ZREK Selected for Kawasaki City's Small Business DX Model Project

ZREK Selected for Kawasaki's Digital Transformation Project

The AI startup ZREK (pronounced: Zurek), headquartered in Shibuya, Tokyo, and managed by CEO Yuki Imamura, has recently been granted approval for its project under the Kawasaki City Small Business DX Model Development Support initiative for the 2025 fiscal year. This program is aimed at supporting local small- to medium-sized enterprises (SMEs) in leveraging digital technology for innovative business models and operational reforms.

Overview of the Kawasaki City Small Business DX Model

The Kawasaki City Small Business DX Model Development Support initiative fosters projects where SMEs can explore and implement digital solutions to overcome challenges faced in their respective industries. Selected businesses are eligible to receive financial support of up to 3 million yen as well as mentoring from industry experts, enabling them to advance their pilot developments.

Details of the Selected Project

ZREK's designated initiative is focused on automating CNC lathe operations specifically within the metal processing sector. By utilizing specialized AI and integrating robotic arms (also known as collaborative robots), this project aims to remove traditional human labor requirements involved in machining processes. The goals are to enhance productivity and address the labor shortage in manufacturing.

Unique Features of the Initiative

1. Overcoming Metal Processing Challenges with Automation

Traditional operations involving collaborative robots in CNC lathe tasks face significant hurdles, including time-consuming work handling and door openings. Factors such as space limitations, chips generated during cutting, and workpiece changes further complicate automation efforts.

ZREK's project applies proprietary AI specifically made for CNC lathe functions and integrates it with existing machinery to tackle these challenges. Enhanced automation for the chip removal process and adjustments for work changes will be standard features, paving the way for seamless unmanned operation in real-world applications.

2. Next-Gen Supply Chain for the Robotics Industry

Utilizing the local manufacturing platform 'TakaTsukuraft' in Kawasaki City, ZREK will design and develop customized frameworks and jigs optimized for small factories. The project's aim is to create user-friendly robotic solutions that fit compact spaces, easing the adoption process for SMEs.

The hardware production will be entrusted to TakaTsukuraft, operated by the Kawasaki Industrial Association, which facilitates joint procurement among companies.

On the software side, ZREK will leverage its innovative AI algorithms along with existing networks from the Kawasaki New Industry Creation Center (KBIC) to provide a comprehensive integrated implementation from infrastructure to the front end.

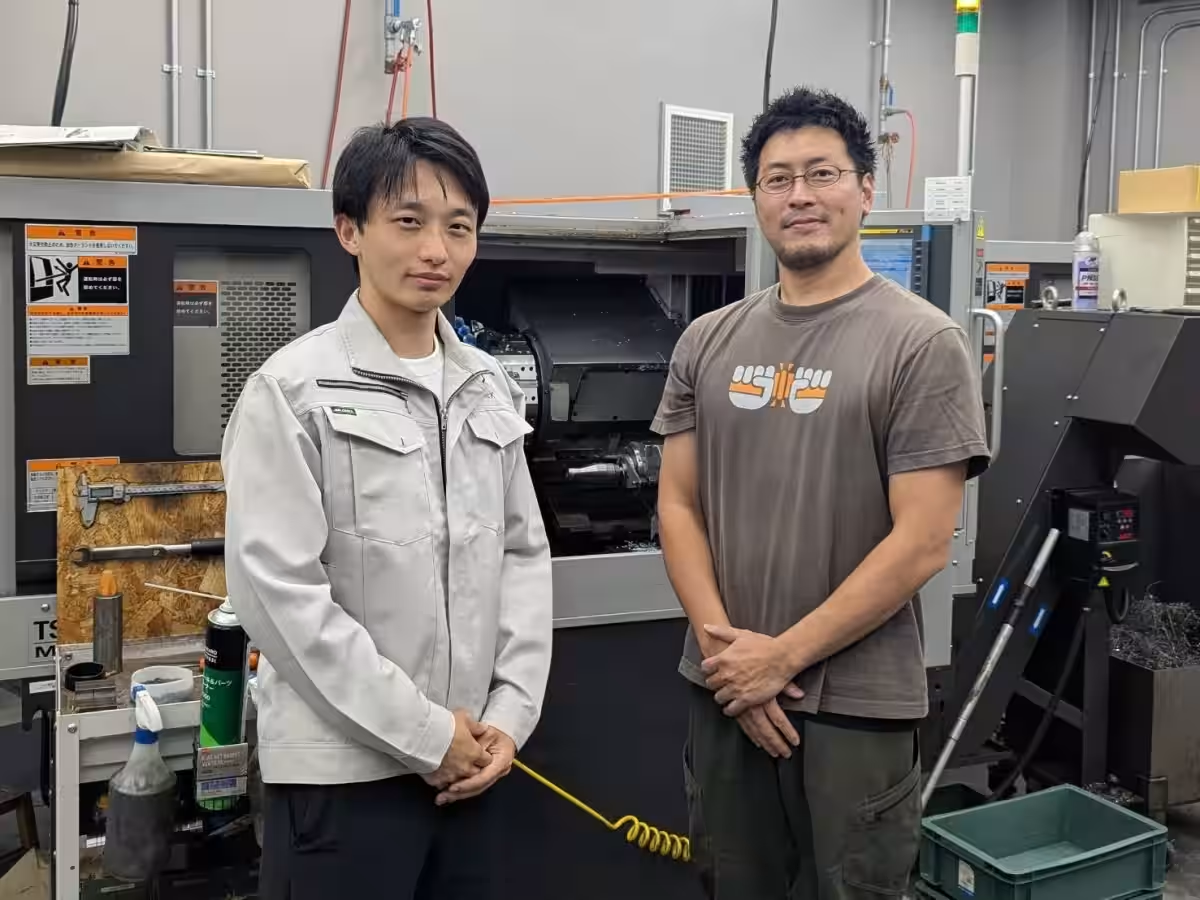

3. Maximizing Practical Utility through On-Site Demonstration

ZREK will validate its solutions in collaboration with Ohya Seisakusho, a precision metalworking company within Kawasaki. Testing will ensure the speed and accuracy of the implementation while optimizing practical use. Defining the required judgment and skills through an algorithm allows for efficient modeling of CNC lathe operations utilizing collaborative robots. This initiative further aims to extend the application of ZREK's technology to other CNC lathe machines, paving the way for

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.