Kyushu Yanagawa Seiki Company Revolutionizes Operations with i-Reporter to Achieve Dramatic Efficiency Gains

Introduction

Kyushu Yanagawa Seiki Co., Ltd., a leading automotive parts manufacturer based in Kumamoto Prefecture, Japan, has successfully embraced digital transformation by implementing the innovative field report system 'i-Reporter'. In collaboration with Shimtops Co., Ltd., the provider of i-Reporter, Kyushu Yanagawa Seiki has streamlined its operations across four key areas, achieving remarkable efficiency gains and significantly reducing labor costs.

Background and Challenges

Founded in 1976, Kyushu Yanagawa Seiki specializes in the production of aluminum die-cast components for vehicles, covering everything from casting to painting and assembly. Despite its robust business model, the company faced significant challenges as many on-site operations were paper-based. This led to:

- - Work Reports: Collecting and inputting about 190 work reports took approximately six hours a day.

- - Painting Line Management: Monitoring a 200-meter painting line's progress was time-consuming, adversely affecting preparations for subsequent processes.

- - Equipment Dispatch Recording: Monthly input and aggregation of equipment dispatch data required an average of 2.5 hours per month.

- - Change Point Management Boards: Daily saving of photos of 23 management boards also consumed about one hour.

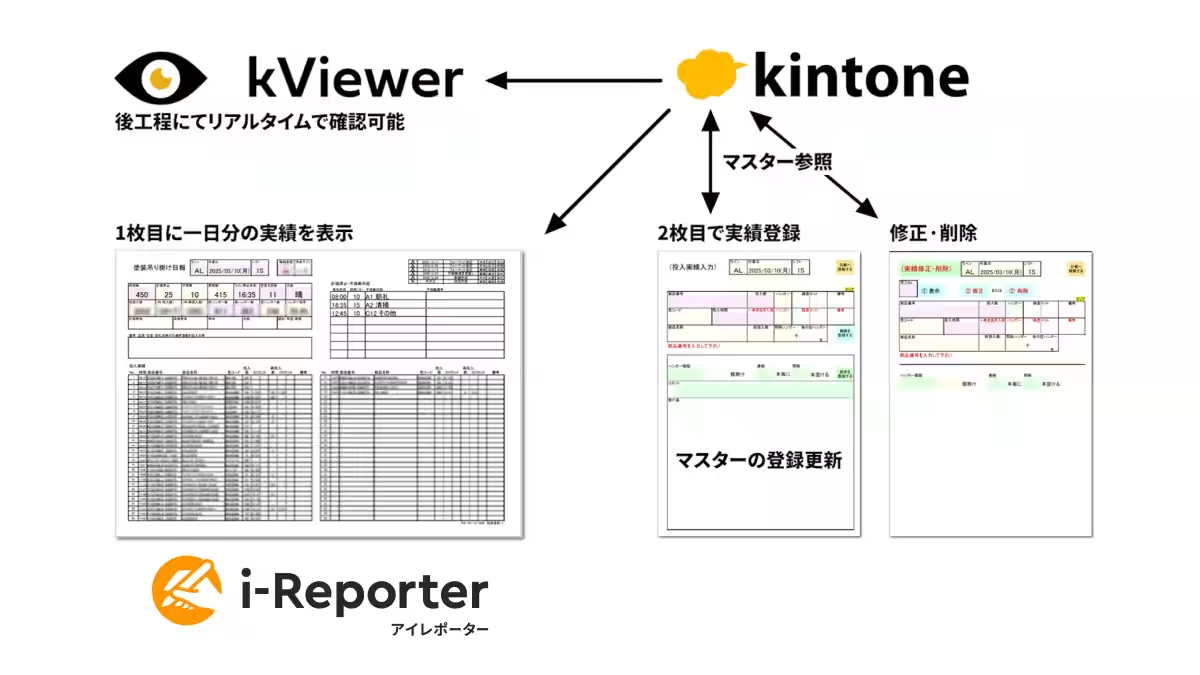

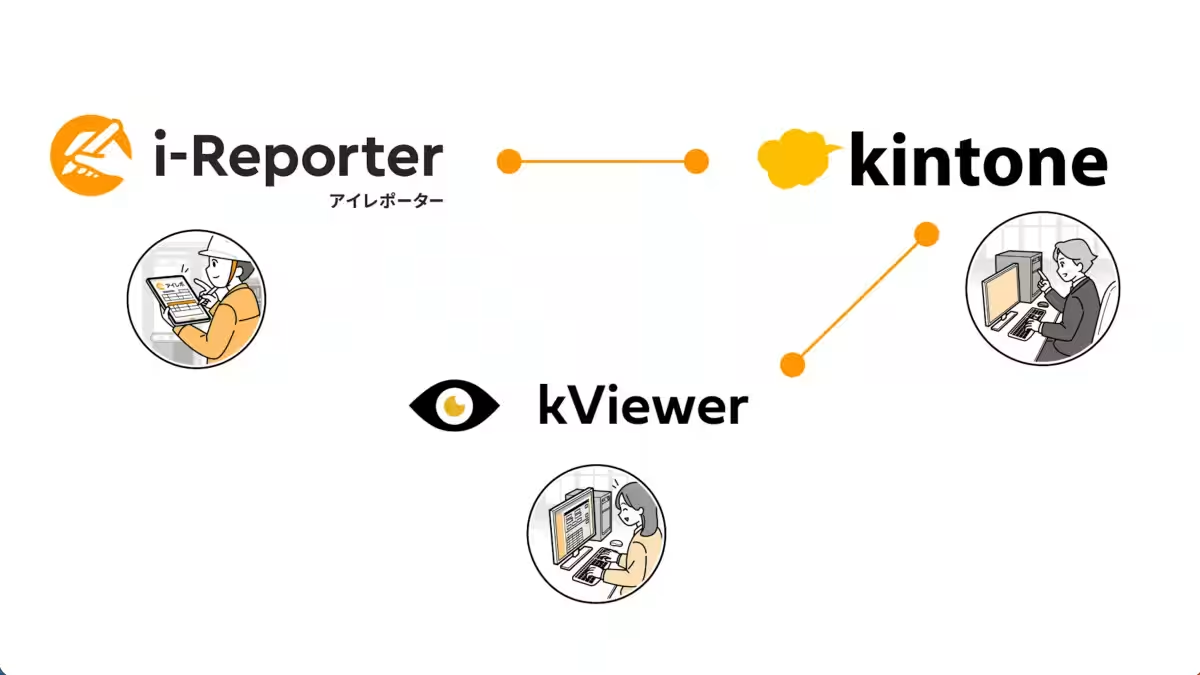

To tackle these inefficiencies, Kyushu Yanagawa Seiki implemented the i-Reporter system in 2021, establishing a seamless integration with kintone and kViewer. This trio of systems allowed them to clearly assign roles and successfully drive digital transformation on-site.

Implementation of Systems

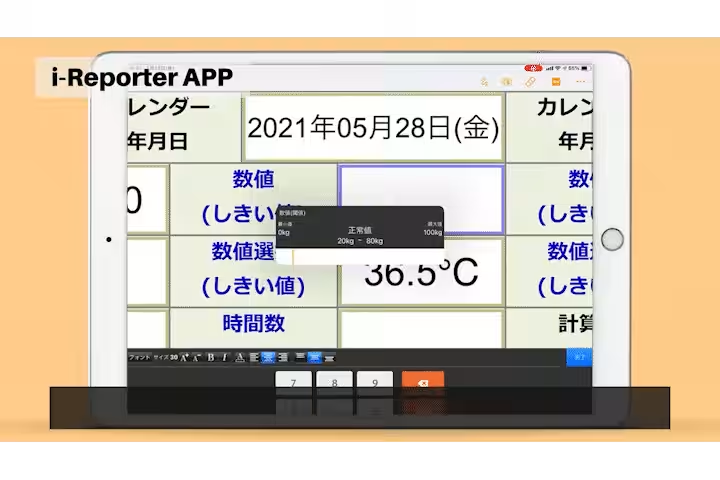

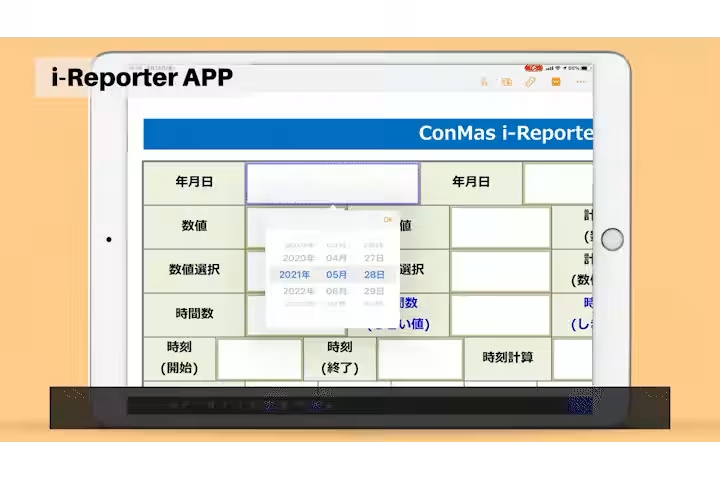

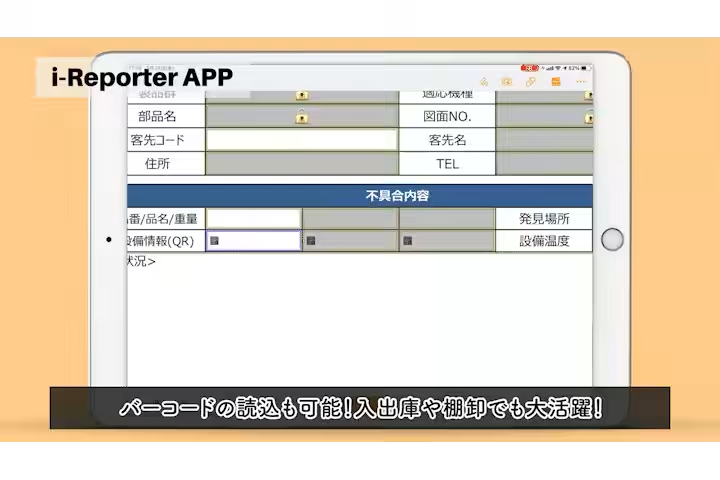

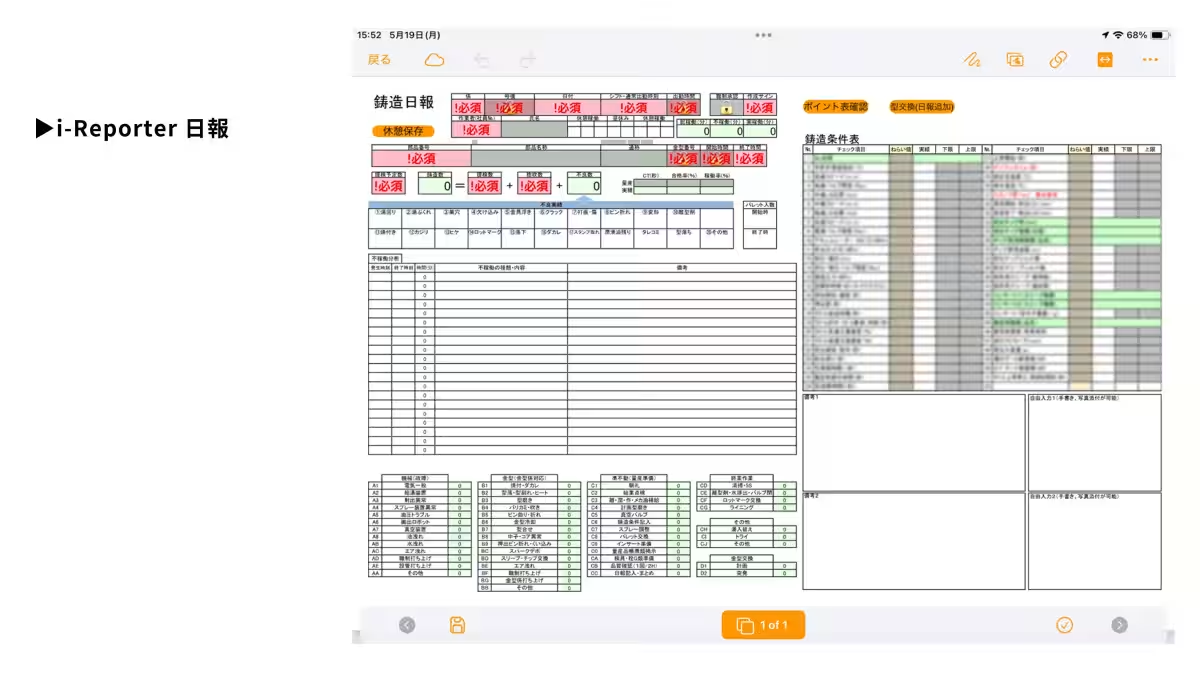

i-Reporter

This tailored interface for on-site input facilitates efficient data collection regarding business performance through various input functions.

kintone

Serving as a database, kintone manages and accumulates data for parts master records, budgets, stock, and daily reports.

kViewer

Used as a visualization tool, kViewer enables all staff to instantly view and make informed decisions based on real-time data.

Key Benefits

1. Improvement of Work Reports

The introduction of i-Reporter eliminated the six hours previously spent on processing work reports for 190 lines. Data entered via iPads is now instantly linked to kintone, allowing real-time availability for managers and other departments. This has not only minimized errors like omissions and misentries but significantly accelerated improvement initiatives. Both on-site staff and management now share the same up-to-date information instantly, enhancing collaboration and efficiency.

- - Impact: Elimination of six hours of work report processing.

- - Outcome: Information sharing that once took 1-2 days is now completed within the same day, accelerating quality improvement activities.

2. Enhancement of the Painting Line Management

Transitioning from handwritten daily reports to real-time data input has transformed the oversight of the 200-meter painting line. Each task's data is now rapidly relayed, enabling downstream personnel to monitor progress on their iPads.

- - Impact: Immediate visibility of the painting line status.

- - Outcome: Graphical representation of KPIs has fostered efficiency improvements in hanger management and workflow.

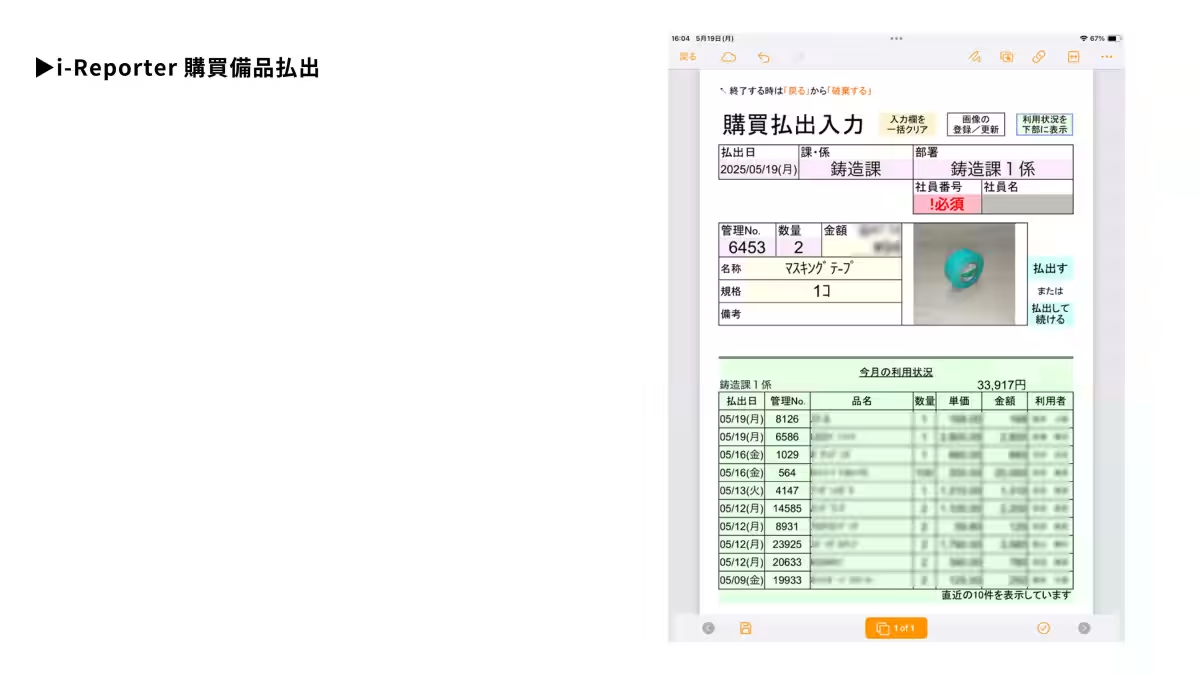

3. Streamlining Equipment Dispatch Input

Previously requiring 2.5 hours monthly for equipment dispatch input and aggregation, this task has been completely eliminated. Entering department and management numbers in i-Reporter auto-displays names and unit costs, instantly relaying data to kintone.

- - Impact: Reduction of 2.5 hours in input and aggregation tasks.

- - Outcome: Greater cost awareness among teams, reducing unnecessary orders.

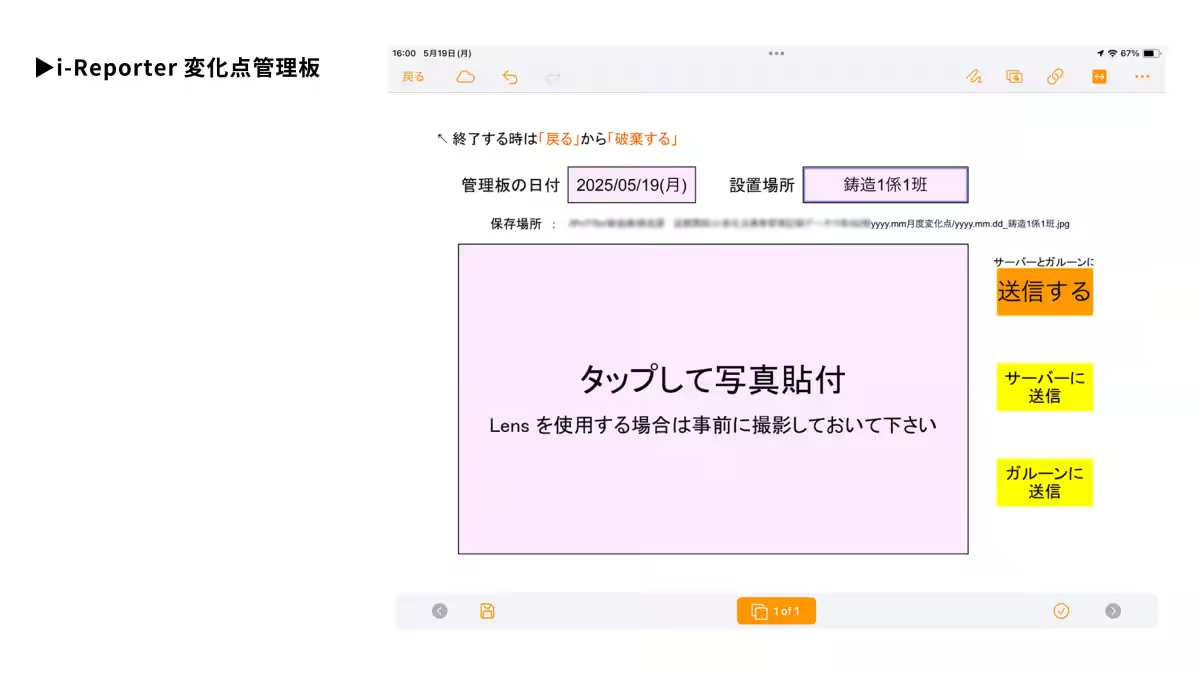

4. Optimization of Change Point Management

The daily burden of saving photos for 23 management boards, which took up to one hour, has been eradicated. i-Reporter simplifies the process of selecting dates and installation locations for photo saves.

- - Impact: Elimination of one hour of photo organization work daily.

- - Outcome: All departments can now view management boards on a single screen, drastically improving quality management and enhancement activities.

Future Outlook

Kyushu Yanagawa Seiki is well-positioned for continued growth and development through its flexible use of digital tools, driven by the i-Reporter system. Ongoing enhancements are anticipated, ultimately boosting operational efficiency and field capabilities.

Company Overview

Kyushu Yanagawa Seiki Co., Ltd.

- - Founded: 1976

- - Headquarters: 1106-1, Asahi Shikawa, Kikuchi City, Kumamoto Prefecture, Japan, 869-1205

- - Industry: Manufacturing of transportation machinery and equipment

- - Main Products: Aluminum die-cast parts for motorcycles and automobiles

- - Official Website: Kyushu Yanagawa Official Site

Conclusion

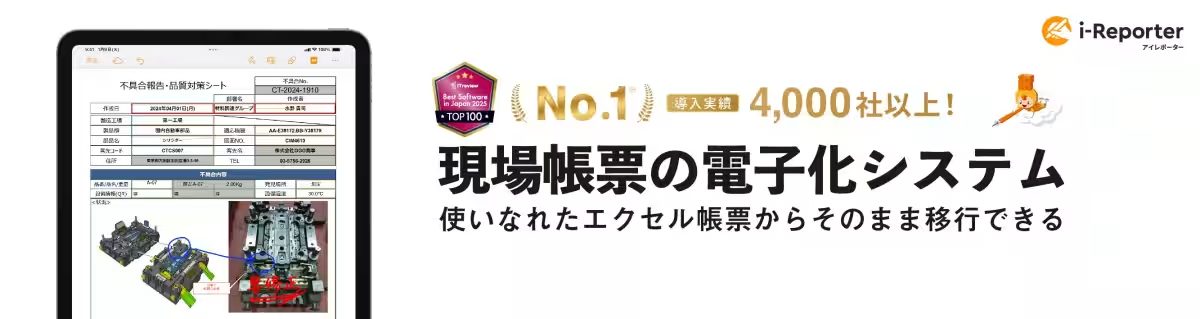

With over 21,000 users across 4,500 companies, i-Reporter showcases its leading position in the market for digitizing field reports. From paperwork reduction to automation, its implementation yields significant benefits, streamlining on-site operations and enhancing overall productivity. Companies looking for similar transformations might certainly draw inspiration from Kyushu Yanagawa Seiki's successful case.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.