Trina Solar's Seminar at TECHNO-FRONTIER 2025: Leading Innovations in Renewable Energy

Trina Solar's Impact at TECHNO-FRONTIER 2025

Trina Solar Co., Ltd., a leader in the solar energy sector, made a significant impact at the recent TECHNO-FRONTIER 2025 event held at Tokyo Big Sight from July 23 to 25, 2025. On July 25, the company hosted a seminar focusing on the theme of "Harnessing Renewable Energy to Support Manufacturing in the Carbon Neutral Age." This event not only highlighted Trina Solar's innovative products and case studies but also emphasized its efforts in ESG (Environmental, Social, and Governance) management and the decarbonization of its manufacturing processes.

During the seminar, Trina Solar engaged with numerous attendees, reflecting the rising interest in decarbonization and renewable energy within the manufacturing sector. The exchange of ideas and experiences further deepened attendees' understanding and potential applications of Trina Solar’s solutions.

Trina Solar's Commitment to Green Management

Trina Solar takes a holistic approach to business management, promoting a philosophy of "Green Development" that underpins its corporate activities. This initiative aims for sustainable growth while minimizing environmental impact. In 2024, Trina Solar became a member of the United Nations Global Compact and received high evaluations from ESG rating organizations such as CDP, which assesses climate change measures, and MSCI, which analyzes corporate sustainability.

Furthermore, the company is actively pursuing a "Zero Carbon Value Chain" initiative that extends beyond Scope 1 and 2 emissions to encompass its entire supply chain. This ambitious goal highlights Trina Solar's dedication to comprehensive decarbonization.

Products and Domestic Implementation Cases Supporting Decarbonization

During the seminar, Trina Solar presented its latest product offerings that contribute to reducing environmental burdens, along with successful implementations within Japan’s manufacturing sector. One notable solution is the combined solar and storage integrated energy solution, which addresses diverse needs, such as BCP (Business Continuity Planning) compliance, energy independence, and cost reduction.

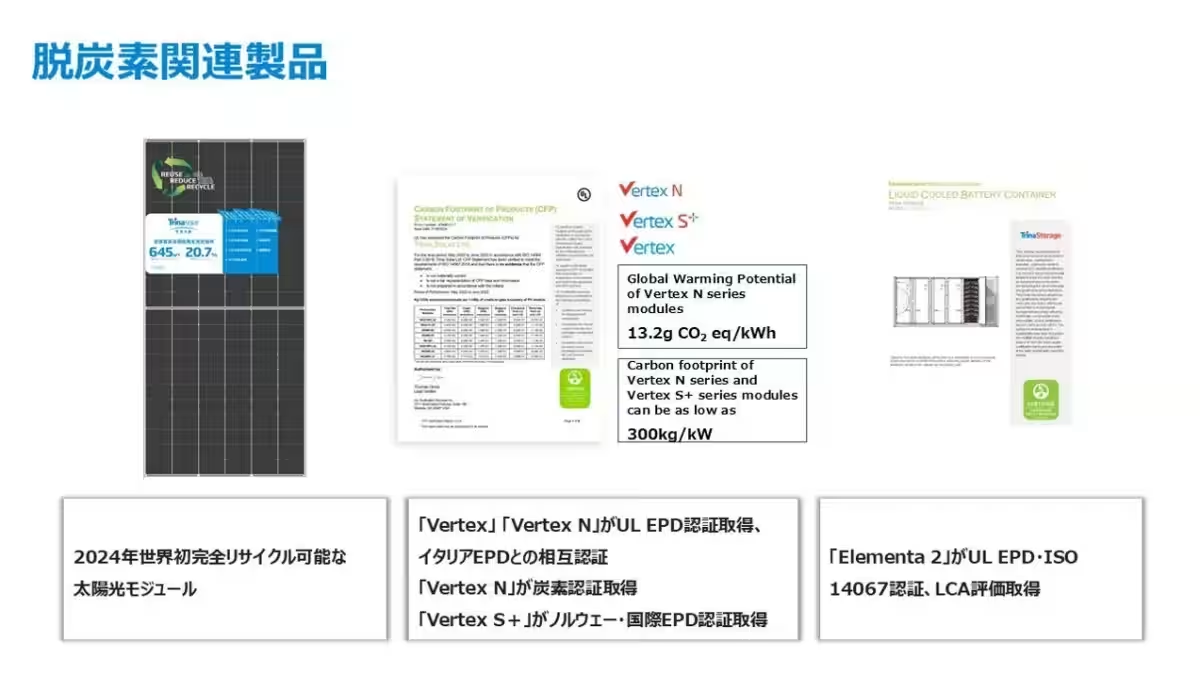

Key product features include:

- - Solar Modules: Utilizing 100% renewable resources, achieving over 645W output and converting efficiency of 20.7%, exemplifying high performance and environmental consideration.

- - Vertex N Series: Certified for carbon footprint in France and UL certified in the U.S., achieving low CO₂ emissions of 13.2g CO₂eq/kWh from manufacturing through disposal.

- - Vertex S+ Series: Obtained Norwegian and international EPD (Environmental Product Declaration) certification, quantifying and visualizing the environmental impact of each product.

- - Elementa 2: An industrial-scale storage system that received the industry's first EPD certification ensuring a 20-year life cycle, aiding in peak power reduction and increasing renewable energy self-consumption rates.

Specific examples of successful implementations of solar energy in Japan’s manufacturing facilities include:

- - Factory in Shizuoka: Implementation of a PPA model utilizing factory roofs and carports to realize solar power generation while minimizing initial investment.

- - Okabe New Energy: Introduced a self-consumption type solar power system installed on the ground at its industrial facility.

- - Alvorex, a materials manufacturer: Installed Vertex S+ modules on the factory roof to achieve both cost reduction and environmental impact mitigation.

These efforts signify a shift in how renewable energy is viewed—not merely as an environmental strategy, but as a means to enhance corporate competitiveness.

For a closer look at the solar implementation cases discussed in the seminar, videos are available showcasing:

- - PPA Case Study in Shizuoka Factory with Vertex TSM-DE19R and DEG19RC.20

- - Ground Installation at Okabe New Energy’s Facility with Vertex N TSM-NEG19RC.20

- - Roof Installation at Alvorex Factory using Vertex S+ TSM-NEG18R.28

Initiatives towards Zero Carbon in Trina Solar's Factories

Beyond providing renewable energy solutions, Trina Solar is committed to advancing decarbonization within its own manufacturing facilities. These initiatives focus not only on immediate reductions in Scope 1 and 2 emissions but also on realizing a future Zero Carbon Value Chain, serving as a notable example of sustainable manufacturing.

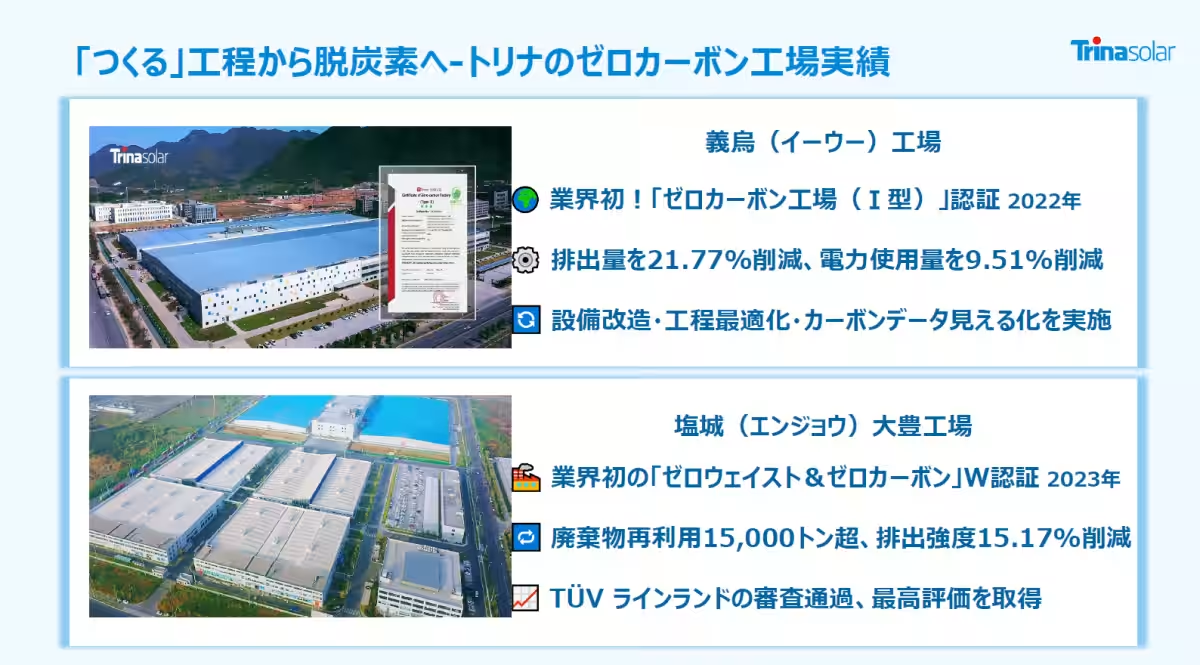

Yiwu Factory (China)

In 2022, Trina Solar became the first in the solar industry to obtain the "Zero Carbon Factory (Type I)" certification. Through equipment improvements and optimized processes, the plant reduced greenhouse gas emissions by 21.77% year-on-year and energy usage by 9.51%. It has also achieved international standards like ISO 14064 (Greenhouse Gas Management) and ISO 50001 (Energy Management).

Yancheng Daitou Factory (China)

In 2023, this facility earned TÜV Rheinland's "Zero Carbon" and "Zero Waste" dual certification, successfully reusing over 15,000 tons of waste annually and cutting emission intensity by 15.17% year on year.

This seminar underscored the increasing interest in renewable energy utilization and decarbonization within the manufacturing sector. Trina Solar is committed to delivering solutions tailored for the Japanese market, thereby contributing to the establishment of a sustainable society.

About Trina Solar (SH Stock Code: 688599)

Founded in 1997 as an integrator of solar energy systems, Trina Solar is a global leader in providing comprehensive solar photovoltaic and smart energy solutions. The company operates in over 170 countries with a strategic goal of creating a new industrial ecosystem centered around solar energy and supporting power system reforms for a zero-carbon future.

In Japan, Trina Solar Japan was established in 2010 and has since delivered cutting-edge full-line products tailored to local demand, achieving numerous successful partnerships and projects.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.