for new and replacement tower construction even higher.

Despite this burgeoning need, many construction companies rely on cranes that were introduced during the peak of transmission line construction in the 1990s. Many of these cranes have now reached the end of their operational life, resulting in a significant shortage of functional equipment on construction sites.

Recognizing these challenges, Kato Works set out to develop the CSH36-6 crane. This model aims to facilitate tasks like the removal of excess soil and the transportation of materials during deep foundation work. While inheriting the operational capabilities of previous models, the CSH36-6 features a comprehensive overhaul of its outrigger, lower frame, power unit, and operator seat unit. These improvements promise enhanced efficiency in assembly and disassembly, better workability, and increased safety—particularly in difficult terrains like mountainous and sloped areas.

Key Features

1. Educational Certification Required:

The operator can handle the crane with specific education related to cranes under five tons, eliminating the need for a specialized license or skill courses.

2. Sturdy Construction:

The crane complies with construction structural standards, ensuring robust performance and reliability.

3. Enhanced Performance:

a. New Remote Control:

The CSH36-6 comes equipped with a lightweight, compact remote control that reduces the operator's burden.

b. Two-Speed Winch:

The winch is now available as a two-speed option, allowing faster operations for lifting and lowering materials.

c. Larger Drum Diameter:

The winch drum's diameter is increased to approximately 1.5 times that of previous models, improving stability and enabling quicker operational speeds.

4. Hydraulic Boom Elevation:

The boom's elevation mechanism utilizes hydraulic cylinders, providing smooth operation without concerns about wire rope overlaps. A counterbalance valve activates at the neutral position of the control lever, maintaining the boom's operational angle.

5. Unlimited 360° Rotation:

The crane's ability to rotate indefinitely expands the operational range, significantly enhancing the efficiency of crane operations.

6. Improved Assembly and Maintenance:

a. Pin Connection Technique:

By adopting pin methods for connecting various components, assembly processes have become simpler.

b. Streamlined Bearing Installation:

A reevaluation of the turning bearing's installation structure has simplified previous auxiliary works.

c. Fuel Tank Relocation Changes:

By relocating the fuel tank and modifying the power unit's structure, assembly time and strain have been notably reduced.

d. Simplified Operator Unit Design:

Improvements to the operator's unit have led to a reduction in assembly and disassembly tasks.

7. Slope-Adaptive Lower Frame and Outrigger Beam:

The new model features integrated adjustment capabilities for slope angles, enhancing usability and transportability.

Enhanced Transportability

Thanks to the optimization of disassembly units and components, the crane is now significantly lighter, improving transport options such as cable cars or helicopters.

Safety Features

The CSH36-6 includes two newly developed operational range limiting devices (patents pending) that restrict both horizontal and vertical movement, thereby increasing safety during crane operations. Moreover, a three-point safety gear on the boom includes a step, stanchion, and safety rope guide to enhance safety during assembly tasks. An additional tilt alarm system warns operators of any machine tilt, ensuring constant safety awareness.

Product Overview

- - Model: CSH36-6

- - Release Date: June 2025

- - Retail Price: Starting at ¥40,000,000 (excluding tax; prices may vary based on equipment)

- - Annual Sales Target: 20 units

Company Information

Kato Works, established in 1935, has a long-standing history of manufacturing construction cranes, hydraulic excavators, and other relevant products. The company's current headquarters is in Shinagawa, Tokyo, and it aims to continue contributing to infrastructure development for a sustainable society through innovative products.

For press inquiries, please reach out to:

- - Kato Works Corporate Communication Department

- - Phone: 03-3458-1144

- - Email: [email protected]

For product inquiries, visit our official website.

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.