Hitachi Launches Recycling Network for Elevator Permanent Magnet Motors

Hitachi's Groundbreaking Recycling Initiative

Hitachi, along with its subsidiaries Hitachi Building Systems and Nichiwa Service, has recently initiated a significant step towards sustainability by launching a recycling network for permanent magnet motors used in its elevators. This effort aligns with Hitachi's new management strategy, Inspire 2027, which aims to foster a circular economy as part of its sustainability initiative, known as PLEDGES.

The introduction of this recycling system is critical for promoting the circular use of rare earth materials, thereby reducing the environmental burden associated with industrial processes. Through its commitment to the circular economy, Hitachi is pioneering solutions to enhance resource cycles within its operational framework.

A Focus on Resource Efficiency

The Circular Economy strategy at Hitachi is not merely a theoretical framework; it is grounded in practical applications and innovative technologies. The company recognizes the rotating machinery sector as a focal point for advancing these efforts, particularly through the recycling of permanent magnet motors in a variety of applications including elevators, electric vehicles, and generators.

As the demand for such motors continues to grow, the need for effective recycling practices becomes more urgent. Between 1999 and the present, permanent magnet motors have been installed in Hitachi's machine-room-less elevators, which are now facing their renewal period. Given that the average lifespan for elevators is about 17 years, many of these units are coming due for upgrade, thereby providing an opportune moment for recycling efforts to expand.

Expanding Innovative Practices

The collaborative approach taken by the CI (Connected Industries) sector of Hitachi represents a robust model for integrating digital technology with resource management. Hitachi Building Systems is committed to evolving its elevator and escalator services into digitized asset offerings, embodying the Lumada 3.0 platform, which focuses on enhancing maintenance quality and operational efficiency.

Notably, the company forecasts an increase in recyclable materials from 80 tons to approximately 650 tons annually as the renewal of elevator systems accelerates. This ambitious projection aims to not only enhance recycling efforts but also to support broader sustainability goals by incorporating additional industrial motors into the recycling program.

Structured Recovery Processes

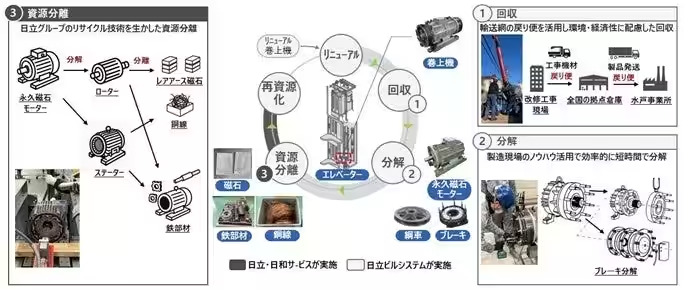

1. Efficient Collection through Supply Chain:

Utilizing Hitachi Building Systems' supply chain, the company has designed an efficient recovery process for these large industrial motors. By integrating return deliveries from product shipments, the necessity for dedicated transport trucks is minimized, thus reducing environmental impact.

2. Streamlined Disassembly with Expert Knowledge:

The disassembly of permanent magnet motors requires an intricate understanding of their construction. To augment this process, a dedicated workspace for the disassembly of these motors has been established at Hitachi's Mito plant. Here, skilled technicians utilize their experience to ensure an efficient and effective disassembly process.

3. Specialized Resource Separation Techniques:

The intricate nature of these motors necessitates advanced techniques for resource separation, particularly for rare earth magnets embedded within the components. Leveraging its knowledge of recycling across both domestic and industrial sectors, Hitachi's Water and Environment Business Unit, in collaboration with Nichiwa Service, has developed specialized techniques for extracting these valuable materials.

The ultimate goal of these recycling efforts is twofold: to sustain the planet's resources and simultaneously ensure Hitachi's long-term growth and viability. This initiative is emblematic of Hitachi’s commitment to a harmonized society where environmental sustainability and economic growth coexist.

A Vision for the Future

Hitachi’s CI sector is not just about products; it’s about fostering growth through sustainable innovation. The integration of extensive data from digitalized assets combined with advanced artificial intelligence through services like HMAX Industry is part of a broader vision of sustainable industrial automation.

In conclusion, this recycling initiative by Hitachi represents a crucial endeavor towards enabling an efficient circular economy, significantly contributing to reductions in waste and the promotion of resource sustainability within the industrial sector. As Hitachi continues to develop and refine its recycling methods for permanent magnet motors, it not only addresses pressing environmental concerns but also advances the company's strategies for growth and innovation.

Further Information

For more details about Hitachi and its sustainability efforts, please visit their official sites:

As we look towards a future defined by sustainability, Hitachi stands at the forefront of creating effective, innovative solutions that benefit both the environment and society at large.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.