Precision Parts Manufacturer Adopts MISUMI floow for Enhanced Efficiency

Introduction

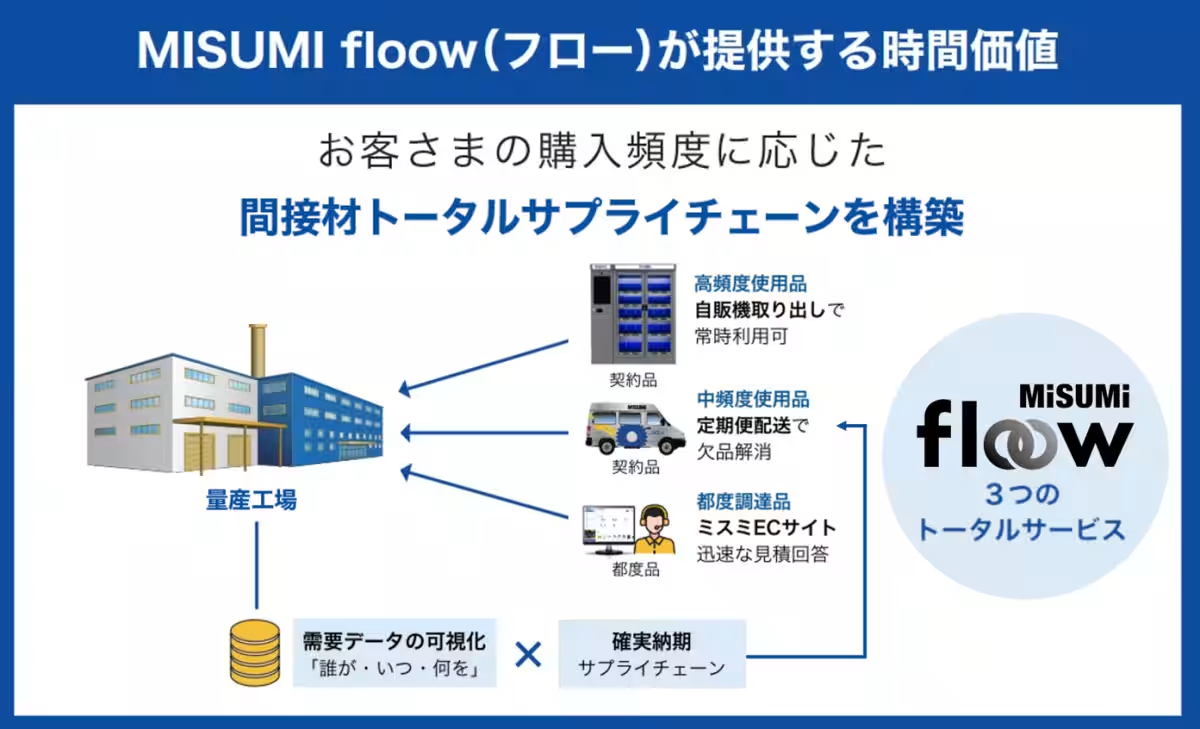

The adoption of innovative technologies in manufacturing continues to revolutionize the industry. A remarkable example can be seen in the deployment of MISUMI floow by a precision parts manufacturing company, which specializes in the automotive, aerospace, and energy sectors. This service, offered by the MISUMI Group, focuses on reducing indirect material costs and enhancing overall operational efficiency.

Overview of the Company

The company, known as 放電精密加工研究所 (Discharge Precision Processing Institute), is located in Yokohama, Kanagawa Prefecture, and has built a reputation for its high-precision manufacturing capabilities using discharge machining technology. This institute produces essential components for a wide array of industries, including automotive, aerospace, and energy.

Historically, the company managed consumable supplies using paper-based purchase request forms. This reliance on manual processes has placed significant operational burdens both on the site and management teams.

Challenges Faced

The existing system led to difficulties such as excessive inventory due to the fear of stock shortages and human error stemming from personal responsibility in order management. The employees were forced to count inventory weekly, which disrupted workflow and added unnecessary stress to their tasks.

To address these challenges, the implementation of MISUMI floow was initiated. This innovative solution merges automated vending services with automated replenishment by MISUMI, significantly reducing the workload related to ordering and replenishing supplies and propelling the company towards a paperless and efficient operation.

Improvements with MISUMI floow

With the implementation of this system, the company has successfully eliminated the need for paper-based processes, decreasing the workload for both on-site staff and management. The standardization of operations has been realized, thereby minimizing human error and streamlining overall workflow.

The previous routine of maintaining excess stocks to preempt shortages has been replaced by a reliable solution. Now, employees can access necessary supplies directly from vending machines, efficiently supplied by MISUMI. This transition not only mitigates surplus inventory issues but also frees up storage space within the company's facilities, enhancing physical working conditions.

Additionally, the vending machines are user-friendly and are readily accepted by the employees, integrating seamlessly into their daily routines.

Data Visibility and Continuous Improvement

One key advantage of MISUMI floow is its ability to visualize usage history. The dashboard presents analytics on product usage and cost-saving metrics, thus allowing for informed decision-making regarding inventory management. The company can now conduct thorough analyses on product performance and assess why specific sizes or types are favored. This data-driven approach makes it easier to adapt product offerings and refine shelf layouts.

Feedback from the Team

According to T.K., the head of the Komaki Manufacturing Department,

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.