Innovative Offline Inspection Feature Debuts at FOODEX JAPAN 2026

Introduction

Miroku-create Co., Ltd., located in Nankoku City, Kochi, has announced the debut of its innovative offline inspection option, Miroku AI Offline Inspection (alpha version), at the upcoming FOODEX JAPAN 2026. This event is set to take place from March 10 to 13, 2026, at Tokyo Big Sight, and will showcase the next generation of equipment maintenance solutions through cloud technology.

What is Miroku AI Offline Inspection?

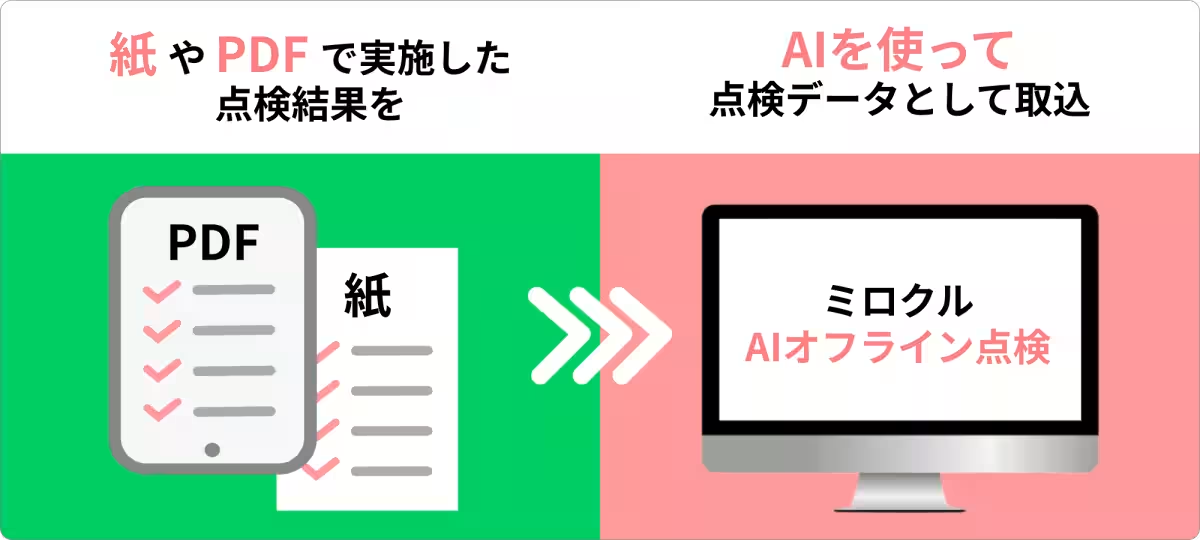

The Miroku AI Offline Inspection is the third extension of Miroku-create's AI options, which began with Miroku AI Maintenance Navigator in October 2025 and followed by the Miroku AI Help Chat in January 2026. This latest feature aims to revolutionize inspection tasks that are traditionally carried out on paper or PDFs by leveraging Generative AI to digitize inspection results. With this system, results are no longer dependent on connectivity, allowing for seamless digital management of inspections even in offline environments.

Key Features

Digitizing Paper Inspections

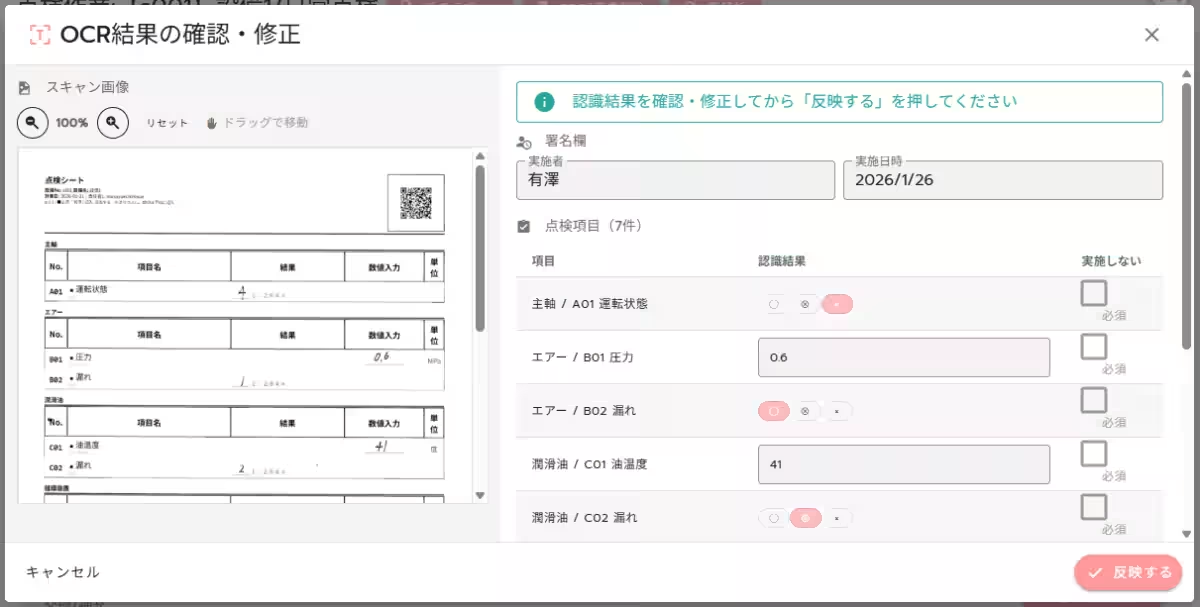

The Miroku AI Offline Inspection simplifies the data entry process by reading printed inspection results from paper forms and PDFs, converting them into compatible inspection data for the Miroku Cloud platform. Users can simply write on a designated paper format or fill out a provided PDF template, and once completed, they can upload these documents using the PDF Batch Scan function. The system's AI will analyze and automatically convert the recorded information into the appropriate format, similar to that of conventional digital entries. Users even have the ability to review and modify the scanned results before finalizing them, reducing the risks associated with data entry errors.

Offline Functionality

This innovative solution is designed with the needs of workplaces that face restrictions on equipment usage in mind, particularly in hazardous areas or locations with unstable internet connectivity. By allowing users to record their inspections on paper and later digitize the data, it meets the necessity for paper usage in various operational contexts.

Reliable AI Integration

The AI's reading capabilities and the option for users to confirm and edit the extracted data considerably lower the risks associated with false recognition, ensuring a reliable operation. By incorporating flexibility to adapt to the realities of the workplace, Miroku AI Offline Inspection promotes efficient data accumulation and management while respecting existing procedural workflows.

Additional Information

During the FOODEX JAPAN 2026 exhibition, Miroku-create will be featured in the Startup Zone, showcasing how their solutions provide new value to the food industry. Attendees can expect hands-on experiences with operational simulations and specific use-case demonstrations that highlight the transformative potential of the Miroku AI features.

Seminar Presentation

Additionally, on March 10, 2026, Miroku-create will conduct a pitch presentation titled “Revolutionizing Maintenance: The Miroku Approach to Building Strong Teams with Fewer Resources”. This will address how relying solely on traditional maintenance methods is no longer viable, particularly in contexts like food manufacturing. The pioneering strategies discussed will gear towards utilizing digital transformation for stable production amidst ongoing labor challenges.

Conclusion

In a rapidly evolving industry, Miroku Cloud stands out as an essential tool that meets the pressing need for innovative maintenance solutions. By effectively utilizing the expertise from various sectors, the Miroku solutions seek to empower organizations to move confidently into the digital age of maintenance, ensuring sustainable growth and efficiency.

For more details, visit Miroku-create's official webpage.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.