JAL and JAXA Collaborate on Groundbreaking Riblet Coating for ZIPAIR Aircraft

Introduction

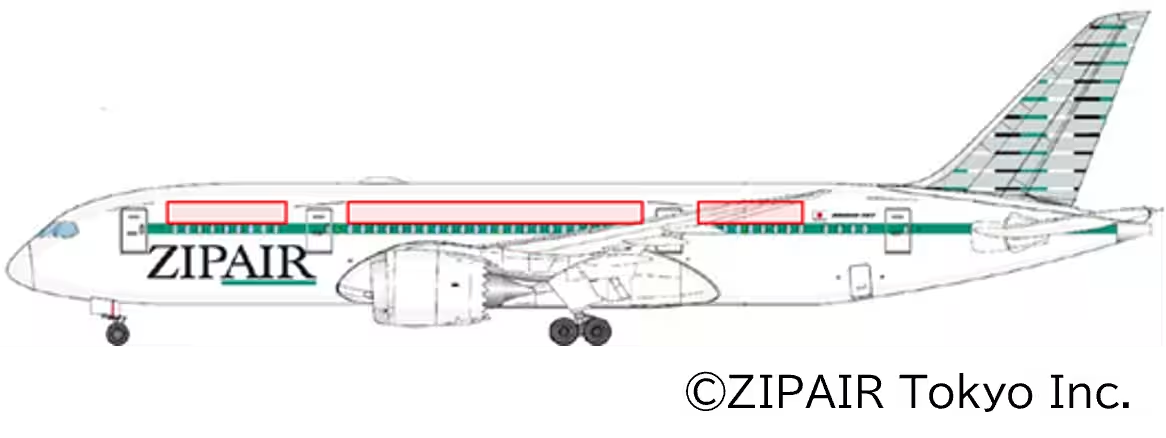

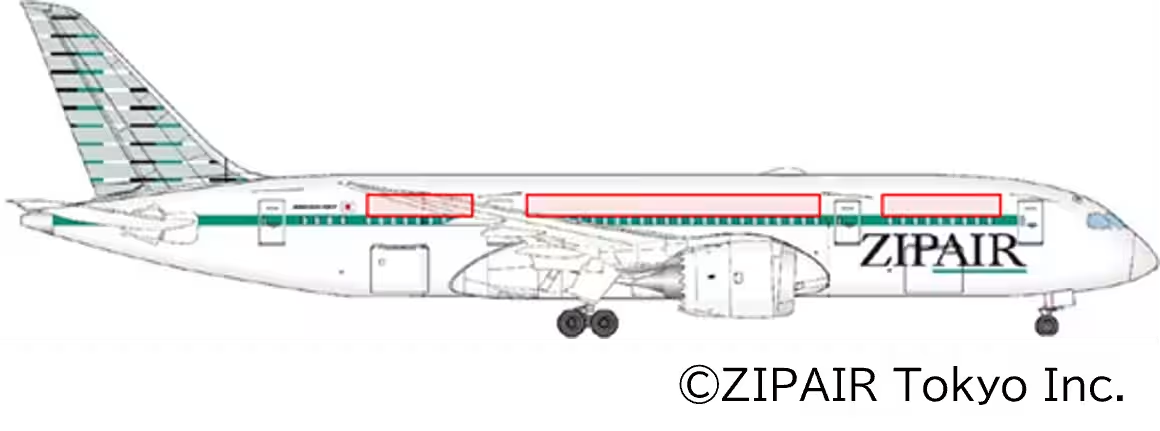

In a significant advancement toward sustainable aviation, Japan Airlines (JAL), the Japan Aerospace Exploration Agency (JAXA), and Owell Inc. have successfully applied a pioneering riblet coating on ZIPAIR's Boeing 787-8 (JA851J) aircraft. This initiative, which commenced international operations on January 27, 2026, marks a substantial step in reducing aerodynamic drag, aiming to lower fuel consumption and CO2 emissions substantially.

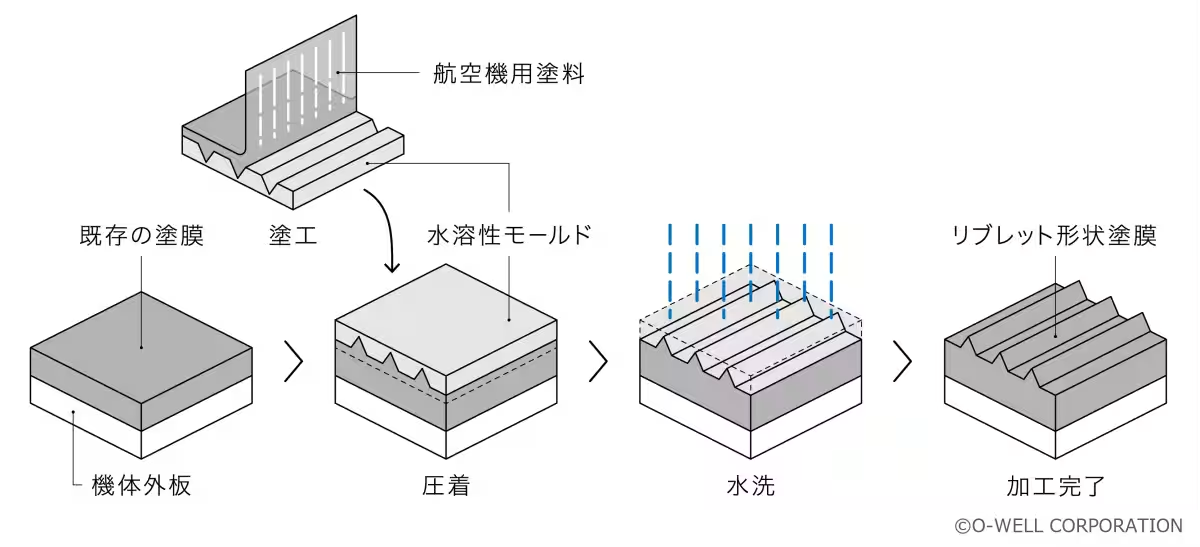

The Riblet Coating Process

The riblet texture mimics the skin of a shark, consisting of minute grooves that align with the airflow around the aircraft's body. By minimizing air resistance, the riblet design helps enhance the aerodynamic performance of the aircraft during flight. Notably, this marked the first time such a coating technique was applied to ZIPAIR's fleet, utilizing Owell's advanced Paint-to-Paint Method. This innovative method creates riblet structures on the aircraft surface while improving durability and reducing weight compared to traditional decal or film applications.

As part of the implementation, significant improvements were made in the grip tools for applying the riblet transfer sheets, as well as new positioning aids to enhance the quality and efficiency of the coating process. The project reached another milestone when it was inspected at ZIPAIR's main hub at Narita International Airport, confirming the feasibility of comparable work at Tokyo International Airport (Haneda).

Commitment to Carbon Neutrality

ZIPAIR, as JAL Group's medium- to long-haul low-cost carrier, is vocal about its commitment to carbon neutrality. The airline aims to obtain certification compliant with the international standard ISO 14068-1:2023 by May 2025. The riblet coating is part of this broader effort to reduce CO2 emissions in alignment with global sustainability goals.

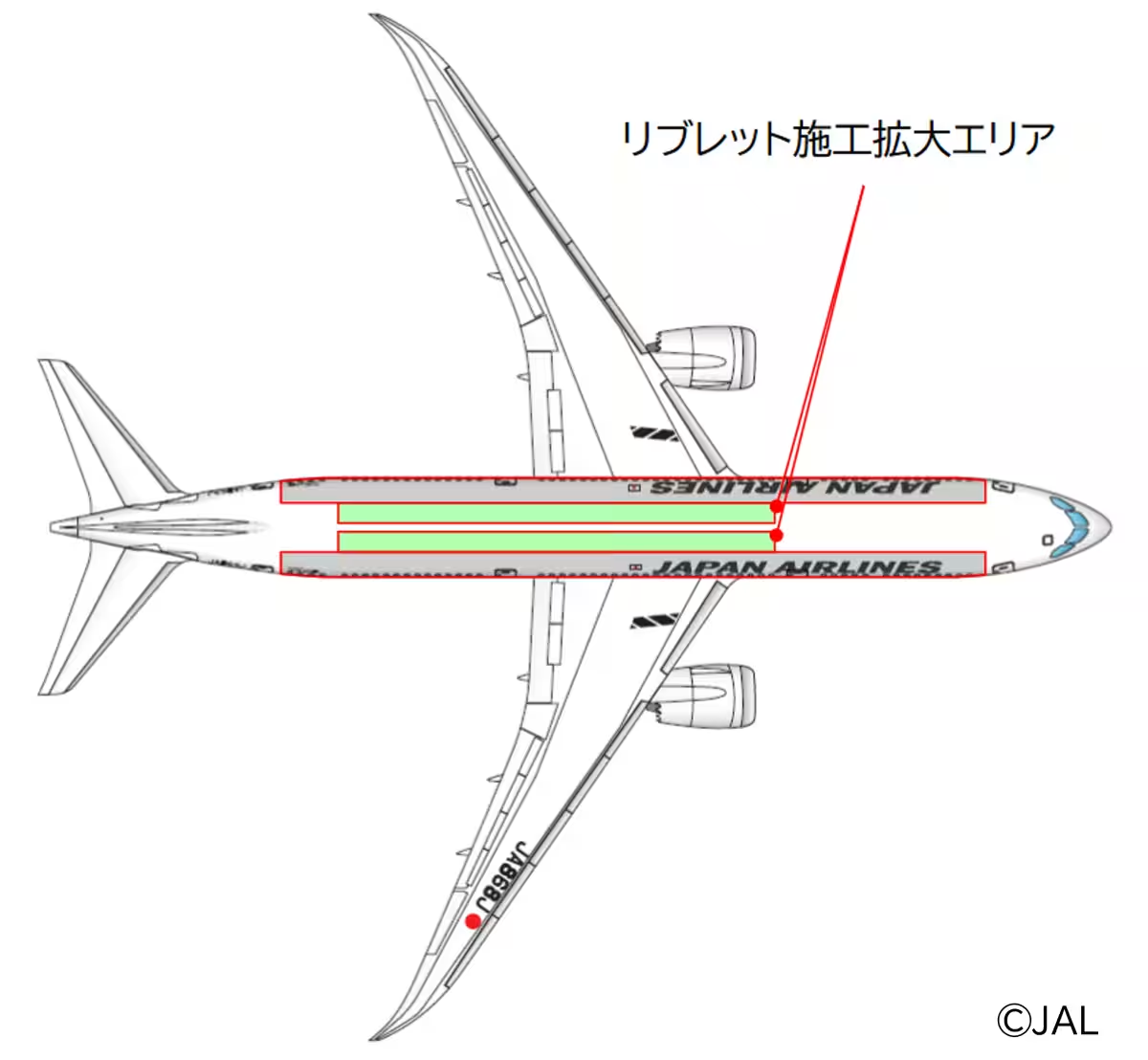

Further, JAL has been operating an additional aircraft with a riblet coating, a Boeing 787-9 (JA868J), since January 18, 2025. Plans are in place to expand this riblet application area by November 2025, thereby enhancing the airline's international operational capabilities. JAXA's resistance reduction calculations indicate an increase in cruising resistance reduction from 0.24% to 0.31% with the expanded surface area, anticipating a reduction of approximately 154 tons of fuel consumption and 492 tons of CO2 emissions annually.

Innovative Research and Development

Moreover, JAL and JAXA are not stopping here. They are also engaged in research and development of a new riblet shape, known as the sharp-edged riblet. This new design is expected to offer a friction resistance reduction rate of 6% to 6.5%, a significant improvement over the existing riblet structure.

The joint effort is part of JAXA's Space Innovation Partnership (J-SPARC), which aims to further test the durability, aesthetics, and fuel efficiency of the riblet coating on long-haul international flights. Future plans include expanding the scope of riblet application on various aircraft and improving overall sustainability in aviation.

Conclusion

The collaboration of JAL, JAXA, and Owell Inc. represents a remarkable stride toward innovative aviation solutions. Utilizing riblet coatings, airlines can significantly reduce their environmental footprint while maintaining operational efficiency. As these partnerships evolve, the airline industry can look forward to a future where sustainability and innovation go hand in hand.

References:

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.