Nippon Kinzoku Starts Development of Fine Profile Technology for Diverse Material Needs

Nippon Kinzoku's Innovative Approach to Fine Profile Technology

Nippon Kinzoku Co., Ltd., headquartered in Minato, Tokyo and led by President Yasushi Shimokawa, has announced the initiation of a development project focused on their Fine Profile® technology. This innovation utilizes wire materials to address the specific needs for diverse shapes and sizes in modern manufacturing.

What is Fine Profile®?

Fine Profile® is a specialized product that mainly employs strip steel, which is steel material rolled into a coil form. However, the conventional use of strip steel has limitations regarding the varieties of steel types available and technical challenges regarding quality during the cutting processes. This new approach of utilizing wire material eliminates those restrictions.

One of the key features of Fine Profile® is its contribution to resource conservation by reducing the cutting processes at the customer’s end. It is an eco-friendly product classified as an 'Eco Product', and by broadening the compatible steel types and forming ranges, it aims to enhance customer adoption rates while also contributing to carbon neutrality.

Goals for Development

With a target of commercialization set for the fiscal year 2026, Nippon Kinzoku is committed to creating innovative variants of the Fine Profile®, aligning with their 11th Management Plan titled 'NIPPON KINZOKU 2030'. This strategic vision emphasizes the effective use of diverse materials under the principles of 'Multi & Hybrid Material' and 'Near Net Shape'. These principles aim to respond to market demands for customized materials and varied shaping sizes.

Technical Advancements

The new Fine Profile® has several technical advantages:

- - Expanded Range of Steel Types: Utilizing wire materials allows for access to non-magnetic and heat-resistant steel types, thus meeting market demands better than strip steel could.

- - Increased Dimensional Range: Previously, the shaping limits were dictated by the width of the strip steel. Transitioning to using wire materials broadens these limits, minimizing waste generated during the cutting of materials and improving yield.

- - Support for Secondary Processing: By combining wire materials with cold deforming mills, the production of square bars, flat bars, and other irregularly shaped wires becomes efficient without the intermediate annealing process. This also ensures optimal coil forms for sequential pressing applications.

Specifications (In Development)

- - Dimensions: Thickness between 5 and 15mm and widths of 5 to 15mm (material diameter of less than φ16mm).

- - Product Forms: Available in either coiled or straight bar forms (up to a maximum length of 5,000mm).

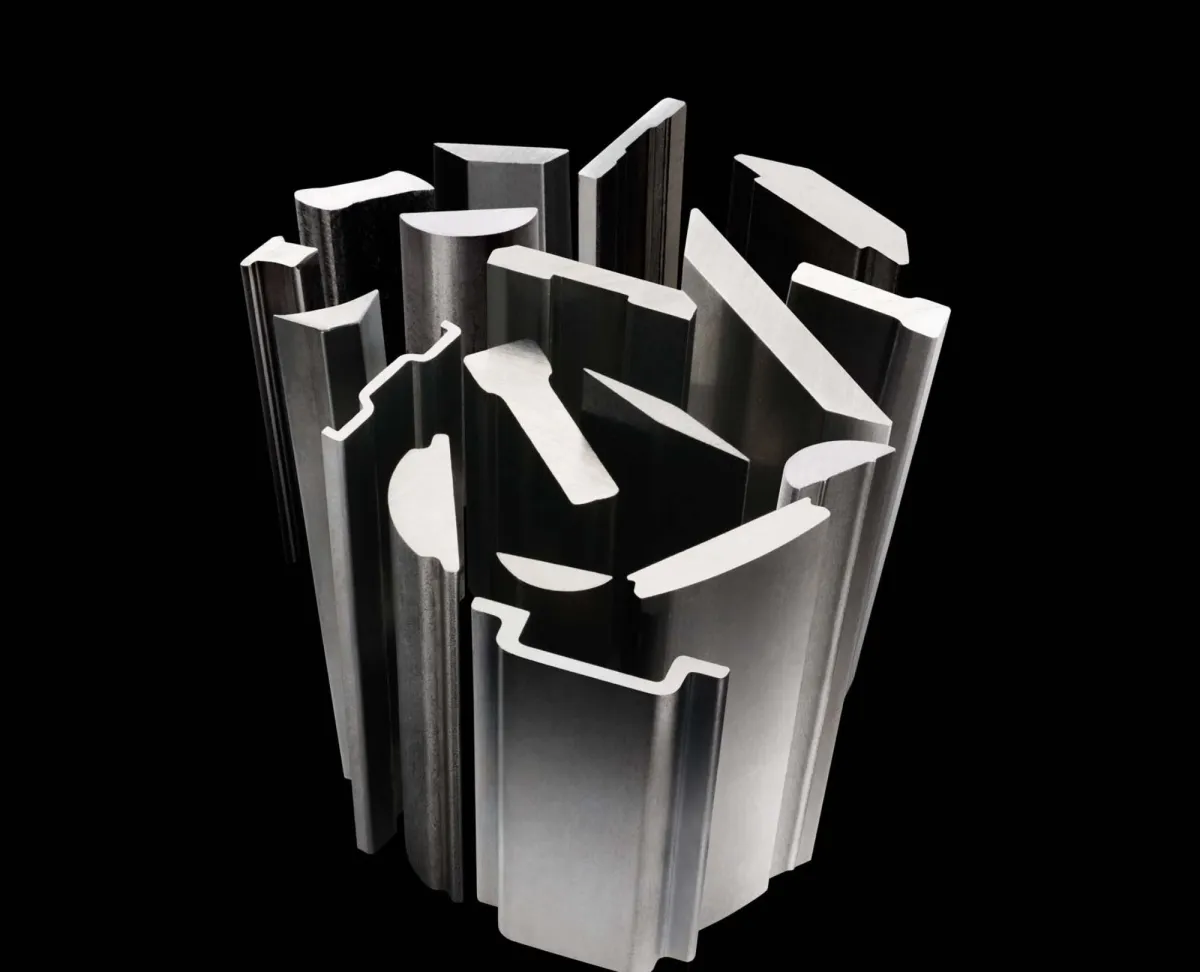

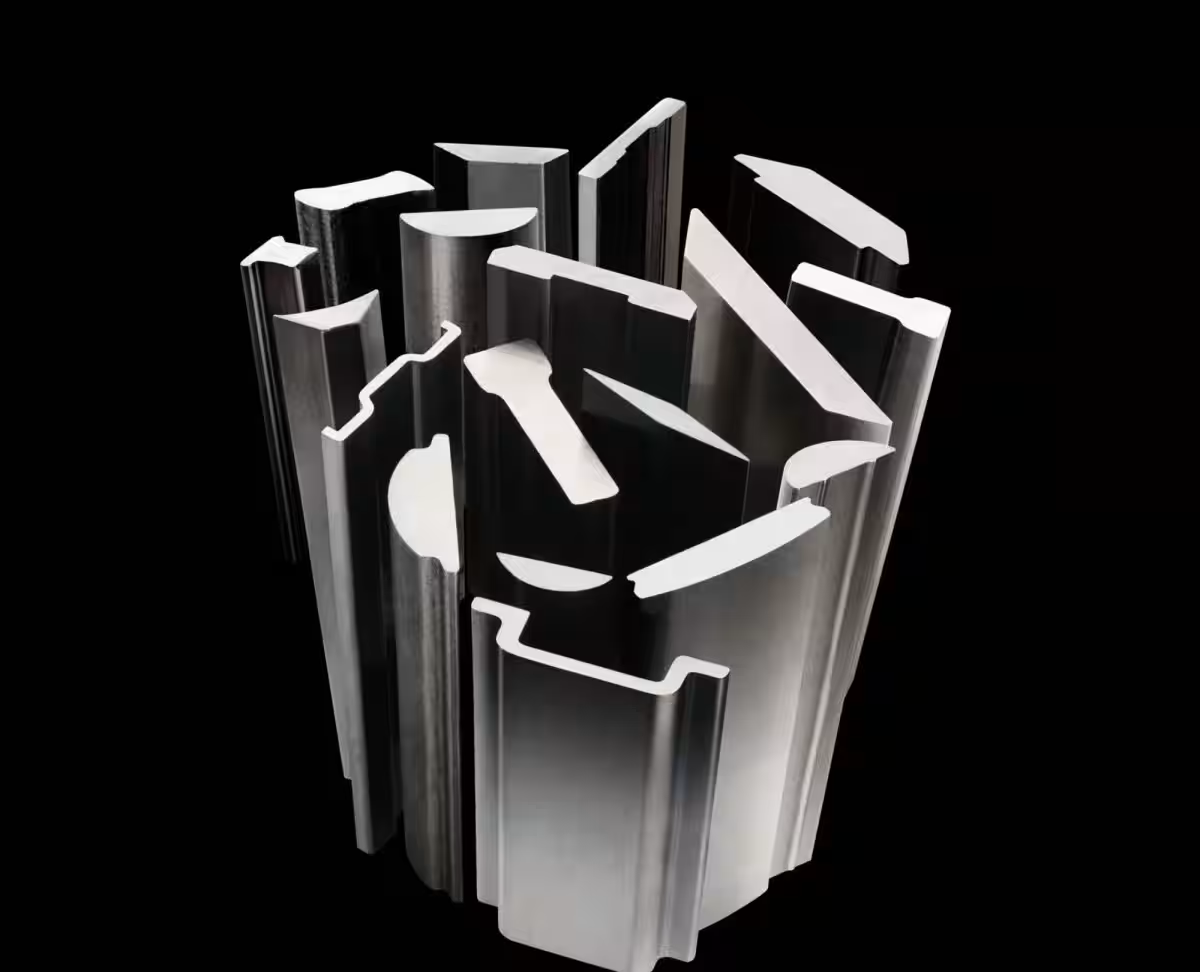

Overview of Fine Profile®

Fine Profile® refers to products crafted through unique rolling techniques, allowing for continuous processing into shapes with varying thicknesses across their width. This serves as an alternative to traditional cutting and grinding methods, contributing to reduced processing, manufacturing costs, and improved yield for clients.

For more information about the products, please visit Nippon Kinzoku's Official Website.

Note: ‘Fine Profile®’ is a registered trademark of Nippon Kinzoku Co., Ltd.

NIPPON KINZOKU 2030 Management Plan

The company's vision under this new plan is to become a Multi & Hybrid Material enterprise that co-creates value for both people and the planet. By innovating and developing products that meet the specific performance demands of final products using uniquely rolled materials, Nippon Kinzoku strives to make significant contributions to the future of humanity and our planet.

Contact Information

For inquiries about this release, please reach out to Nippon Kinzoku Co., Ltd., General Affairs Department. For questions related to technical information regarding products, contact the Production Process Support Department at 03-5765-8113 or visit their Contact Page.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.