ZIPAIR Implements Innovative Riblet Coating for Reduced Fuel Consumption and Emissions

Introduction

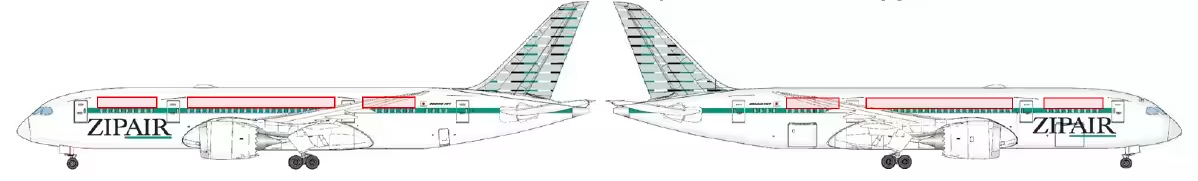

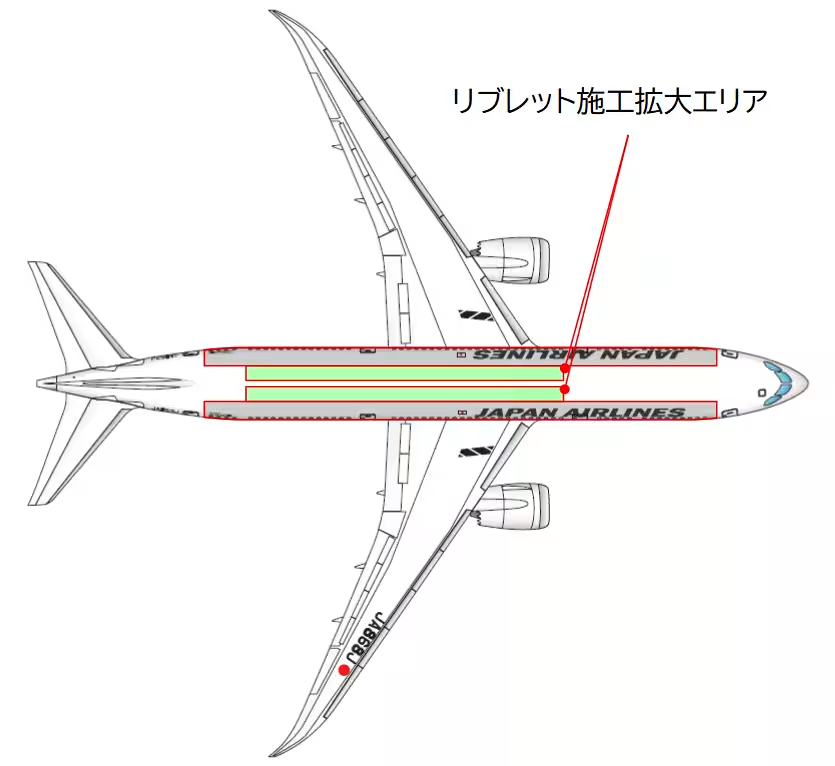

In a significant step towards sustainability, ZIPAIR has recently launched the application of riblet-shaped coatings on its Boeing 787-8 aircraft (JA851J). This initiative was undertaken in partnership with Japan Airlines (JAL), the Japan Aerospace Exploration Agency (JAXA), and Owell Inc. The innovative riblet coating began international operations on January 27, 2026, and aims to minimize aerodynamic drag, ultimately reducing fuel consumption and CO2 emissions.

What are Riblet Coatings?

Riblet coatings, inspired by the skin of sharks which effectively reduce water resistance, feature a unique micro-grooved structure designed to enhance airflow around aircraft surfaces during flight. By applying these coatings to the aircraft's exterior, the aim is to achieve a remarkable decrease in aerodynamic resistance.

The Collaborative Effort

The project represents a collaboration among prominent organizations: JAL, JAXA, and Owell, with JAXA leading the research on riblet technology. As part of its commitment to sustainability, ZIPAIR acquired carbon neutrality certification compliant with the international standard ISO 14068-1:2023 in May 2025. The riblet application is a vital element of this certification, supporting ongoing initiatives to mitigate CO2 emissions.

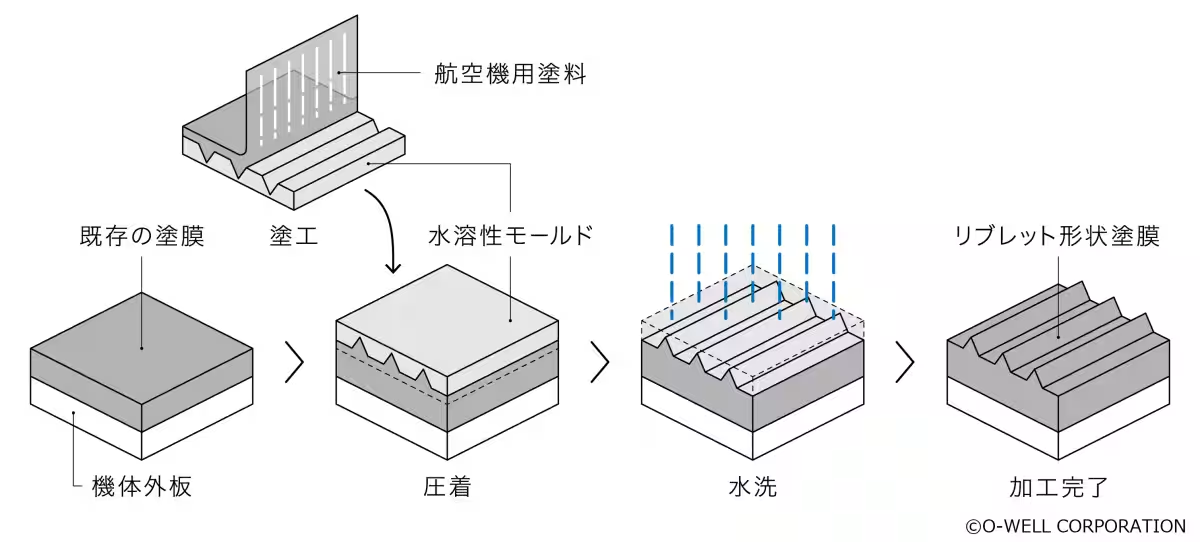

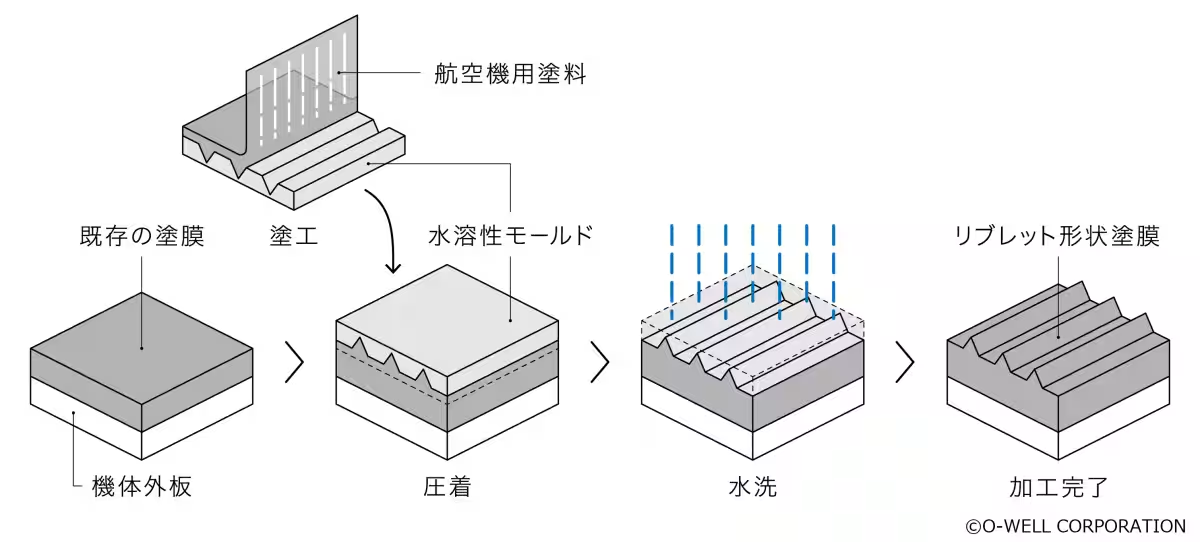

Paint-to-Paint Method

The riblet application on ZIPAIR was accomplished using Owell's refined "Paint-to-Paint Method". This technique facilitates the formation of riblet patterns directly onto existing paint surfaces, enhancing durability and reducing weight compared to traditional decal or film methods. With the recent improvements in riblet transfer tools and positioning supports, work efficiency and quality have significantly improved, ensuring successful application in ZIPAIR's hangar at Narita International Airport.

Expected Benefits

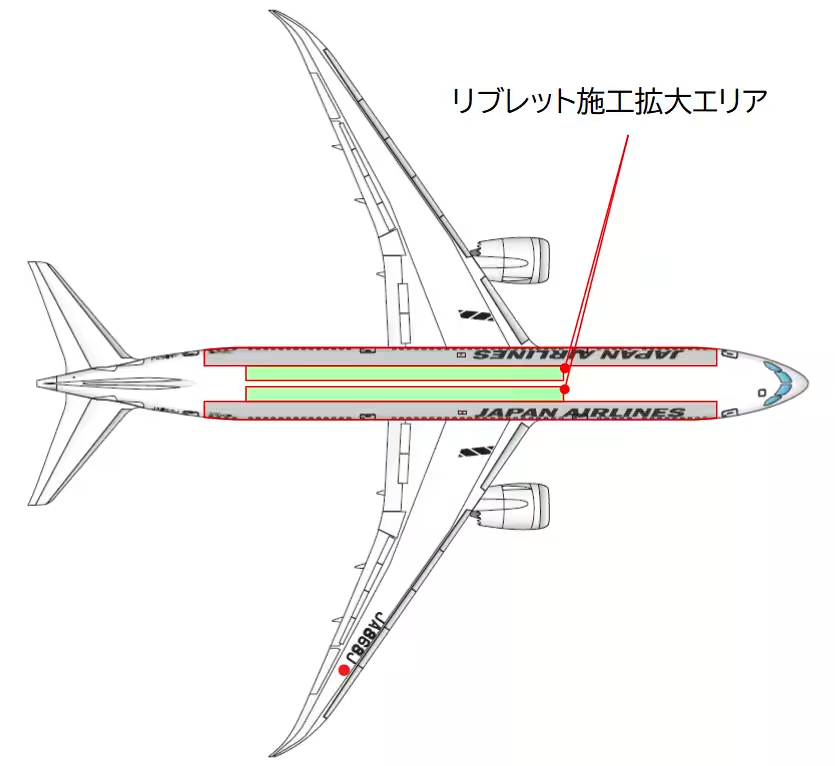

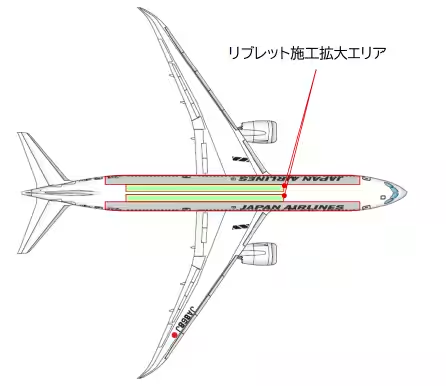

As a result of implementing the riblet coatings, ZIPAIR anticipates improved fuel efficiency and reduced emissions on its international flights. According to calculations derived from JAXA's riblet resistance reduction technology, extending the riblet application on the upper fuselage could optimize the drag reduction rate from 0.24% to 0.31% during cruise. This enhancement is projected to save approximately 154 tons of fuel and reduce CO2 emissions by about 492 tons annually.

Future Innovations

Further advancements are underway, including research and development of enhanced riblet shapes, such as sharp-edged riblets, which promise even greater drag reduction capabilities. The ongoing exploration into the durability of these riblet coatings under flight conditions will be vital for wider implementation across various aircraft.

Continuous Verification and Expansion

This initiative is part of the JAXA Space Innovation Partnership (J-SPARC) collaborative demonstration project. The ongoing efforts will focus on verifying the durability and aesthetic aspects of the riblet coatings, while continuously assessing fuel economy benefits on long-haul international routes. The goal is to expand the aircraft types and application areas to further enhance sustainability in aviation.

Conclusion

ZIPAIR's adoption of riblet coatings is an essential step toward achieving decarbonization in aviation. By leveraging innovative technologies and collaboration with leading aerospace organizations, ZIPAIR is setting new benchmarks in fuel efficiency and emissions reduction while pushing the boundaries of sustainable air travel.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.