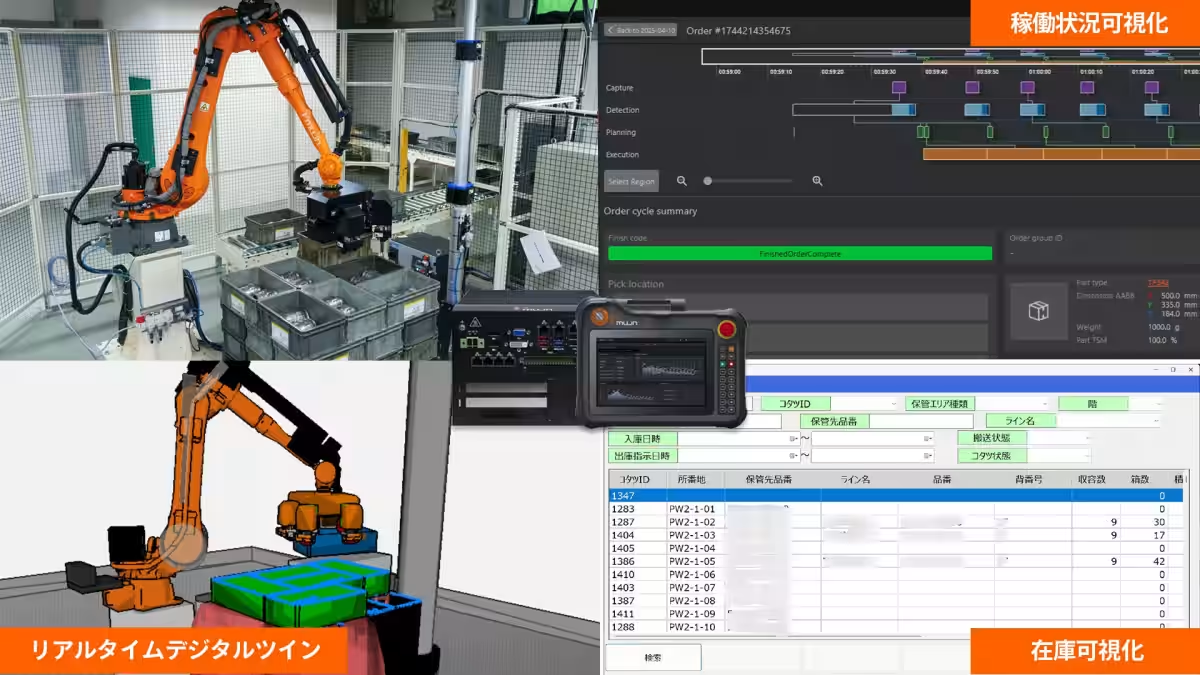

Revolutionizing Logistics: Mujin Enhances Sango's Factory Operations with Next-Gen Robots and Digital Twin Technology

Revolutionizing Factory Logistics with Mujin

Introduction

In a significant leap forward for automotive manufacturing, Mujin has partnered with Sango Co., Ltd. to digitize and optimize the logistics of their factory operations using state-of-the-art intelligent robots and digital twin technology. This advancement supports Sango’s ongoing production ramp-up in automotive body parts, while effectively reducing logistics costs.

The Shift Towards Digitization

Traditionally, Sango's logistics involved storing finished products in an external warehouse before transporting them back to the factory for shipping. Given the worsening shortage of labor and rising logistics expenses, Sango recognized the urgent need for a more efficient logistics system. This prompted them to collaborate with Mujin, initiating a project aimed at constructing an on-site automated product warehouse with cutting-edge robotics.

The key highlights of this transformation at Sango include:

1. Reduction in Logistics Costs and Environmental Impact

- - Through logistics optimization, Sango has achieved a reduction of ¥140 million in the first year of logistics costs and a decrease in labor hours by 67% in handling operations.

- - The integration of automation has led to a staggering cut of 2,080 truck trips yearly between the external warehouse and the factory, which means an annual reduction of 11.9 tons of greenhouse gas emissions, thus demonstrating Sango’s commitment to environmental stewardship.

- - Enhanced visibility of field operations and inventory data through digital twin technology has streamlined inventory management, preventing overproduction.

2. Focusing Resources on High-Value Manufacturing Tasks

- - As labor issues are anticipated to worsen in the future, the workforce previously assigned to logistics has now been redeployed to more strategic, high-value manufacturing projects.

- - By automating tasks such as the handling of heavy boxes, weighing up to 15 kg each, Mujin's solution alleviates around 18 tons of manual handling burden per worker each day, enhancing overall employee productivity.

Mujin's Role in the Digital Transformation

At the core of this innovative transition is Mujin's robust understanding of automation and digital twin technology. These solutions provide real-time integration and management of intelligent robots, AGVs, safety devices, and various transportation systems, all through a unified Warehouse Control System (WCS). This integration allows for optimal equipment collaboration and immediate visibility of operational status and inventory levels, enabling rapid troubleshooting and effective remote support in case of any issues.

Advancements in Automation Technology

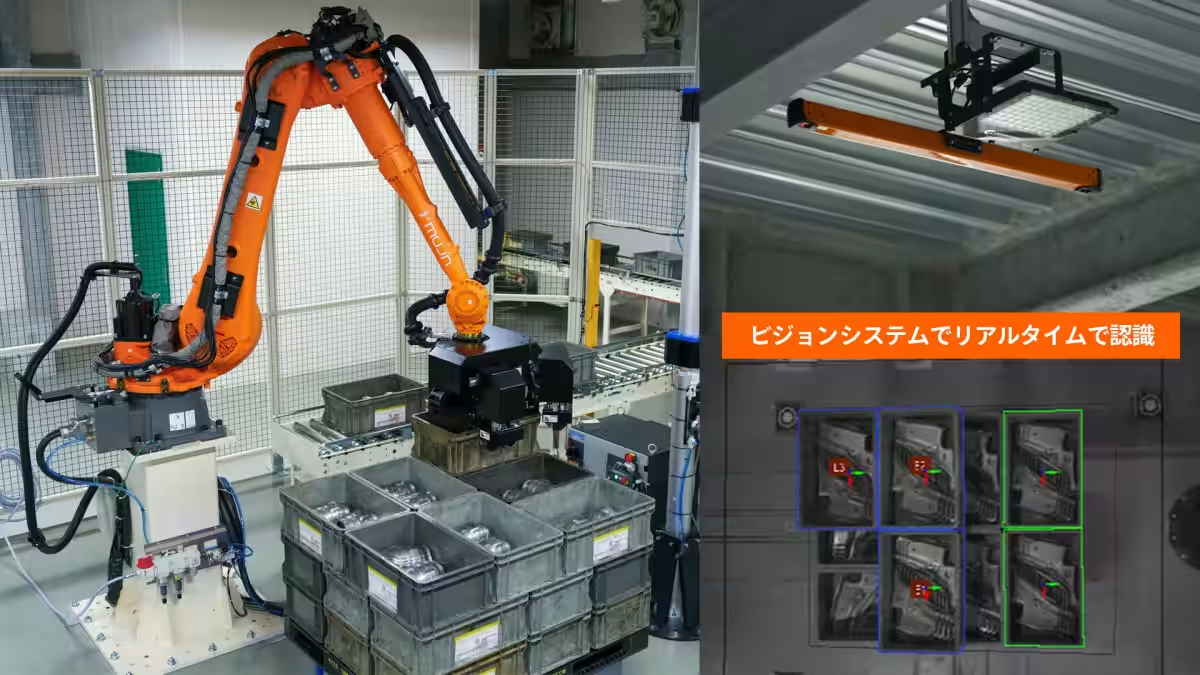

Mujin’s intelligent robots and AGVs are engineered to adapt seamlessly to the manufacturing environment. Key technological advancements include:

- - A 3D vision system specially designed for factory automation ensures stable operations while handling various types of boxes, surpassing the limitations of traditional teaching-based robots.

- - A self-developed gripping mechanism that accommodates over 50 different types of crates, facilitating flexibility in the automation process.

- - Smooth coordination between AGVs and intelligent robots, ensuring operational efficiency in handling logistics tasks.

Conclusion

This exciting venture has not only enhanced Sango's factory logistics but has also set a precedence for future automation solutions across other factories. Mujin’s next-generation factory logistics DX, rooted in innovative software solutions, is paving the way for Sango and beyond to embrace the future of automotive manufacturing.

For further details, visit the following links:

Company Profiles

Sango Co., Ltd.

- - Founded: 1950

- - CEO: Akito Mizuno

- - Website: sango.jp

Sango specializes in the development and manufacturing of exhaust systems and pressed parts for automotive applications, embodying the ethos of connecting people and the environment through manufacturing.

Mujin Japan Co., Ltd.

- - Started Operations: April 2024

- - CEO: Yutaka Arase

- - Website: mujin.co.jp

Mujin aims to revolutionize modern factories and warehouses by providing a unique integrated automation platform that employs intelligent robots and AGVs, delivering state-of-the-art automation solutions in production and logistics.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.