Achieving 93% Field Satisfaction with Smart Inventory Management Solutions

Achieving Efficiency in Inventory Management at Mitsubishi Chemical's Tokai Plant

In an impressive demonstration of digital transformation, the SmartMat Cloud system, developed by Esmat Co., Ltd., has been implemented at Mitsubishi Chemical Corporation's Tokai plant in Japan. The innovative IoT inventory management solution is helping to ensure operations run smoothly by minimizing risks associated with inventory shortages that could halt essential inspection work.

Background of Implementation

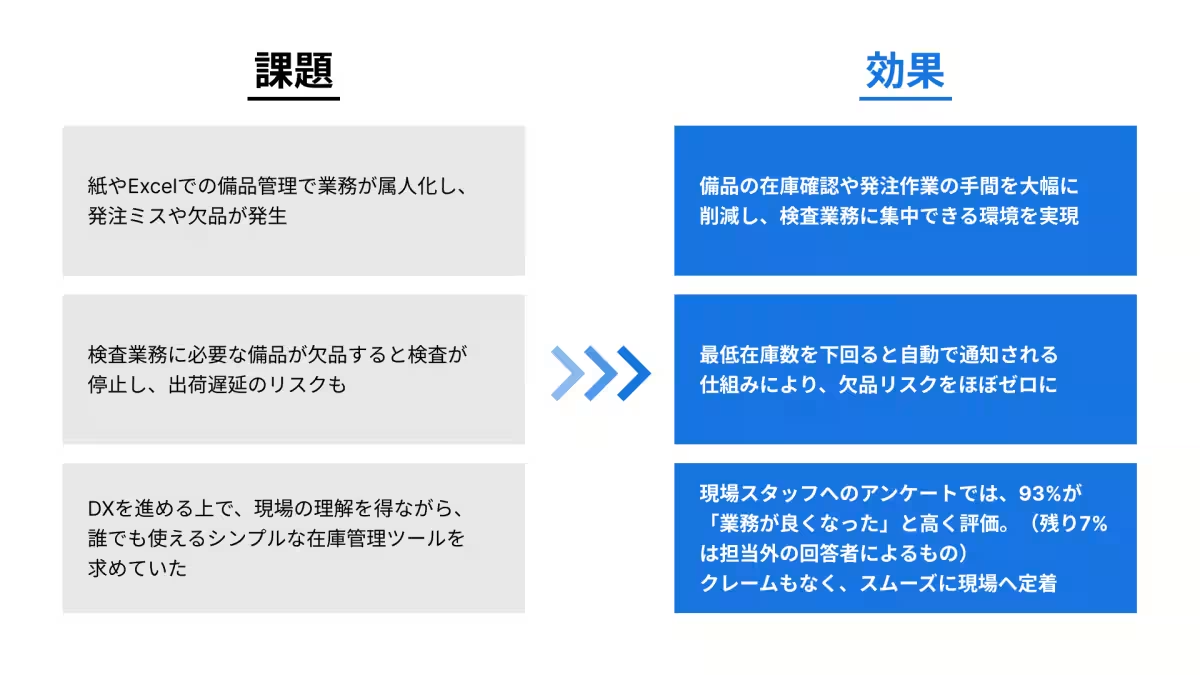

Mitsubishi Chemical's Tokai facility, known for being Japan's first integrated chemical complex, has undergone a significant evolution recently. While grappling with inefficiencies in inventory management that were primarily reliant on paper and Excel spreadsheets, it faced challenges such as personnel dependency in stock confirmations and ordering processes. This old system was not only time-consuming but also posed the risk of inventory depletion, which could lead to temporary suspension of critical inspection operations. Especially for indispensable items such as safety gloves, this could mean widespread interruptions in workflow, making efficient inventory management a pressing concern.

Transition to Smart Inventory Management

Esmat's SmartMat Cloud system offers a sophisticated yet user-friendly solution to these complex problems. By visualizing real-time stock through IoT technology, it automates inventory management processes, allowing for significant reductions in human resource involvement. This transition to digitization not only simplifies the tasks related to inventory checks and ordering but also helps maintain seamless operations—especially vital in a high-stakes environment such as chemical manufacturing.

Since its launch in winter 2018, SmartMat Cloud has been integrated across various sectors from manufacturing to healthcare, showcasing its flexibility and wide applicability. Over 1,200 companies have already adopted this SaaS platform, witnessing remarkable transformations in their inventory management practices.

Achievements and Staff Satisfaction

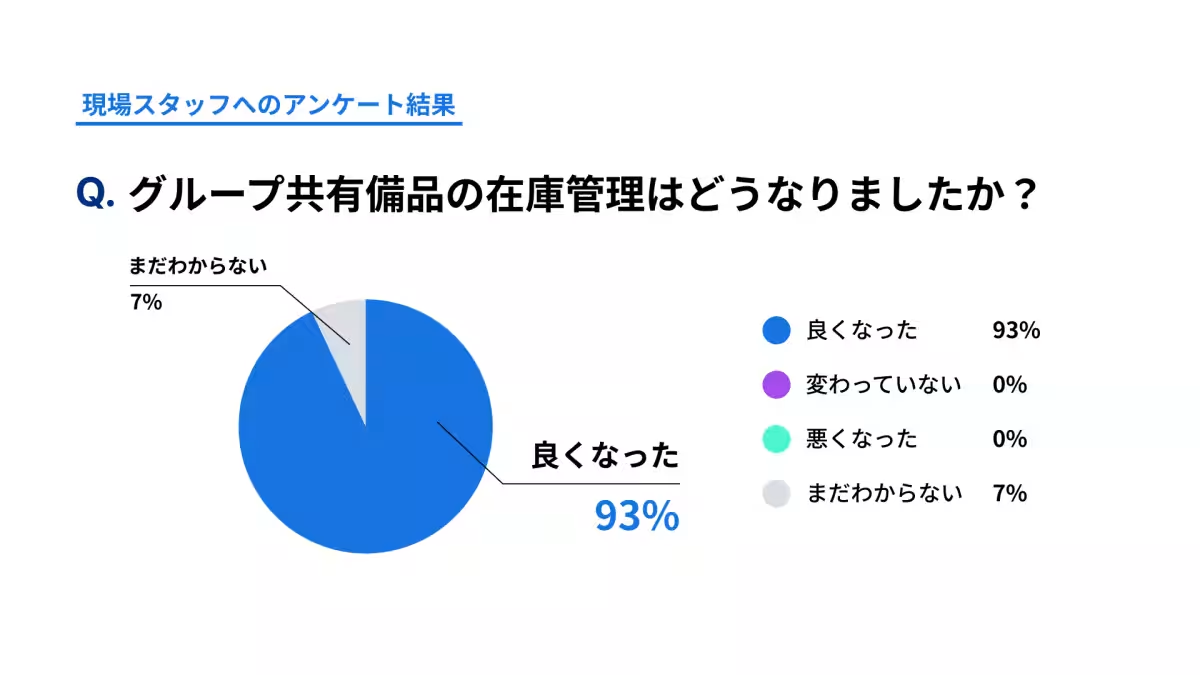

The results of the transformation at Mitsubishi Chemical's Tokai facility are telling. A survey conducted among the frontline staff revealed that an impressive 93% felt that their work environment had improved following the implementation of SmartMat Cloud.

Conclusion

This case study exemplifies how the integration of advanced digital solutions like SmartMat Cloud can revolutionize inventory management practices, boosting operational efficiency, reducing risk, and enhancing workplace satisfaction. For companies looking to modernize their inventory systems, Esmat's innovative approach stands as a prime example of how technology can facilitate a smoother, more reliable operational flow.

For more details on the case, visit SmartMat Cloud Case Study.

For more information on Esmat Co., Ltd. and its products, please check their official website Esmat Co., Ltd..

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.