NSK's Innovative Approach to Bearing Rebirth: Paving the Way for Sustainable Industry Practices

NSK's Innovative Approach to Bearing Renewal

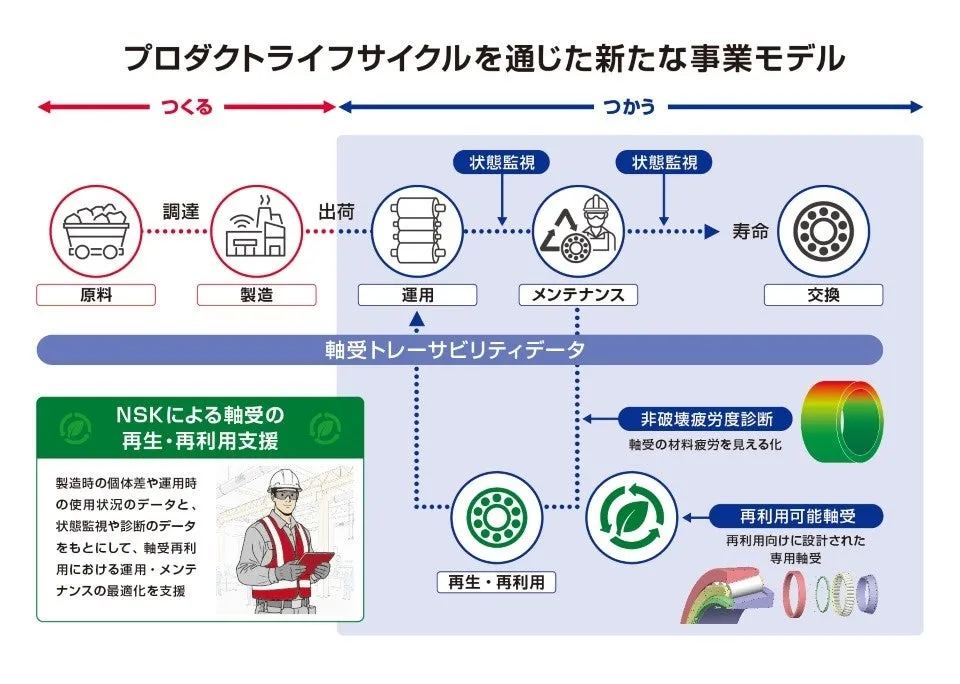

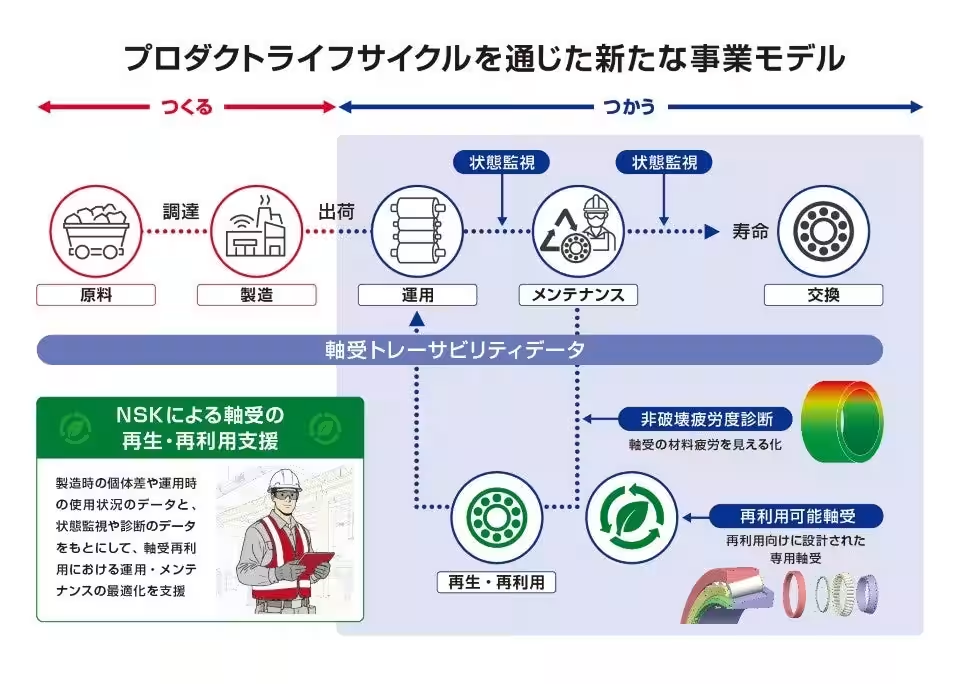

In a bold move towards achieving a carbon-neutral society, NSK Ltd., headquartered in Shinagawa, Tokyo, is embarking on a transformative journey focused on recycling and reusing bearings. With the leadership of President and CEO Akitoshi Ichii, the company is exploring a new business model that facilitates collaboration with customers throughout the product lifecycle, from maintenance and repair to disposal.

Background and Challenges

In industries such as steel manufacturing, paper production, and mining, bearings are routinely removed from equipment for maintenance. They undergo a process of disassembly, thorough cleaning, and inspection, followed by necessary repairs, before being reinstalled for continued use. However, many bearings generate significant CO₂ emissions during manufacturing, making it essential to maximize their lifespan. The challenge lies in the lack of straightforward methods available on-site for maintenance personnel to assess the remaining lifespan of bearings accurately. Consequently, bearings that still have potential utility are often discarded prematurely to ensure stable equipment operation.

Moreover, the reliance on visual assessments by aging technicians introduces variability in evaluation precision, exacerbating the difficulty in passing on essential skills and knowledge.

NSK's Innovative Solution

To address the hurdles of bearing renewal and reuse, NSK has developed a unique non-destructive fatigue diagnostic technology. This innovation enables quick and accurate onsite assessments of bearing fatigue without causing any damage. Furthermore, NSK is advancing the development of a new design philosophy, termed

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.